A kind of off-line maintenance method of wear-resistant disc valve

A wear-resistant disc and off-line technology, applied in the field of special valve maintenance, can solve the problems of bad working conditions, cracked stuffing box, valve can not move, etc., and achieve the effect of reducing valve failure rate, saving maintenance cost and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

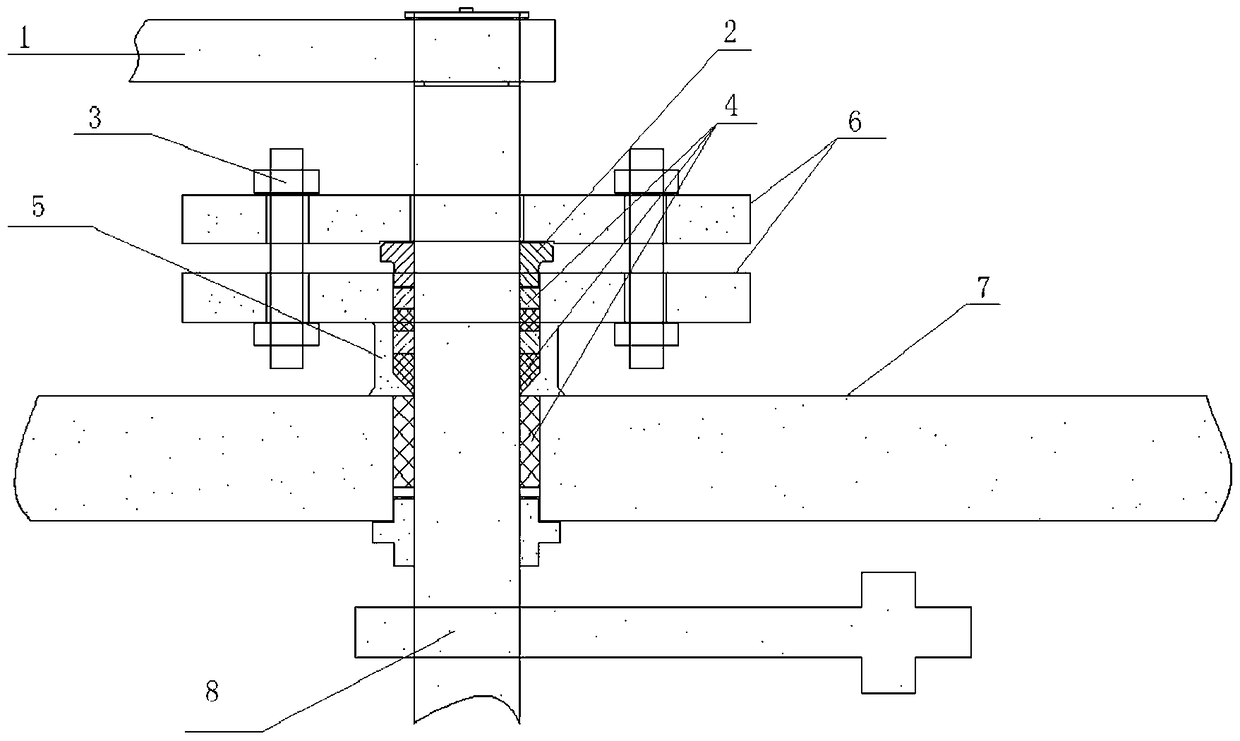

Image

Examples

Embodiment 1

[0027] After the crankshaft is removed, it can be seen that the surface is covered with irregular grooves due to corrosion, accompanied by rust. The maintenance process, the operation steps are as follows:

[0028] 1. Remove the crankshaft, clean it and dry it, and polish the crankshaft with sandpaper to remove all attached rust;

[0029] 2. Use a vernier caliper to measure the outer diameter of the crankshaft and the inner diameter of the packing ring, and record them for future use;

[0030] 3. Use a metal analyzer to determine the material of the crankshaft;

[0031] 4. According to the surface corrosion of the crankshaft (groove depth), use a lathe to plan the corroded surface layer of the crankshaft. The thickness of the planed surface is determined according to the corrosion situation, generally 5~8mm. The length of the planed surface layer is determined according to the corrosion condition and the depth of the stuffing box to ensure that all parts inside the stuffing ...

Embodiment 2

[0048] For stuffing boxes with brittle corrosion cracks, conduct a comprehensive inspection and repair them in a fully compensated manner. The repair steps are as follows:

[0049] 1. Use a carbon planer to remove the welding seam between the stuffing box and the valve body, and take out the stuffing box;

[0050] 2. Clean the stuffing box and remove the debris inside and outside the stuffing box;

[0051] 3. Use a vernier caliper to measure the inner diameter, outer diameter and length of the stuffing box;

[0052] 4. Use a metal analyzer to check the stuffing box material;

[0053] 5. According to the material inspection results, use metal rods of the same material, and the diameter of the rods should exceed the outer diameter of the original stuffing box by 5~8mm. You can also choose a thicker bar according to your needs, so that the wall thickness of the stuffing box after processing is thicker;

[0054] 6. After the bar material is obtained, use a milling machine to d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com