Polymer electrolyte membrane, membrane electrode assembly comprising polymer electrolyte membrane, and fuel cell comprising membrane electrode assembly

A technology of electrolyte membrane and polymer, applied in fuel cells, composite electrolytes, power system fuel cells, etc., to achieve excellent durability and high ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

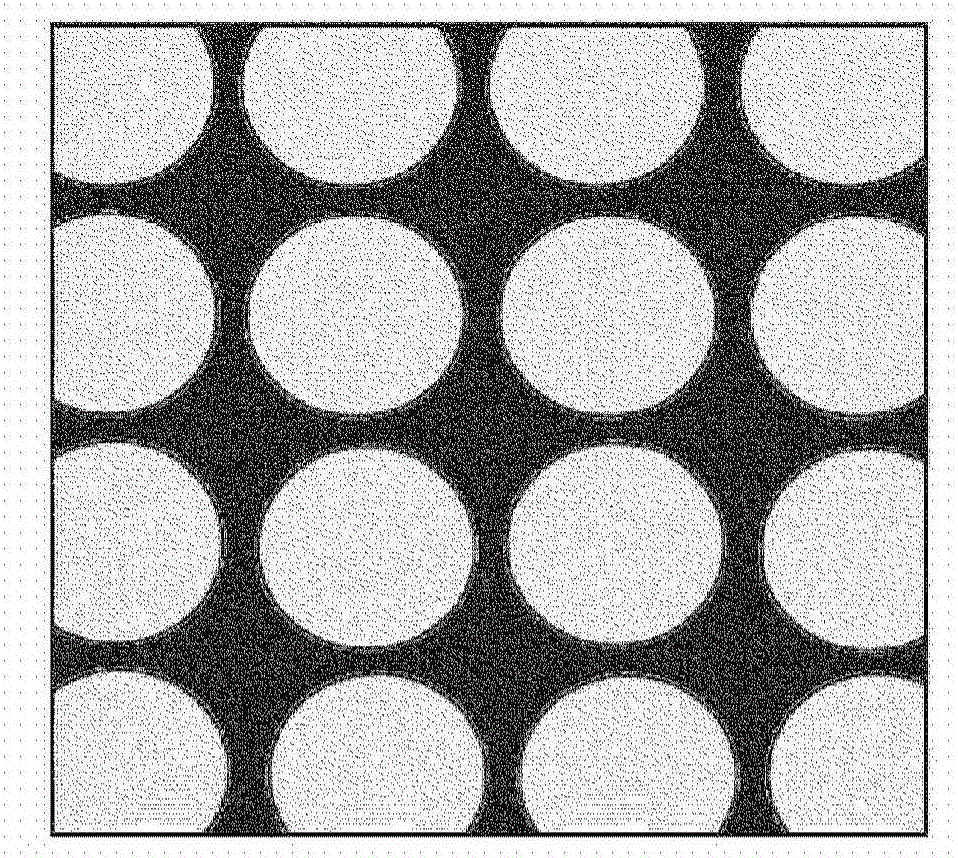

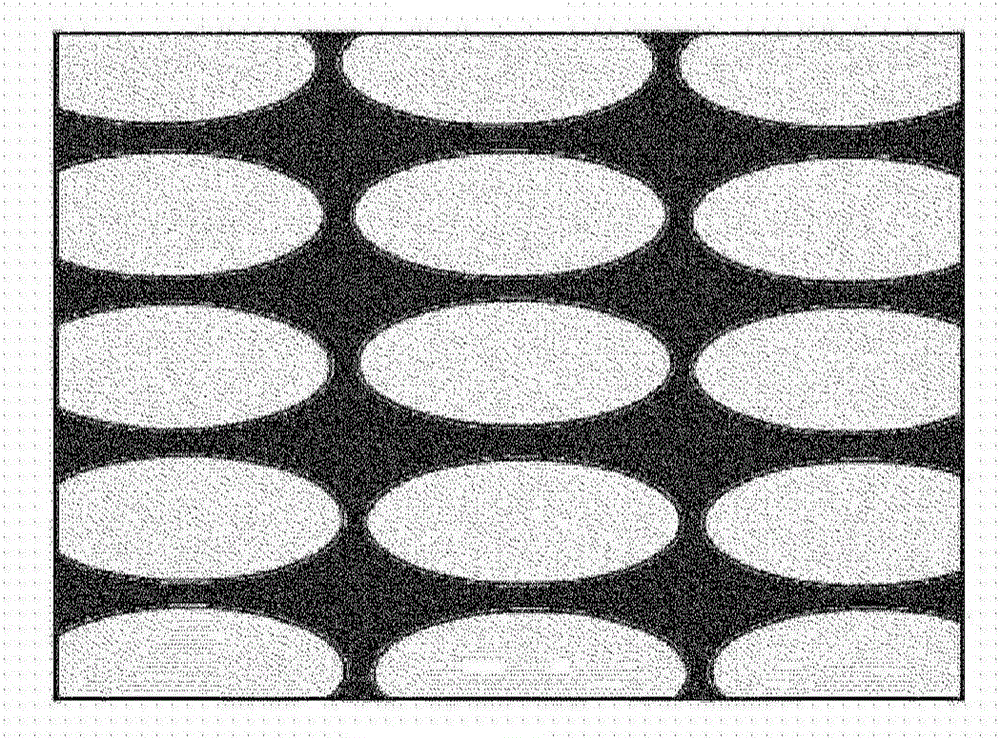

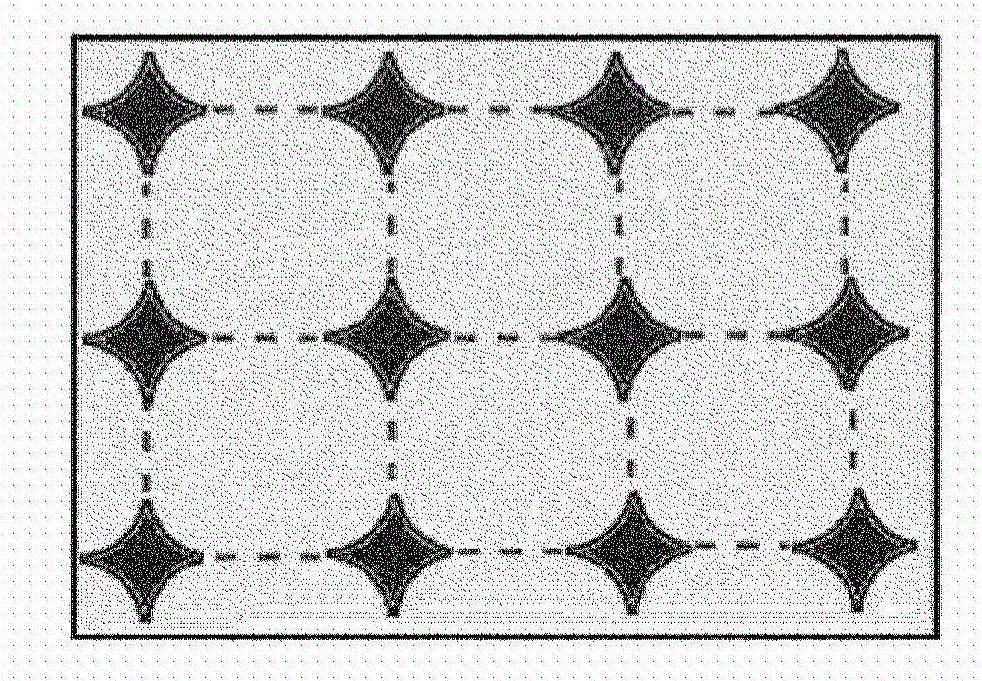

[0154] The impregnation solution was prepared by dissolving 7% by weight of a hydrocarbon-based polymer with an ion exchange capacity (IEC) of 2.16 meq / g in dimethylsulfoxide (DMSO). A support having a thickness of about 5 μm, a porosity of about 80%, and a three-dimensional network structure in which two or more units are regularly distributed is immersed in the impregnating solution. Thereafter, the resultant was dried in an oven at 80° C. for 24 hours to prepare a mixed layer. A solution prepared by dissolving 7% by weight of a hydrocarbon-based polymer having an ion exchange capacity (IEC) of 1.81 meq / g in dimethylsulfoxide (DMSO) was applied on the upper and lower surfaces of the mixed layer , and the resultant was dried in an oven at 80 °C for 24 h to prepare a pure layer. The prepared polymer electrolyte membrane was acid-treated with 10% sulfuric acid at 80° C. for 24 hours, washed with distilled water 4 or more times, and dried at 80° C. to prepare a polymer electrol...

Embodiment 2

[0156] A polymer electrolyte membrane was prepared in the same manner as in Example 1, except that the ion exchange capacity (IEC) of the hydrocarbon-based polymer contained in the impregnation solution was 1.81 meq / g, and a pure layer was not additionally formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com