Pressure feedback cylinder buffer device

A buffer device and feedback technology, applied in the direction of fluid pressure actuation device, servo motor assembly, mechanical equipment, etc., can solve the problems of poor self-adaptive ability, unable to realize self-adjusting buffer, etc., and achieve reasonable structure layout and strong practicability. , changing the effect of the buffer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

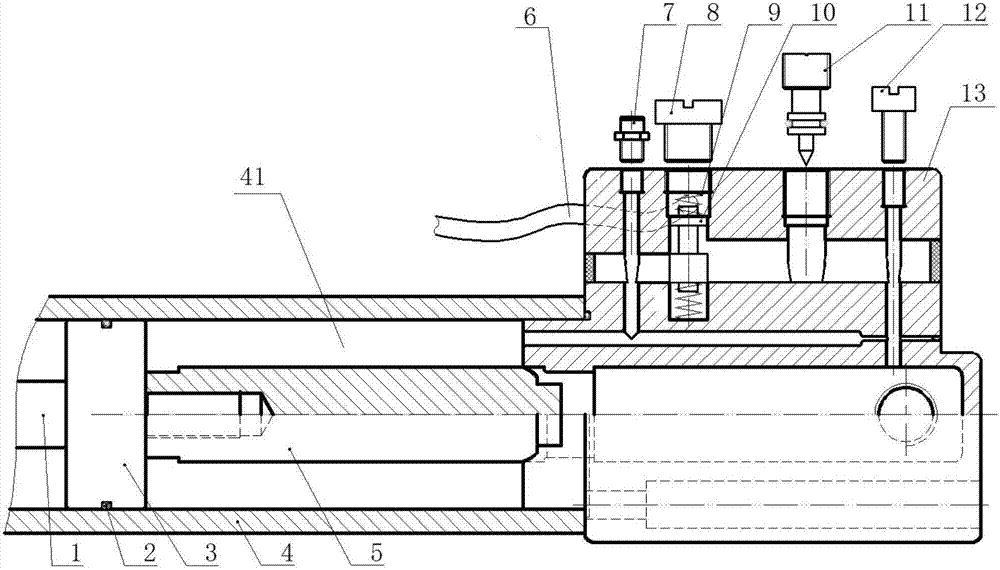

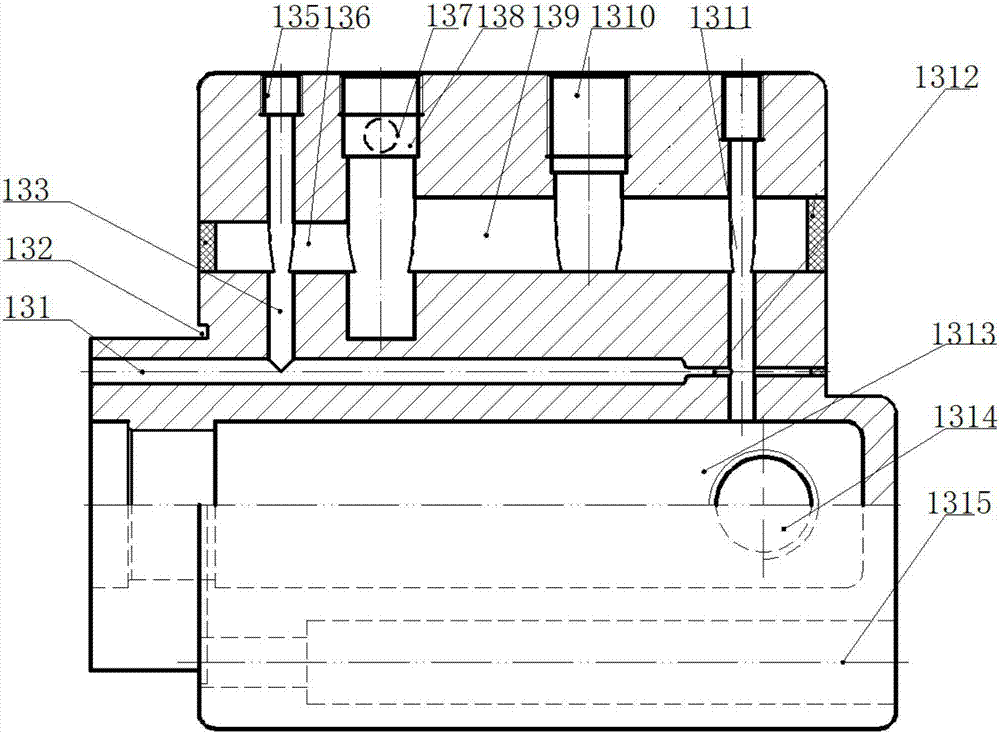

[0063] Embodiment 1, as shown in the figure, a pressure feedback type cylinder buffer device, including a buffer end cover 13 and a cylinder 4 fixedly installed at the front end of the buffer end cover 13, the buffer cavity 41 of the cylinder 4 A piston rod assembly 1 is installed.

[0064] The end cover body of the buffer end cap 13 is provided with a hexagon socket bolt through hole 1315 for connecting and fixing the buffer end cap 13 and its front end cylinder 4, and four screws pass between the buffer end cap 13 and the cylinder 4 Cooperate and fix, and install in the through hole 1315 of the inner hexagonal bolt. The main body of the buffer end cap 13 is provided with a seal ring installation groove 132 for sealing between the buffer end cap 13 and the cylinder barrel 4, and is installed in the seal ring installation The O-ring in the groove 132 ensures the sealing between the buffer end cover 13 and the cylinder tube 4 .

[0065] The piston rod assembly 1 includes a pis...

Embodiment 2

[0073] Embodiment 2, as shown in the figure, a pressure feedback cylinder buffer device, including a buffer end cap 13 and a cylinder 4 fixedly installed at the front end of the buffer end cap 13, the buffer chamber 41 of the cylinder 4 A piston rod assembly 1 is installed.

[0074]The end cover body of the buffer end cap 13 is provided with a hexagon socket bolt through hole 1315 for connecting and fixing the buffer end cap 13 and its front end cylinder 4, and four screws pass between the buffer end cap 13 and the cylinder 4 Cooperate and fix, and install in the through hole 1315 of the inner hexagonal bolt. The main body of the buffer end cap 13 is provided with a seal ring installation groove 132 for sealing between the buffer end cap 13 and the cylinder barrel 4, and is installed in the seal ring installation The O-ring in the groove 132 ensures the sealing between the buffer end cover 13 and the cylinder tube 4 .

[0075] The piston rod assembly 1 includes a piston 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com