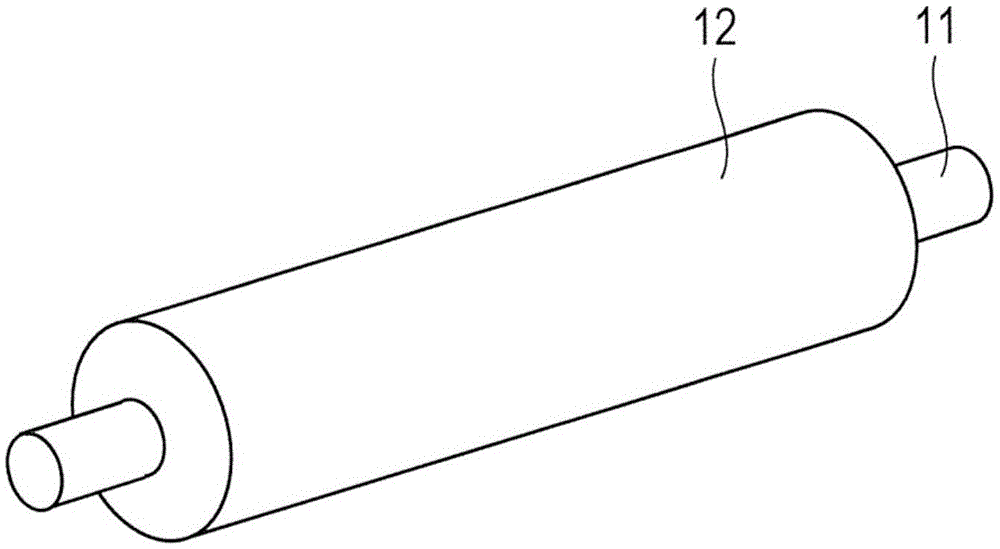

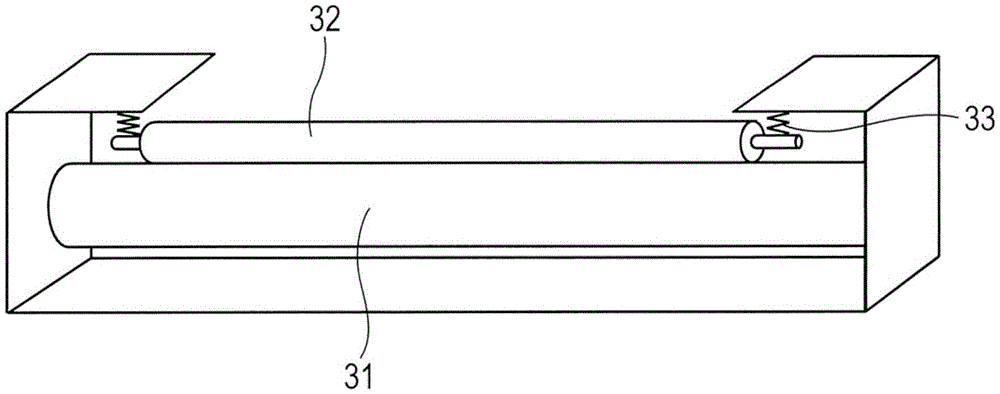

Roller for electrophotography and production method thereof, and electrophotographic image forming apparatus

A technology of electrophotography and manufacturing method, applied to the equipment of the electric recording process using the charge pattern, the electric recording process using the charge pattern, the electric recording technique, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] (Preparation of Unvulcanized Rubber Composition)

[0112] and were added to , and a 7-L internal mixer (trade name: WDS7-30: Nihon Spindle Manufacturing Co., Ltd. (former company name : manufactured by Moriyama Corporation) was kneaded for 7 minutes at a rotor speed of 30 rpm.

[0113]

[0114] - Acrylonitrile-butadiene rubber (Nipol DN401LL: Zeon Corporation):

[0115] 68 parts by mass

[0116] -Epichlorohydrin / ethylene oxide / allyl glycidyl ether terpolymer containing 56.7% by mass of ethylene oxide (EPION301: Daiso Co., Ltd. (new company name: Osaka Soda Co., Ltd.)) :

[0117] 22 parts by mass

[0118] - Epichlorohydrin / ethylene oxide / allyl glycidyl ether terpolymer containing 37.2% by mass of ethylene oxide (Epichlomer CG102: Daiso Co., Ltd. (new company name: Osaka Soda Co., Ltd.) ):

[0119] 10 parts by mass

[0120]

[0121] - Carbon black (Asahi #35G: Asahi Carbon Co., Ltd.) 45 parts by mass

[0122]

Embodiment 2

[0180] In addition to adding 22 parts by mass of epichlorohydrin / ethylene oxide / allyl glycidyl ether terpolymer ("EPION301") containing 56.7 mass% of ethylene oxide, Daiso Co., Ltd. (new company name: OsakaSoda Co., Ltd. ., Ltd.) and 10 parts by mass of epichlorohydrin / ethylene oxide / allyl glycidyl ether terpolymer ("HydrinT3106S", Zeon Corporation) containing 37.2 mass% of ethylene oxide for alcohol rubber Except, in the same manner as in Example 1, a roller for electrophotography of Example 2 was obtained.

Embodiment 3

[0182] Except that 71 parts by mass of acrylonitrile-butadiene rubber ("Nipol DN401LL", Zeon Corporation) was used for the unvulcanized rubber and 29 parts by mass of epichlorohydrin / ethylene oxide / allyl shrinkage containing 56.7 mass% of ethylene oxide Glyceryl ether terpolymer (EPION301: manufactured by Daiso Co., Ltd. (new company name: Osaka Soda Co., Ltd.)) was used alone for alcohol rubber, and Examples were obtained in the same manner as in Example 1 3 rollers for electrophotography.

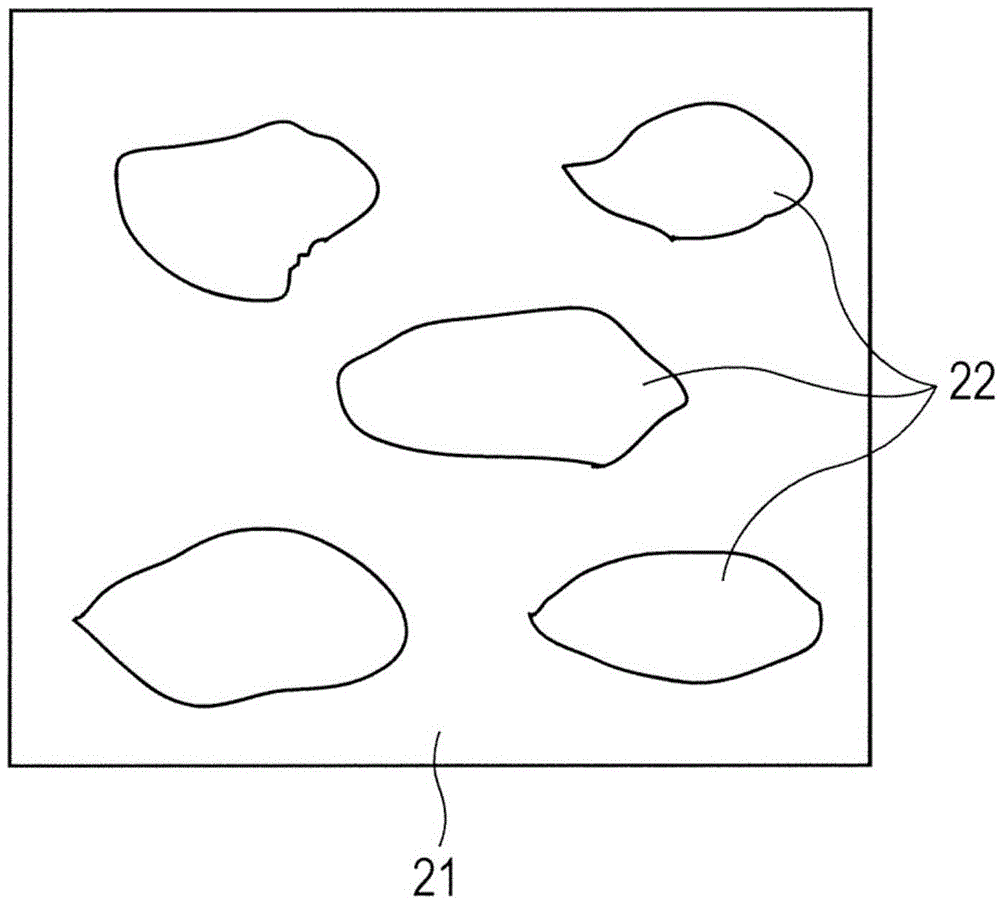

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com