Color sorting machine

A technology of color sorter and conveying mechanism, applied in the field of color sorter, can solve the problems of improper adjustment, need to stop and adjust again, prone to shadows, inconvenient adjustment of material baffles, etc., to achieve good recognition effect and avoid errors , Adjust the effect of convenient and quick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

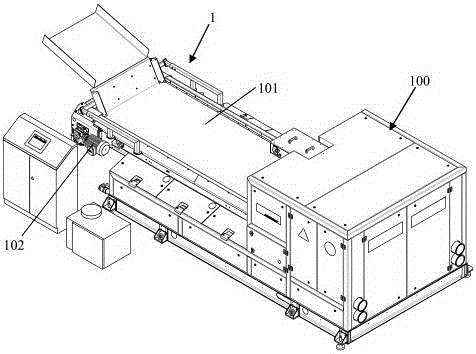

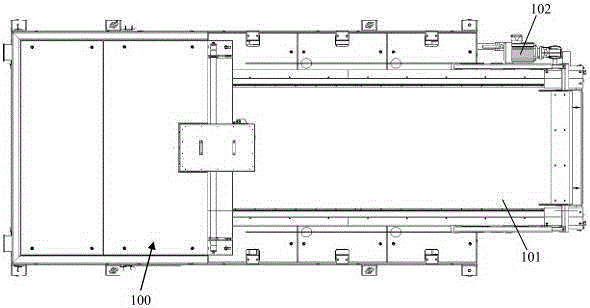

[0025] Such as figure 1 , 2 As shown in .

[0026] The conveying mechanism 1 is arranged on the front side of the optical signal collecting mechanism, and is used for conveying materials to the optical signal collecting mechanism and throwing them up; the conveying mechanism 1 includes a conveyor belt 101 arranged horizontally and drives the conveyor belt 101 to rotate The pulley and the motor 102 that drives the pulley to rotate.

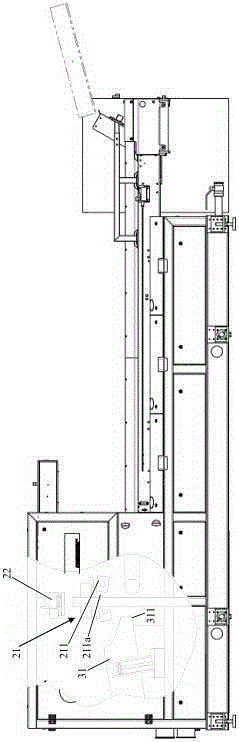

[0027] The optical signal acquisition mechanism includes an illumination system 21 and an image acquisition device 22, the illumination system 21 is located above the track where the material is thrown, and the image acquisition device 22 is located above the illumination system 21; The lighting system 21 includes two strip lamp tubes arranged horizontally and perpendicular to the conveying direction of the conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com