Concrete automatic feeding and jetting device and concrete automatic feeding and jetting method

A technology of automatic reclaiming and spraying device, which is applied in earthwork drilling, shaft equipment, wellbore lining, etc., can solve the problems of improving the mechanization of sprayed concrete, and achieve the effect of liberating manpower loading operations, light weight and small dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

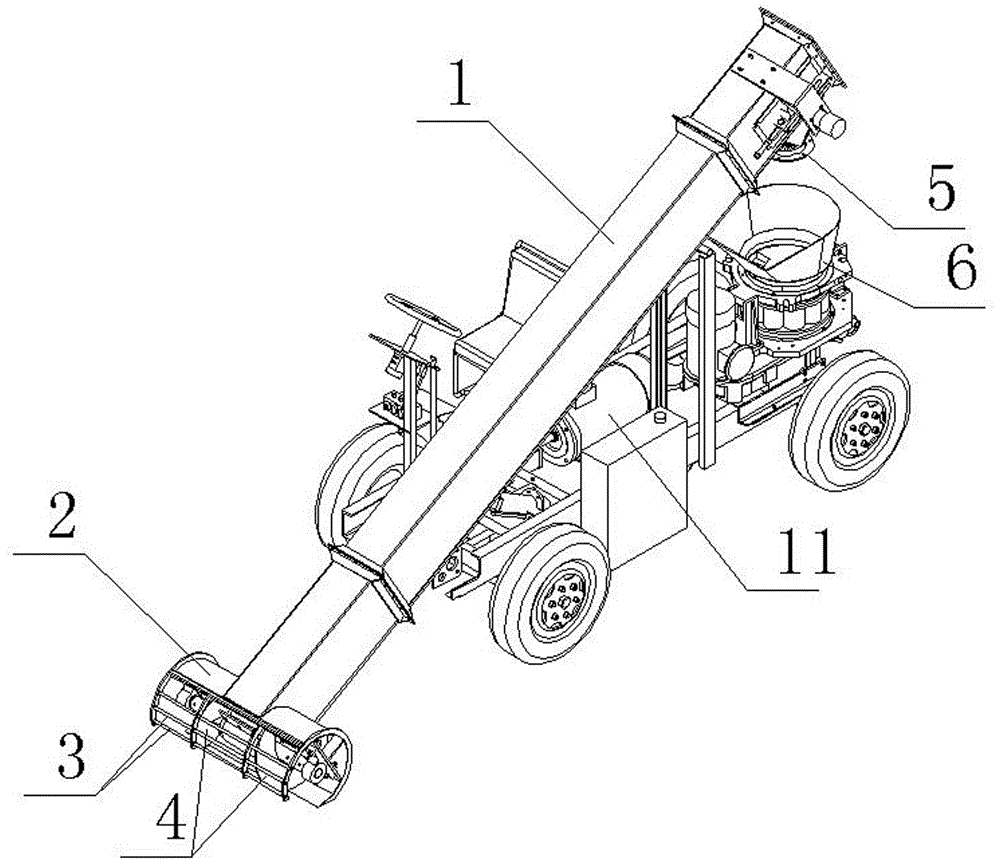

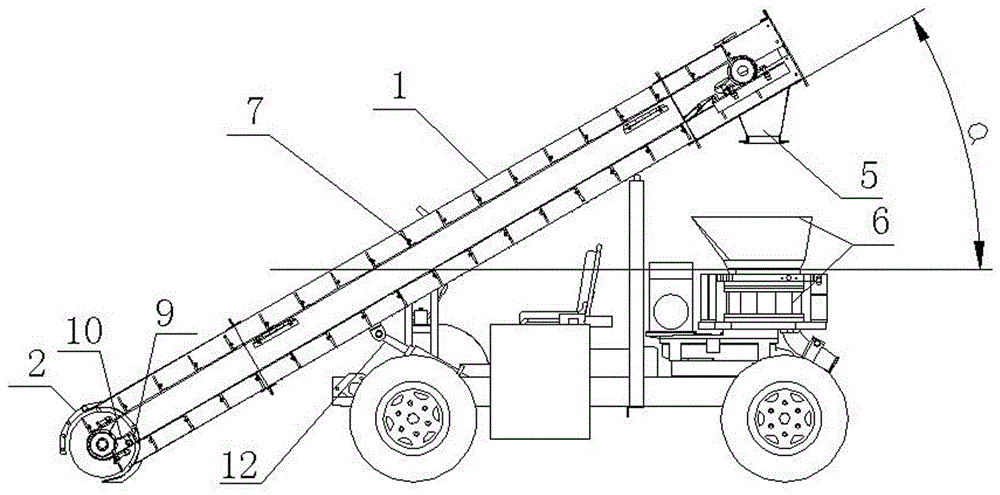

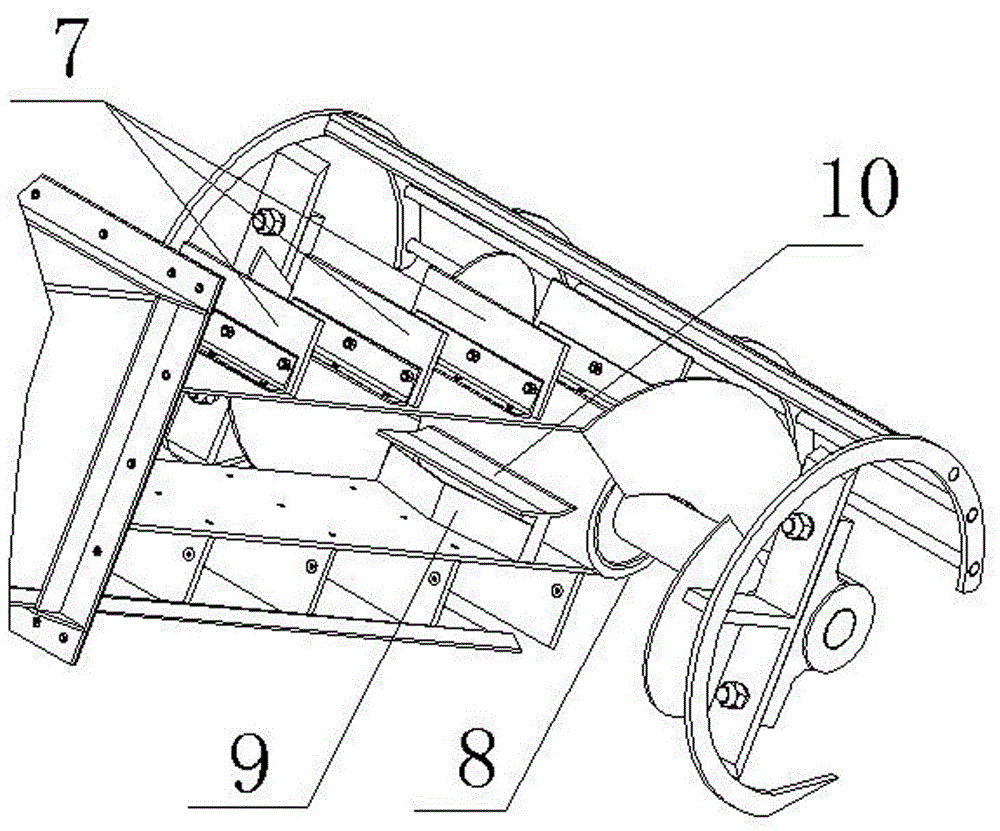

[0024] In the description of the drawings, the number 1 is a conveying device, 2 is a collecting device, 3 is a protective net, 4 is a spiral blade, 5 is a blanking port, 6 is a spray device, 7 is a wear-resistant scraper, and 8 is a conveying roller , 9 is a distribution device, 10 is a scraping device, 11 is a drive device, and 12 is a height automatic adjustment drive device.

[0025] The following is a further description of the concrete automatic reclaiming and spraying device and the concrete automatic reclaiming and spraying method of the present invention with reference to the drawings and specific embodiments: A concrete automatic reclaiming and spraying device, including a mobile frame, an aggregate device 2, and a conveying device 1 , The blanking port 5 and the driving device 11, the front of the mobile frame is equipped with a liftable conveying device 1, the front end of the conveying device 1 is fixed with a collecting device 2, and the rear end is connected with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com