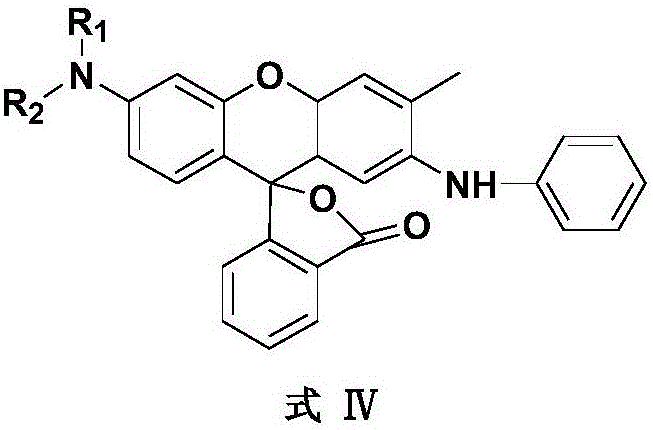

Method for preparing black fluorane thermopressure-sensitive dye by one-step method

A fluorane-based, thermal and pressure-sensitive technology, which is applied in the direction of azo dyes, organic dyes, chemical instruments and methods, etc., can solve the problems of cumbersome production process, large discharge of waste acid and waste alkali, and long time consumption, so as to avoid Local temperature is too high, the amount of sulfuric acid is reduced, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

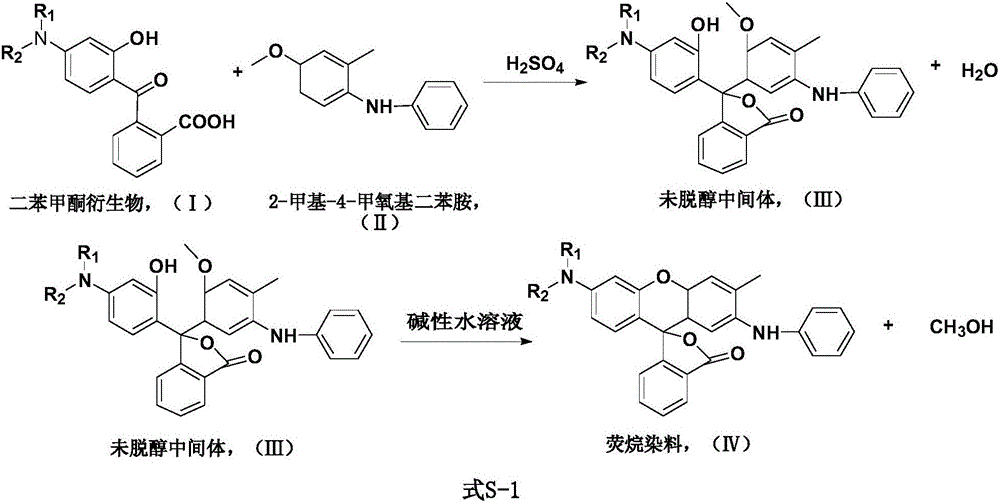

Method used

Image

Examples

Embodiment 1

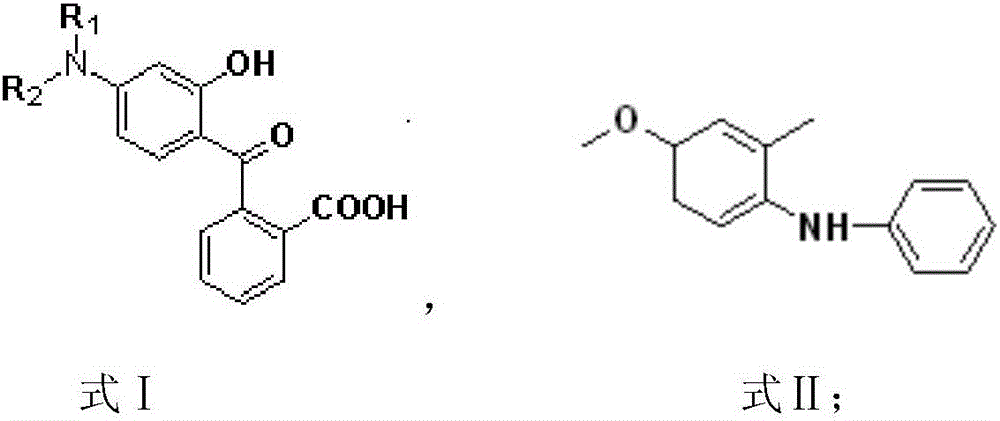

[0059] Embodiment 1, the method for preparing black fluoran class thermal pressure-sensitive dye by one-step method, carries out following steps successively:

[0060]1). Add 150mL of dichloromethane, 55.4g (0.15mol) of 2-carboxy-4'-dibutylamino-2'-hydroxybenzophenone and 2-methyl-4-methoxy into a 500mL four-neck flask 32g (0.15mol) of diphenylamine, and slowly add 40mL (about 73.5g) of 98% sulfuric acid dropwise under stirring conditions until all the materials are dissolved, and the temperature is kept below 35°C. After the dropwise addition, the temperature was raised to 40° C. for reflux reaction for 4.5 hours.

[0061] 2). Continue to stir after the reaction, slowly drop 150ml of water into the four-necked flask, and recover dichloromethane by exothermic, that is, control the temperature of the reaction solution at 65-70°C to distill and recover dichloromethane, and keep it warm for 30 minutes. Add 150mL of toluene, continue to heat up to 85-90°C and stir for 30 minutes,...

Embodiment 2

[0064] The dichloromethane in Example 1 was replaced with 1,1-dichloroethane, and the temperature was raised to 58° C. for reflux reaction for 3 hours. The rest was the same as in Example 1 to obtain 73.4 g of a white solid with a yield of 92%. As detected by HPLC, the content of the compound of formula IV in the product is >99.5%.

[0065] R in the benzophenone derivatives described in this example 1 , R 2 Both represent butyl. That is, the benzophenone derivative is 2-carboxy-4'-dibutylamino-2'-hydroxybenzophenone; the black fluoran-based heat pressure sensitive dye is 3-dibutylamino-6-methyl-7 -anilinofluorane.

Embodiment 3

[0067] The dichloromethane in Example 1 was replaced with chloroform, and the temperature was raised to 62° C. for reflux reaction for 2.5 hours. The rest was the same as in Example 1 to obtain 71.8 g of white solid with a yield of 90%. Checked by HPLC, the content of the compound of formula IV in the product is >99.5%.

[0068] R in the benzophenone derivatives described in this example 1 , R 2 Both represent butyl. That is, the benzophenone derivative is 2-carboxy-4'-dibutylamino-2'-hydroxybenzophenone; the black fluoran-based heat pressure sensitive dye is 3-dibutylamino-6-methyl-7 -anilinofluorane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com