A space truss beam

A space truss and diagonal rib technology, applied in the field of space truss beams, can solve the problems of unreachable local bearing capacity, low buckling resistance of webs, and reduced web bearing capacity, etc., and achieve good local stability, engineering design and construction. Simple and effective in reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described with reference to the accompanying drawings.

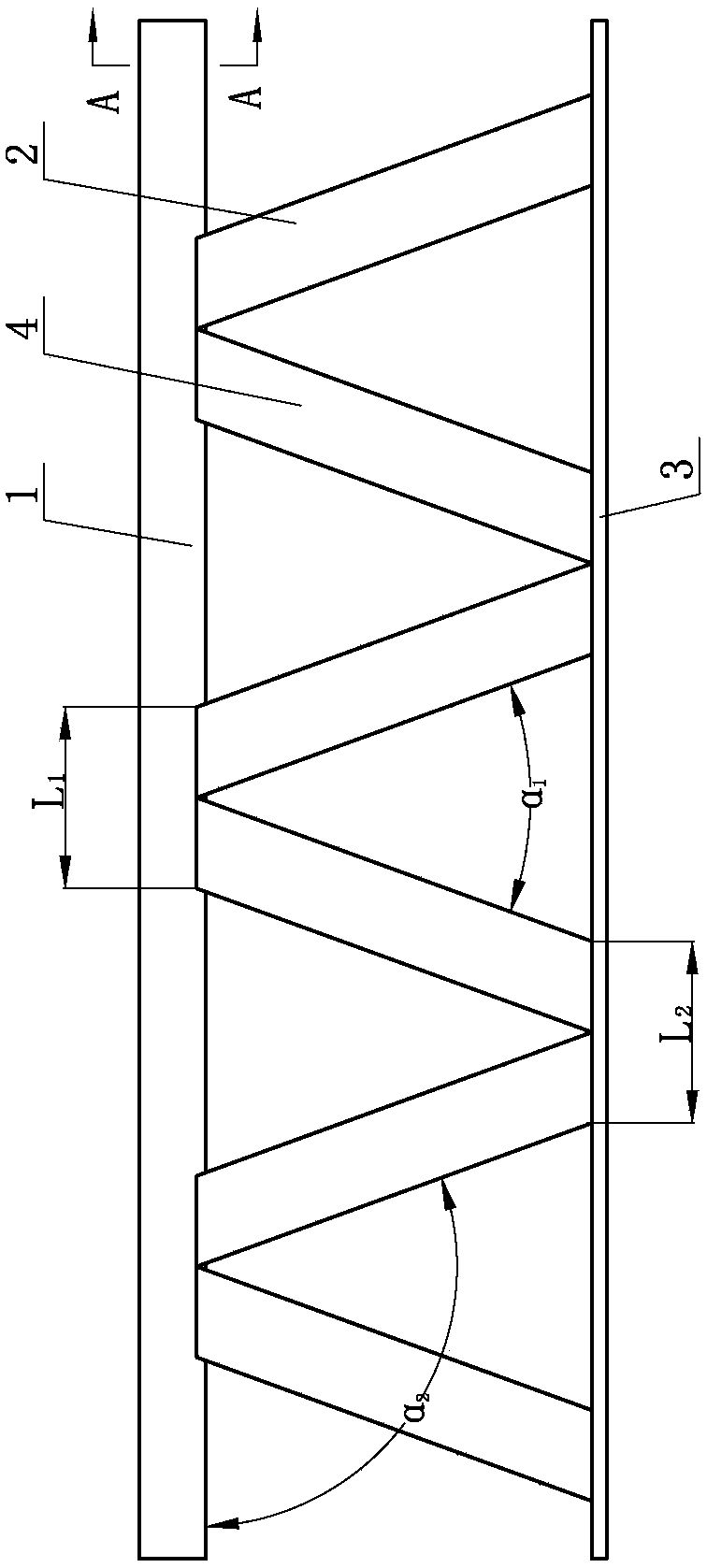

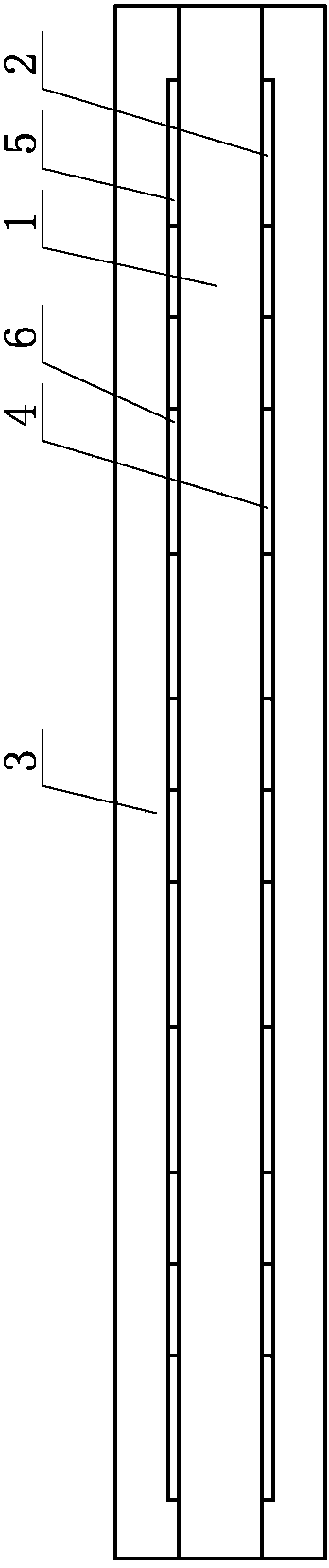

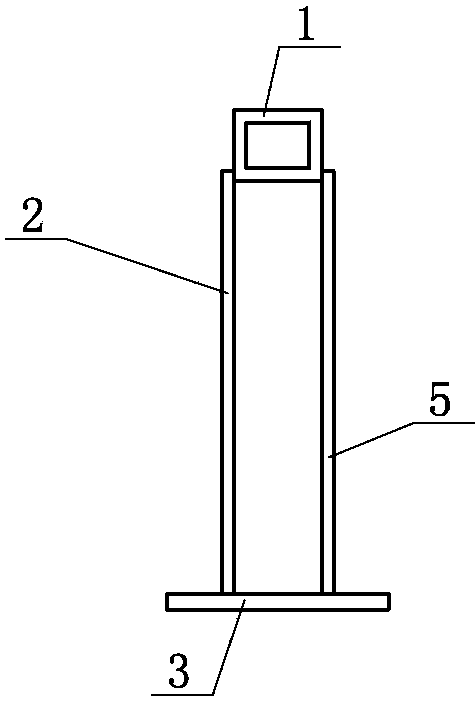

[0008] A space truss beam of the present invention comprises an upper wing bar 1 and a lower wing plate 3, the upper wing bar 1 and the lower wing plate 3 are parallel, and several first diagonal ribs 2 are connected between the upper wing bar 1 and the lower wing plate 3 , several second oblique ribs 4, several third oblique ribs 5 and several fourth oblique ribs 6, the lengths of each oblique ribs are equal, and several first oblique ribs 2 and several second oblique ribs 4 are located on the upper wing 1 on one side in the width direction, several third diagonal ribs 5 and several fourth diagonal ribs 6 are located on the other side of the upper wing bar 1 in the width direction, and a first clip is arranged between the first diagonal rib 2 and the second diagonal rib 4 Angle α 1 , the third angle α is set between the third oblique helper 5 and the fourth oblique rib 6 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com