NTC heat-sensitive chip testing method

A test method and chip technology, applied in thermometer test/calibration, heat measurement, measurement device, etc., can solve the problem of large hidden danger of misjudgment, avoid manual misjudgment, avoid product contamination, and improve test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

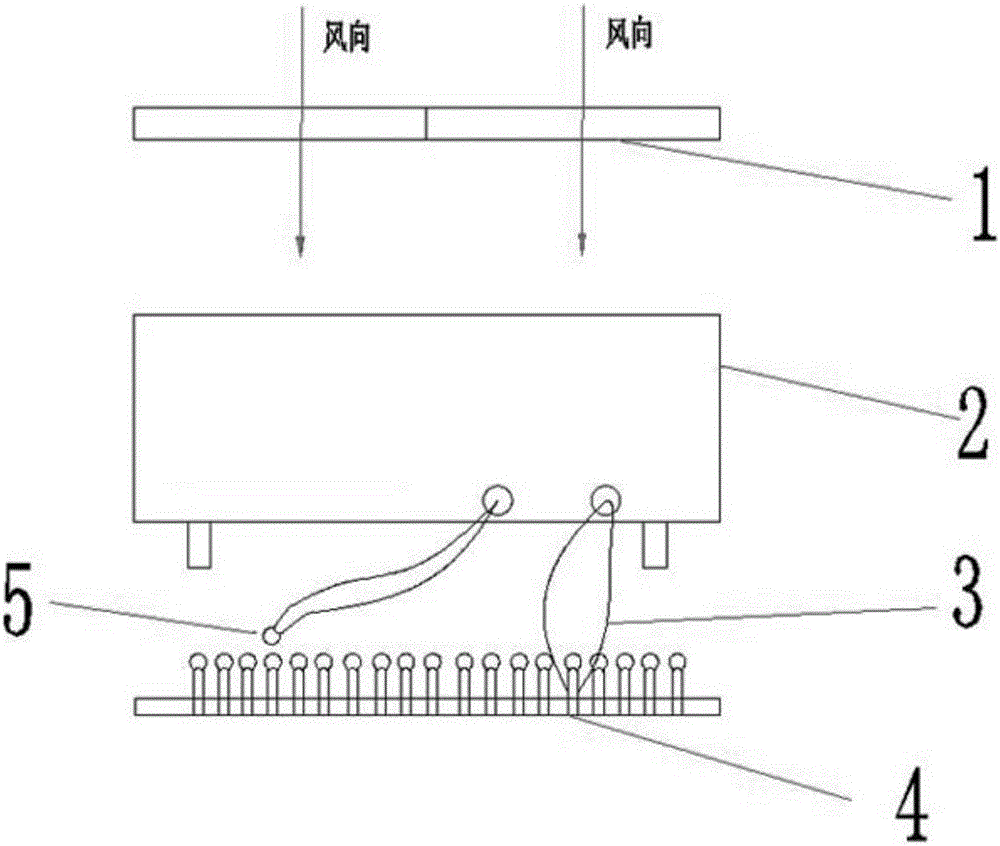

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] NTC thermosensitive chip test method of the present invention, concrete steps are as follows:

[0016] 1. Using the oil tank test method commonly used in the prior art, find a product with a resistance value close to the center value RS of the product specification in the same batch of products to be tested, record the resistance value, and use it as a benchmark product; search for a product in the same environment For a product whose resistance value is close to the lower limit or upper limit of the specification of this batch of products, record the resistance value as RC as the limit product. Calculate the deviation C between the limit product resistance value and the standard central value RS, C=RC / RS-1.

[0017] 2. Connect the reference product to the reference terminal of the thermistor tester and the limit product to the test terminal of the HG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com