Low-voltage wire harness integration device for drive motor of new energy vehicle

A technology for driving motors and integrated devices, applied in electromechanical devices, electrical components, electric components, etc., can solve the problem of motor temperature sensor wiring harness assembly, unresolved wiring and sealing, the accuracy of motor low-voltage wiring harness connection has not been improved, and motor layout space Large demand and other problems, to achieve the effect of reducing intermediate production and assembly links, saving wiring harness layout space, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

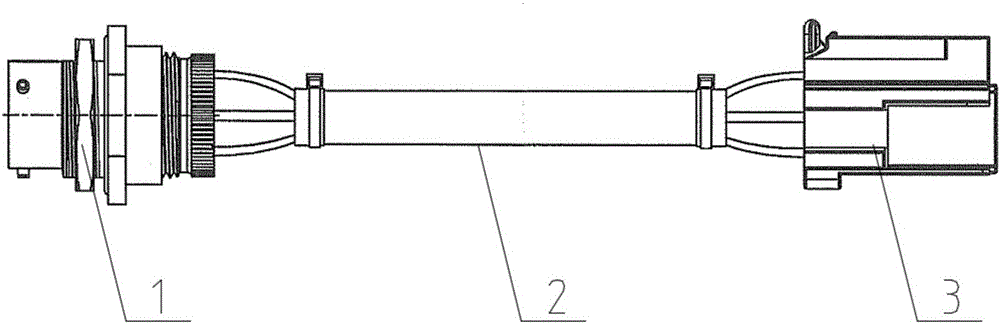

Method used

Image

Examples

Embodiment

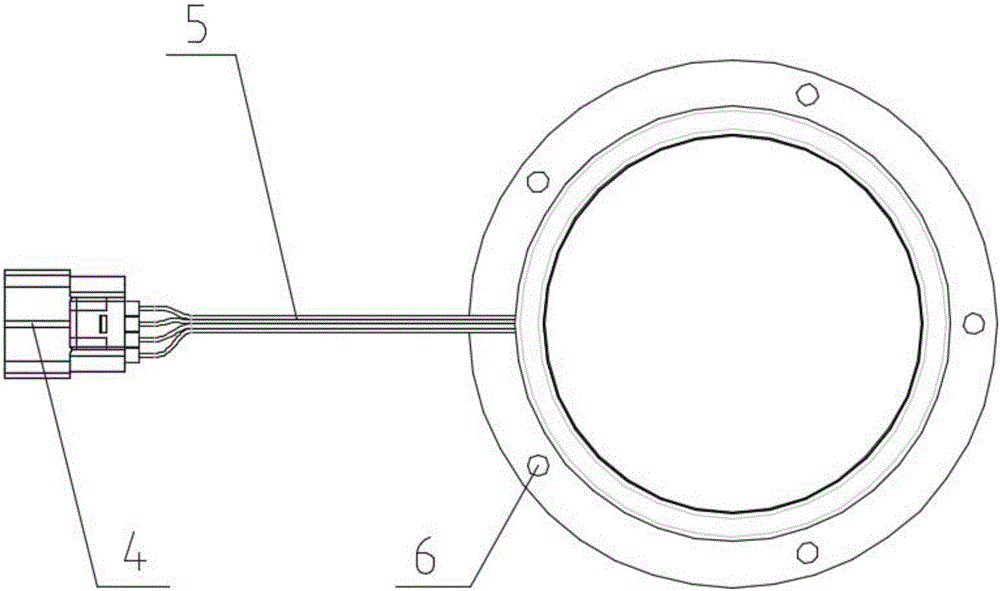

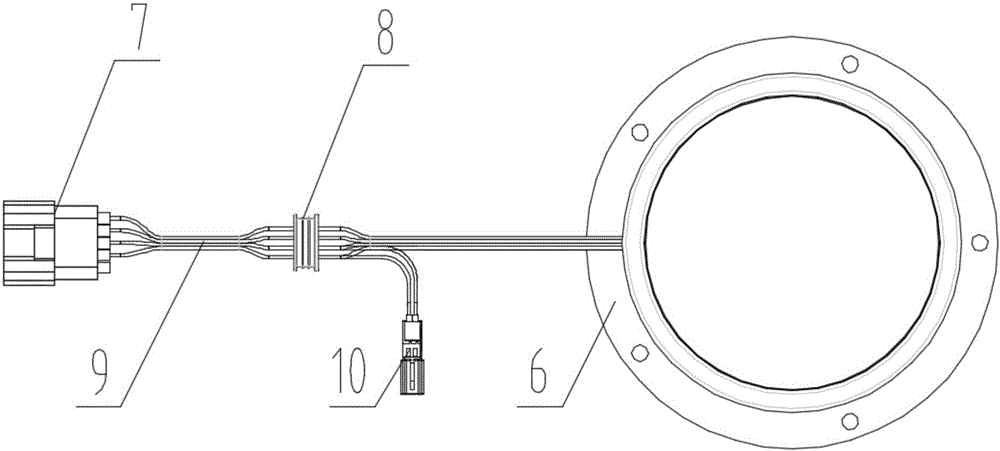

[0023] Such as Figure 4 As shown, the application of the motor low-voltage wire harness integration device 11 on a certain new energy vehicle example motor 12 is as follows: The motor low-voltage wire harness integration device 11 is installed at the rear end of the example motor 12, and passes through the rubber seal block 8 to pass through the motor housing 13. The rubber sealing block 8 is stuck in the sealing groove of the motor housing 13. Through the installation and cooperation of the housing and the end cover, the rubber sealing block 8 is compressed to achieve the cylinder seal of the low-voltage wire harness 9, and the part of the example motor 12 waterproof and dustproof (i.e. IP protection) requirements; one end of the low-voltage wire harness 9 on the motor low-voltage wire harness integration device 11 is directly connected to the resolver stator 6, and the other end is directly connected to the PIN pin connector 7, and the PIN pin connector 7 extends out. Exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com