Arrangement method and composition structure for rigid frame bridge zero section non-welded support

A non-welded, rigid-frame bridge technology, applied in bridge construction, bridges, bridge materials, etc., can solve problems such as insufficient force on the support structure, non-reusable materials, and long erection time of the support, so as to save labor costs and shorten the construction time. The construction period and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

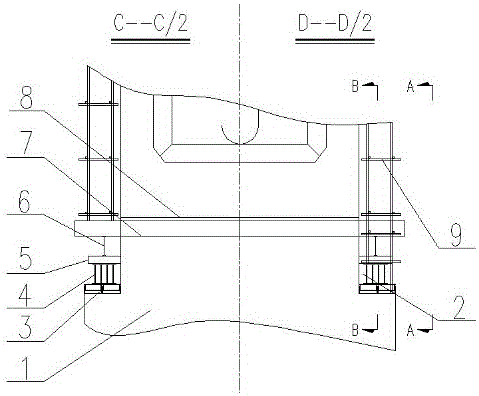

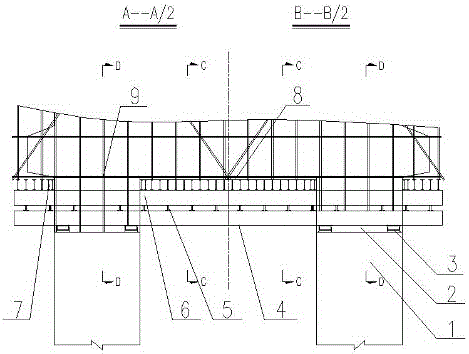

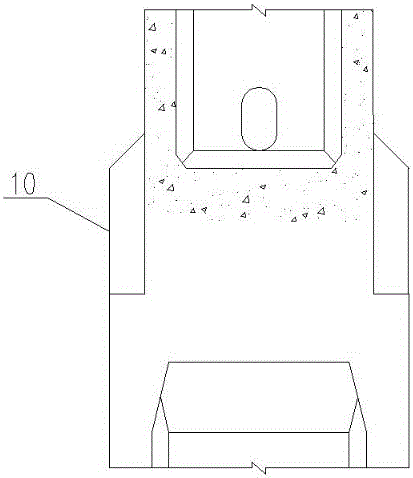

[0032] Embodiment of the present invention: a method for setting up the No. 0 section of a rigid frame bridge without welding supports. When the left and right sides of the pier column are wider than the bottom plate of the No. 0 section ≥ 80 cm, this method can be used for construction. The construction method includes: The following steps:

[0033] A. First pour the pier body, which is composed of two pier columns, namely A column and B column. There is a reserved space on both sides of the top of each pier for erecting supports;

[0034] B. Then level the fulcrum at the reserved space, place the sand cylinder, and adjust the elevation;

[0035] C. Then place more than 2 main longitudinal beams of the first layer side by side on each sand drum;

[0036] D. Then set multiple transverse distribution beams on the main longitudinal beams of the first floor;

[0037] E. Set up a second-story main longitudinal beam on the transverse distribution beam on each side of the pier co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com