Simple device for photocatalytically treating organic waste gases

A technology of organic waste gas and photocatalysis, applied in the direction of gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of poor adsorption performance of organic waste gas, and achieve the effect of convenient processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

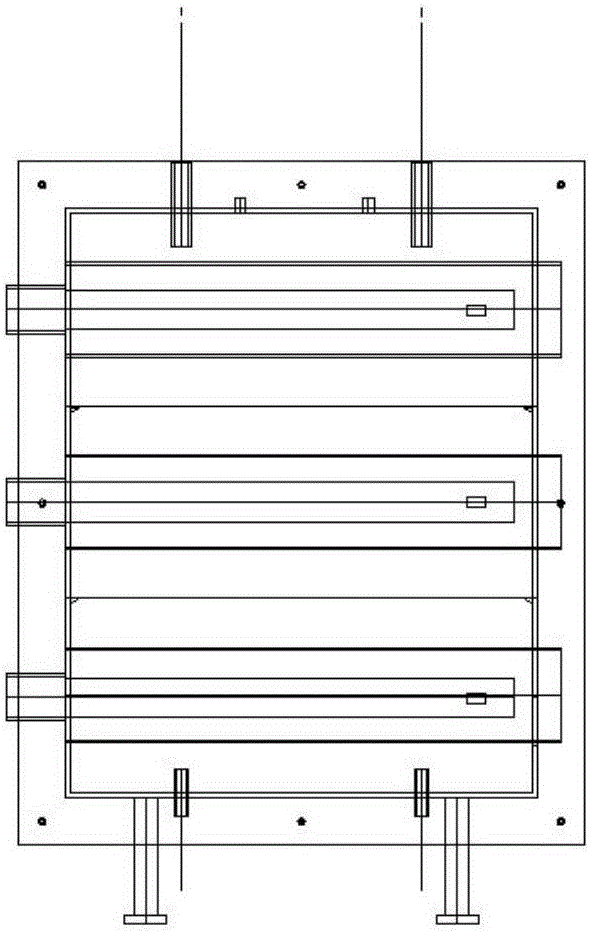

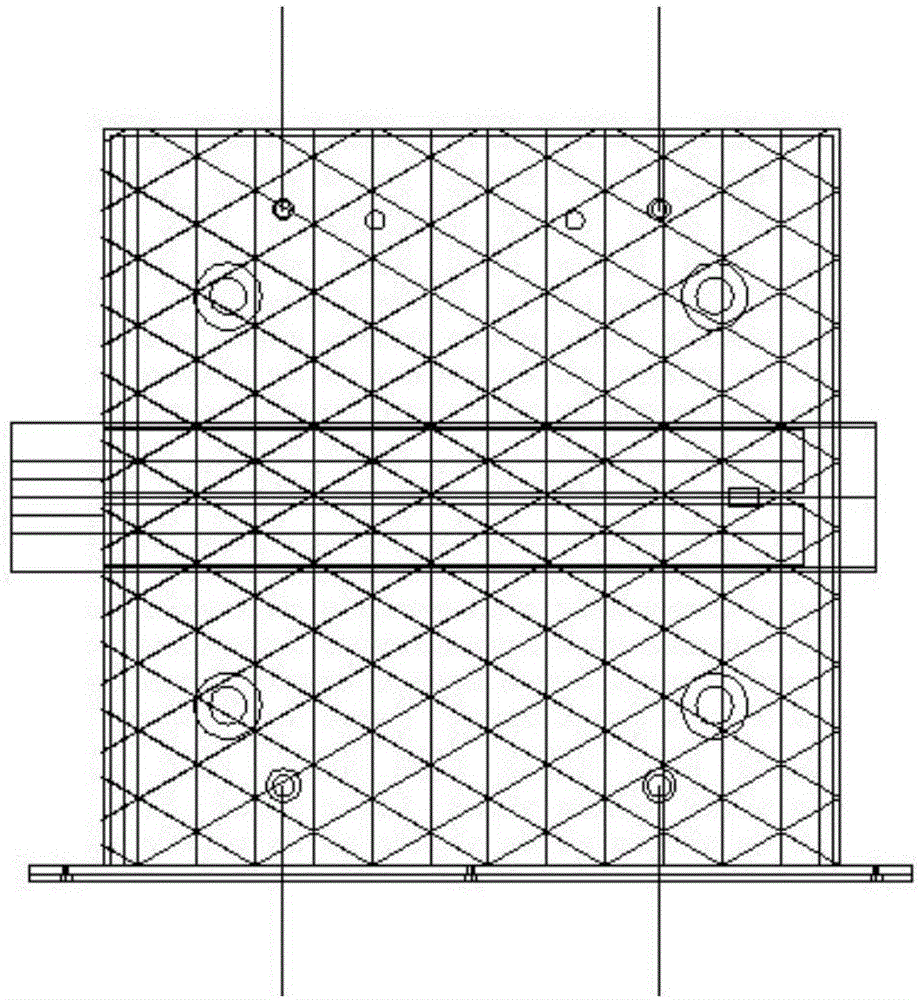

[0042] Refer to attached Figure 4 , 5 , a simple device for photocatalytic treatment of organic waste gas, the device is mainly composed of air outlet 1, hollow quartz glass sleeve 2, ultraviolet lamp 3, movable cover plate 4, support feet 5, organic waste gas inlet 6, slot 7, box body 8. The fixed bed type load is composed of TiO2 foam nickel mesh 9 and the temperature and humidity meter installation port 10. The box body 8 is divided into three layers, and the adjacent two layers are supported by the slot 7 provided on the inner wall of the box (not shown) to support the fixed bed type load. The TiO2 foamed nickel mesh is divided into 9 parts; the left and right sides of the box body 8 have holes crossing to install the hollow quartz glass casing 2, and the ultraviolet lamp tube 3 is placed in the hollow quartz glass casing 2. The rear side of the box body 8 is a detachable cover plate 4, and an elastic gasket (not shown) is arranged between the cover plate 4 and the box b...

example 2

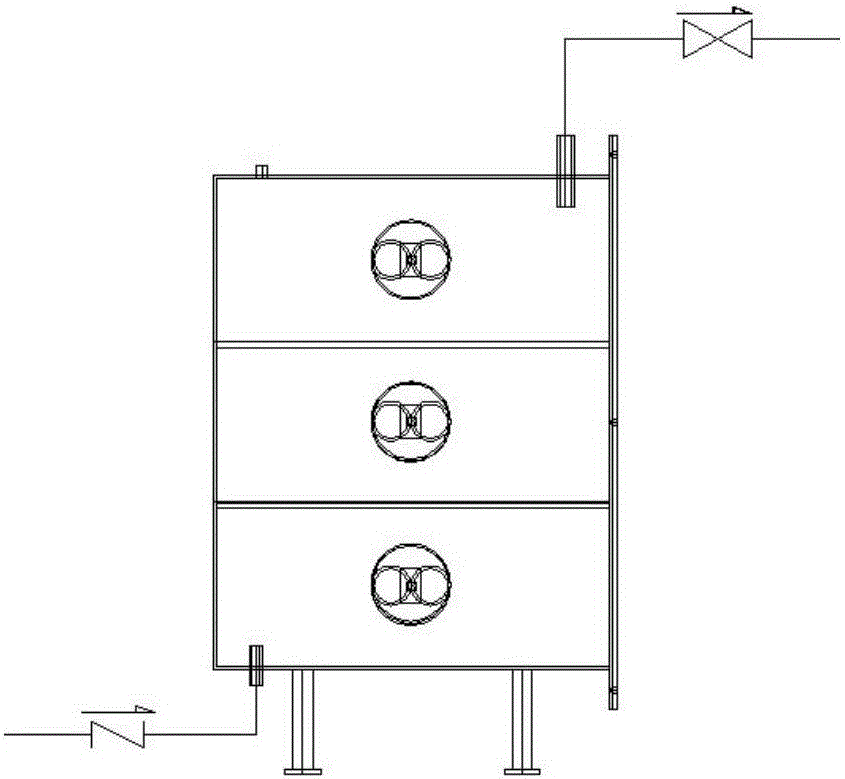

[0046] The present invention also provides an organic waste gas treatment system, which includes a plurality of the above-mentioned simple devices for photocatalytic treatment of organic waste gas, and also includes a control module (not shown) for controlling the operation of the simple device for photocatalytic treatment of organic waste gas; Simple devices for treating organic waste gas are connected in series or in parallel. see Figure 6 , is an organic waste gas treatment system using two simple devices for photocatalytic treatment of organic waste gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dominant wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com