Rigid frame bridge zero section support and construction method thereof

A construction method and technology for steel bridges, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as insufficient force on the support structure, non-reusable materials, and long erection time of supports, so as to save labor costs , Shorten the construction period, the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

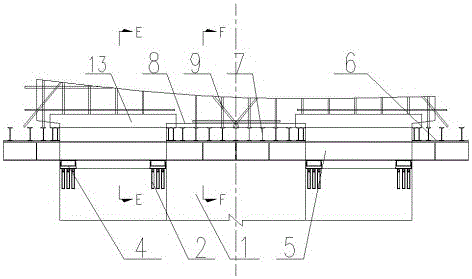

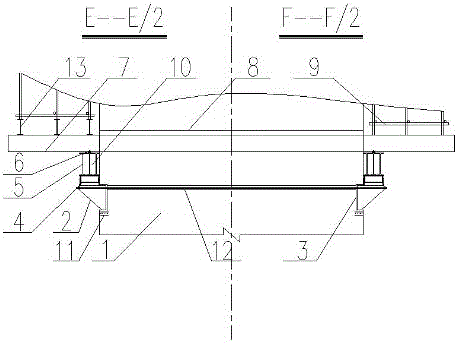

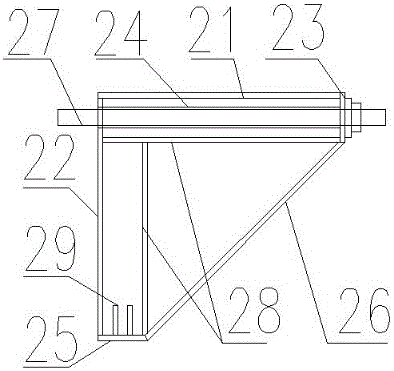

[0034] No. 0 section support of a steel structure bridge, as attached Figure 1~3 As shown, it includes a plurality of assembled corbels 2 arranged on both sides of two pier columns 1, and the assembled corbels 2 are installed in the embedded groove 3 provided on the pier body 1, and the corresponding part of the embedded groove 3 The pier column 1 is provided with a reserved hole 12, which can penetrate the embedded groove 3 on both sides of the pier column 1. After putting the assembled corbel 2 into the embedded groove 3, use a precision thread After the steel bars 27 pass through the two assembled corbels 2 on both sides of the pier column 1, they are pulled and fixed, so that the assembled corbels 2 can be fixed in the embedded groove 3, and several assembled corbels 2 are installed There is one sand cylinder 4, and one or three main longitudinal beams 5 are placed on the sand cylinder 4 on the same side of the two pier columns 1. The main longitudinal beam 5 spans the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com