A kind of high temperature resistant methanation catalyst and preparation method thereof

A methanation catalyst and high temperature resistant technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. Carbon deposition ability, high specific surface area, and the effect of preventing high temperature sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

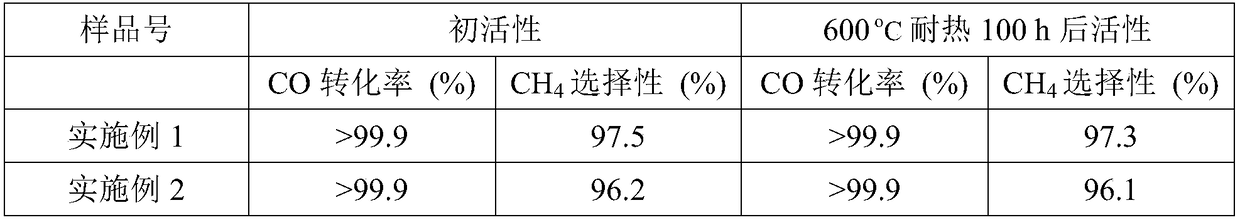

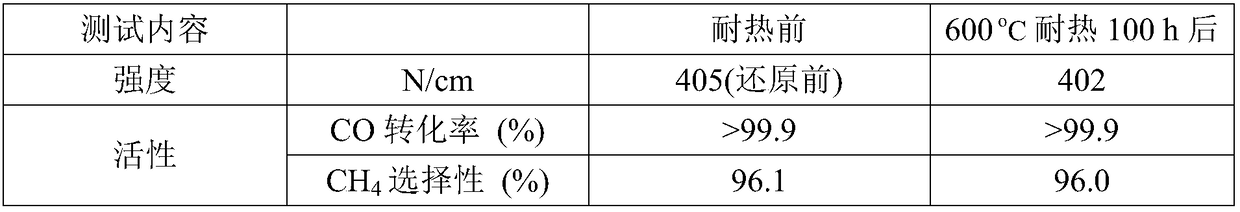

Examples

Embodiment 1

[0024] Prepare the ethanol solution of the required raw materials: dissolve 86.7g nickel nitrate, 172.9g aluminum nitrate, 6.4g tetramethoxysilane, 4.0g lanthanum nitrate, 16.0g magnesium nitrate, 10.5g calcium nitrate in 1300mL of ethanol, and record as solution I;

[0025] To prepare an ethanolic solution of oxalic acid: dissolve 101.5 g of oxalic acid and 30.0 mL of ethylene glycol in 1300 mL of ethanol, and denote it as solution II;

[0026] The solution II was slowly added dropwise to the solution I under stirring at room temperature, and the addition was completed for 5 h; the solvent ethanol was evaporated and removed at 80 °C for 5 h to obtain a uniform and transparent sol, and dried at 150 °C to obtain a dry gel;

[0027] The obtained xerogel was soaked in 500 mL of deionized water, filtered, dried at 80 °C for 5 h, and the extruded material passed through a 20-mesh sieve; after calcined at 450 °C for 5 h and then lowered to room temperature, mixed with 5% graphite fo...

Embodiment 2

[0029] Prepare the ethanol solution of the required raw materials: dissolve 74.3g nickel nitrate, 172.9g aluminum nitrate, 7.6g tetramethoxysilane, 6.7g lanthanum nitrate, 19.3g magnesium nitrate, 12.6g calcium nitrate in 1300mL of ethanol, and record as solution I;

[0030] To prepare the ethanolic solution of oxalic acid: dissolve 103.7 g of oxalic acid and 15.0 mL of polyethylene glycol 400 in 1300 mL of ethanol, and record it as solution II;

[0031] The solution II was slowly added dropwise to the solution I under stirring at room temperature, and the addition was completed for 5 h; the solvent ethanol was evaporated and removed at 80 °C for 5 h to obtain a uniform and transparent sol, and dried at 150 °C to obtain a dry gel;

[0032] The obtained xerogel was soaked in 500 mL of deionized water, filtered, dried at 80 °C for 5 h, and the extruded material passed through a 20-mesh sieve; after calcined at 450 °C for 5 h and then lowered to room temperature, mixed with 5% gr...

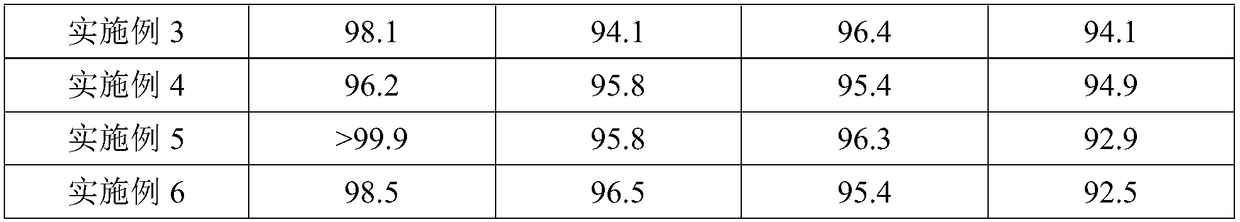

Embodiment 3

[0034] Prepare the ethanol solution of the required raw materials: dissolve 61.9g of nickel nitrate, 183.9g of aluminum nitrate, 12.6g of tetramethoxysilane, 6.7g of lanthanum nitrate, and 32.1g of magnesium nitrate in 1300mL of ethanol, and denote it as solution I;

[0035] To prepare the ethanolic solution of oxalic acid: dissolve 101.5 g of oxalic acid and 15.0 mL of polyethylene glycol 400 in 1300 mL of ethanol, and record it as solution II;

[0036] The solution II was slowly added dropwise to the solution I under stirring at room temperature, and the addition was completed for 5 h; the solvent ethanol was evaporated and removed at 80 °C for 5 h to obtain a uniform and transparent sol, and dried at 150 °C to obtain a dry gel;

[0037] The obtained xerogel was soaked in 500 mL of deionized water, filtered, dried at 80 °C for 5 h, and the extruded material passed through a 20-mesh sieve; after calcined at 550 °C for 5 h and then lowered to room temperature, mixed with 5% gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com