Radial magnetizing vacuum cleaning motor

A vacuum and clean technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuits, electrical components, etc., can solve problems such as few studies, no consideration at the same time, high cost, etc., to avoid organic pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

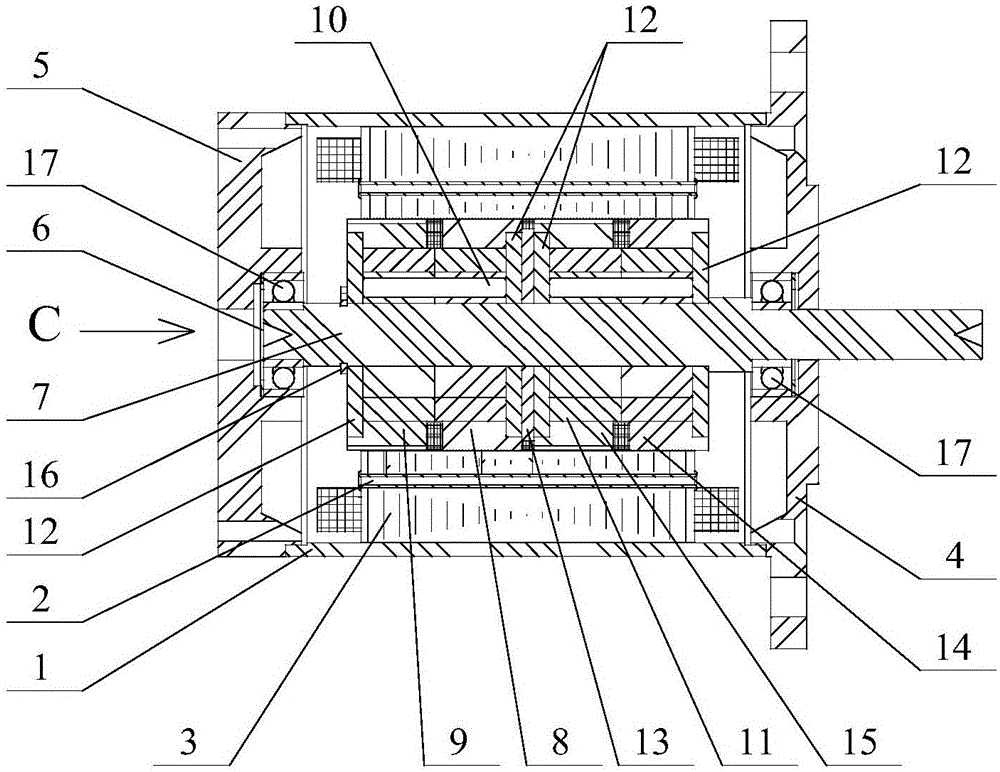

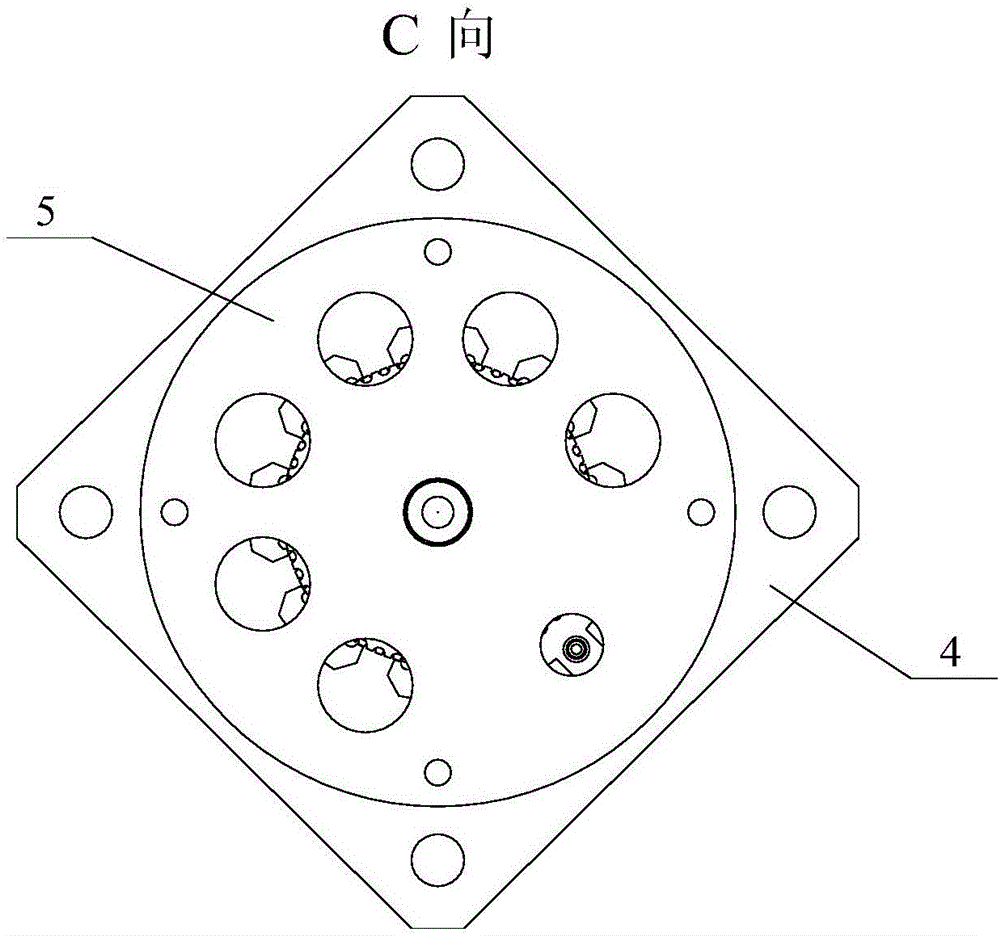

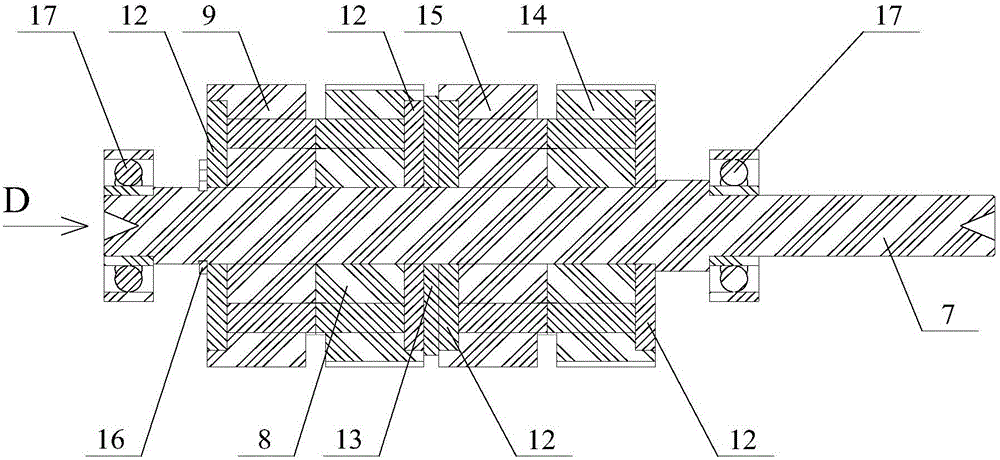

[0035] Such as Figure 1 to Figure 9As shown, a vacuum cleaning motor with radial magnetization involved in this embodiment includes: motor casing 1, stator punching rivets 2, stator punching 3, motor front end cover 4, motor rear end cover 5, bearing Spring pad 6, motor rotor shaft 7, motor rotor yoke three 8, motor rotor yoke four 9, motor rotor yoke positioning pin 10, rotor permanent magnet 11, rotor body retaining ring 12, rotor spacer ring 13, motor rotor yoke one 14, Motor rotor yoke 2 15, rotor shaft circlip 16 and ceramic deep groove ball bearing 17, the motor front end cover 4 is installed on the front end of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com