Middle-large sized motor stator and rotor anti-gear swelling iron core

A large-scale motor, stator and rotor technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of difficulty in ensuring the pressing force and tooth expansion requirements at the same time, affecting the overall performance of the motor, and high manufacturing costs. The effect of shortening the length and improving the performance of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

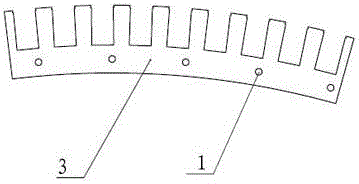

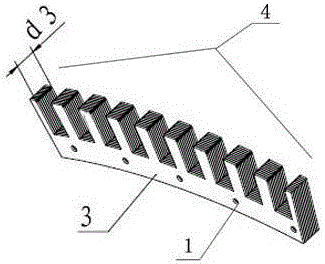

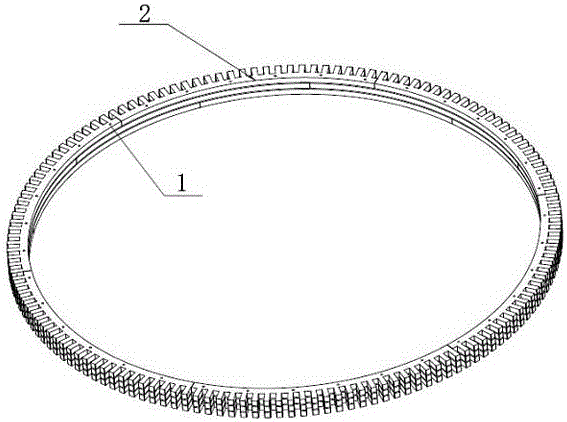

[0011] The stator and rotor anti-tooth expansion iron core of medium and large motors includes a laminated silicon steel sheet body. A connecting hole 1 is opened on the silicon steel sheet body, and a connecting rod is pierced in the connecting hole 1. The silicon steel sheet body is composed of The self-adhesive silicon steel sheet body 2 is composed of a non-self-adhesive silicon steel sheet in the middle, and after the self-adhesive silicon steel sheet body 2 is spliced into a full circular self-adhesive silicon steel sheet layer by the self-adhesive silicon steel sheet group 4, more The layers are stacked with staggered seams, and the self-adhesive silicon steel sheet group 4 is formed by laminating and bonding arc-shaped self-adhesive silicon steel sheet units 3 coated with a self-adhesive coating on the multi-layer surface. The connection holes 1 are opened on each self-adhesive silicon steel sheet unit 3, and the self-adhesive silicon steel sheet groups 4 are laminate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com