A prefabricated beam-column joint-frame with side panels

A technology of prefabricating beams, columns and side panels, applied in the direction of building and building structure, can solve the problems of simplicity of mechanical properties of joints, inability to achieve both economy, poor quality of welds, and reduced service life of frames, etc. Inconsistency of beam and column dimensions, improving service life and ensuring the effect of weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

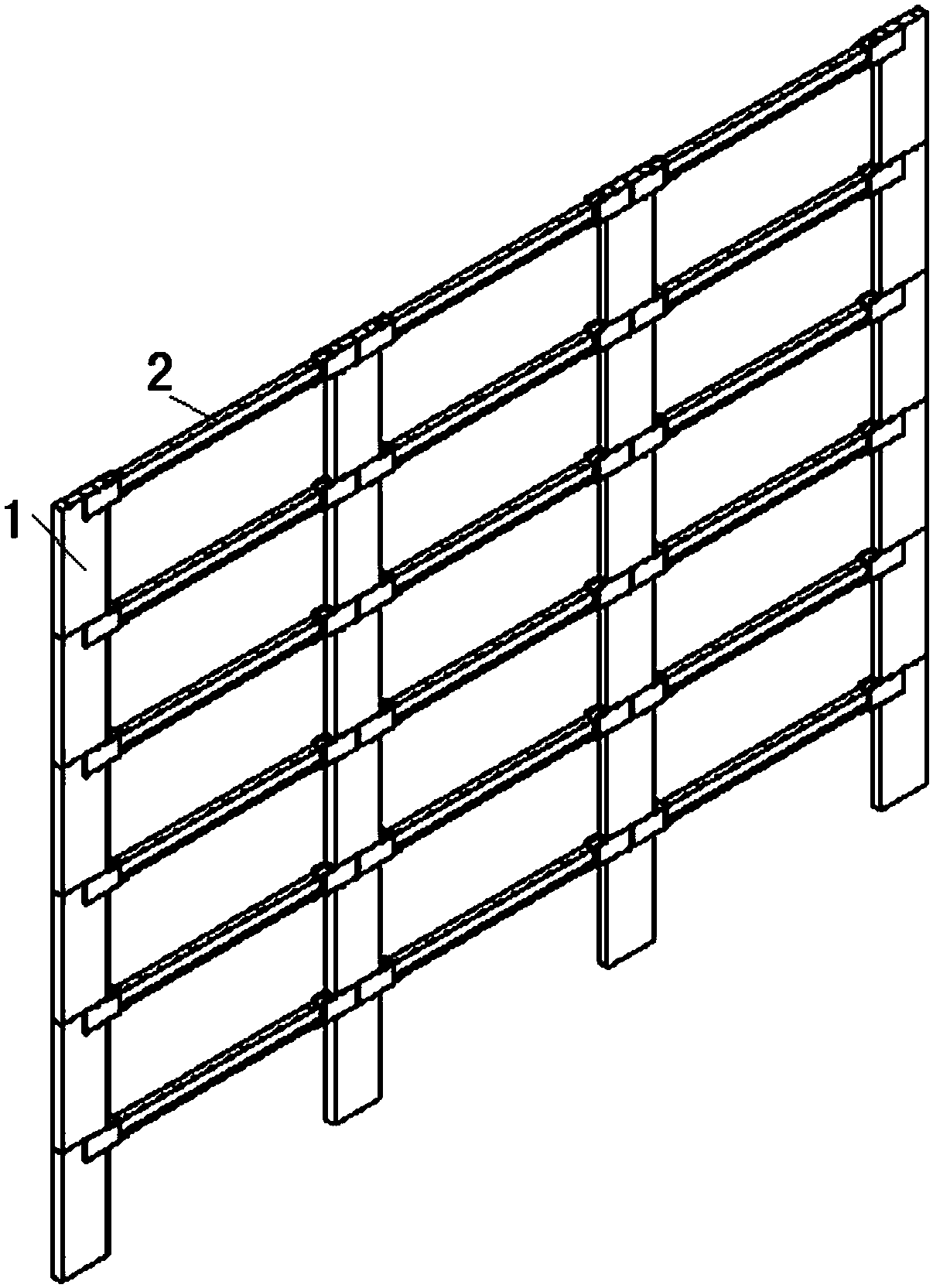

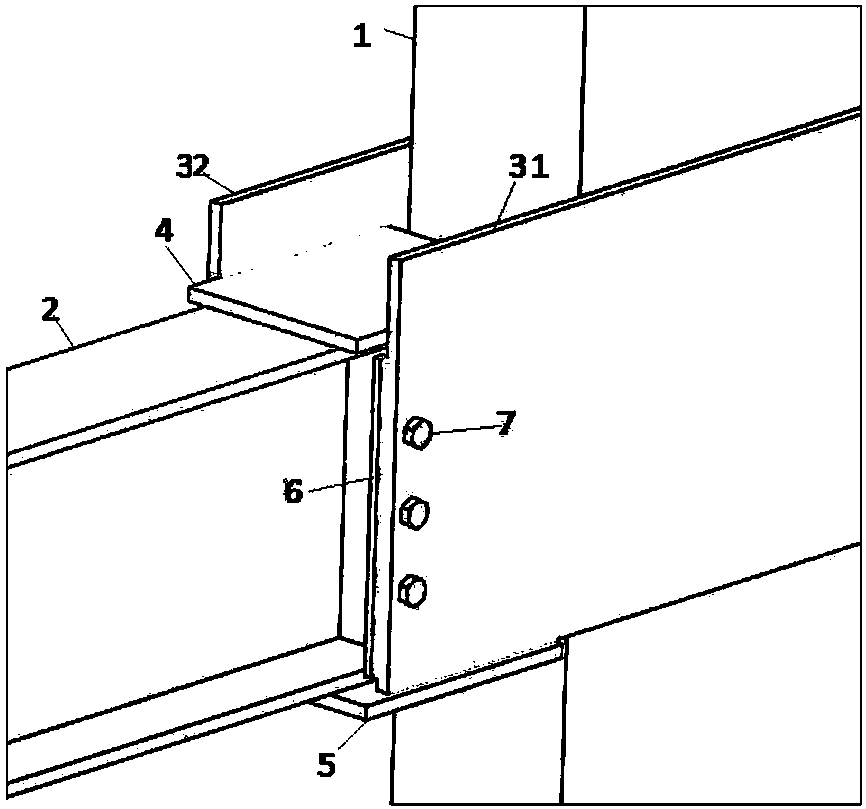

[0023] refer to figure 1 and figure 2 , the frame of the prefabricated beam-column joint with side plates according to the present invention comprises multi-cavity concrete-filled steel pipe composite columns 1 distributed sequentially from left to right, each multi-cavity steel pipe concrete composite column 1 is distributed in parallel, each multi-cavity steel pipe concrete composite The tops of the columns 1 are flush, and the bottoms of the multi-cavity concrete-filled steel pipe composite columns 1 are flush. Two adjacent multi-cavity concrete-filled steel pipe composite The H-shaped steel beams 2 between the concrete composite columns 1 are distributed in parallel; the cross-section of the multi-cavity steel tube concrete composite column 1 is rectangular, with a length of 8m and a width of 2m.

[0024] It should be noted that the H-shaped steel beam 2 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com