Compressive sensing-based power grid equipment patrol inspection positioning method

A technology of power grid equipment and compressed sensing, which is applied in the direction of electrical components, network topology, advanced technology, etc., can solve the problems of increasing production costs, labor costs, easy fading of QR codes, and low reliability, so as to promote intelligent patrol inspection, The effect of improving work quality and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

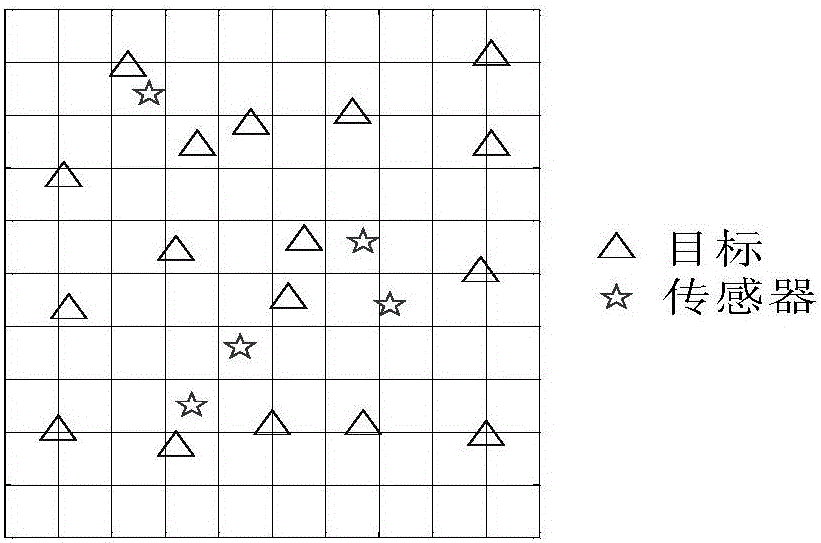

[0095] First, the present invention describes the simulation parameters, uses Matlab to carry out simulation verification, and the compressed sensing reconstruction algorithm is the BP algorithm. The model positioning area is set as a square area of 50m×50m, divided into 196 grids of 14×14. The value of the sensor number M is 49, and the maximum number of iterations is 6. Signal strength-distance model parameters: P 0 =-40dBm, n p = 2,D 0 =1.

[0096] The target is at the center of the grid:

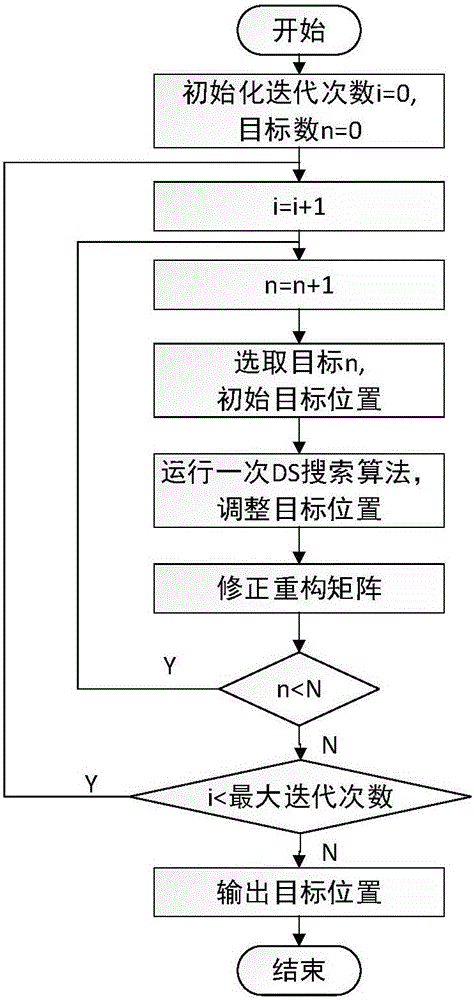

[0097] Place the target at the center of the grid at different positions, and use the compressed sensing positioning algorithm to calculate the maximum x of the reconstructed X under different signal-to-noise ratios n The grid value corresponding to the component, that is, the specific position of the target. Figure 4 The positioning results of the system under three conditions of no noise, SNR=5dB and SNR=20dB are given with the number of targets being 15. It can be seen from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com