Construction method for rigid frame bridge No.0 section non-welding support and structure

A construction method and support structure technology, applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of insufficient force on the support structure, non-reusable materials, long erection time of supports, etc., and achieve better bridge quality Guarantee, save labor costs, and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

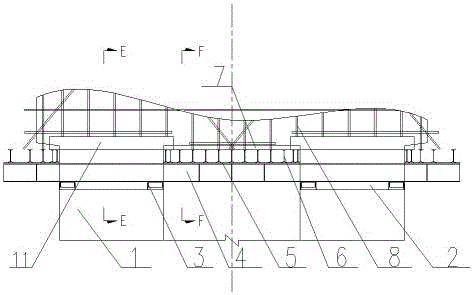

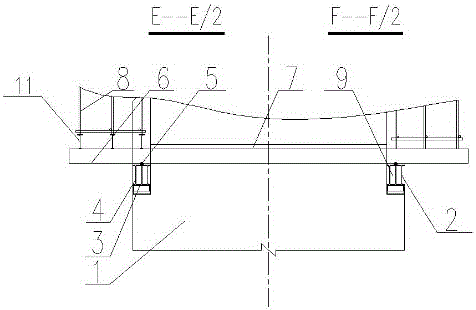

[0035] Embodiment of the present invention: a construction method for the No. 0 section of a rigid frame bridge without welded supports. When the left and right sides of the pier column are 40-60 cm wider than the bottom plate of the No. 0 section, this method can be used for construction. The construction method includes There are following steps:

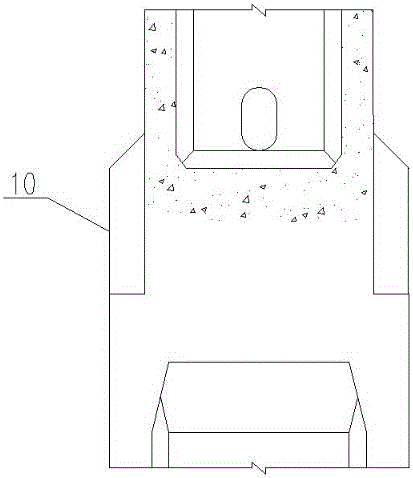

[0036] A. First pour the pier body, which is composed of two pier columns, namely A column and B column. There is a reserved space on both sides of the top of each pier for erecting supports;

[0037] B. Then level the fulcrum at the reserved space, place the sand cylinder, and adjust the elevation;

[0038] C. Then place 1 or 3 main longitudinal beams on each sand tube on both sides of the pier column. The main longitudinal beam spans 2 pier columns. The number of placement should be odd. If it is an even number, you need to do horizontal Allocation, which complicates the stent system;

[0039] D. Next, set a supporting steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com