Brake energy recovery and release device

A technology of braking energy recovery and release device, applied in the directions of brakes, braking components, transportation and packaging, can solve the problems of extra work, loss, complex structure, etc., and achieve the effects of simple control, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

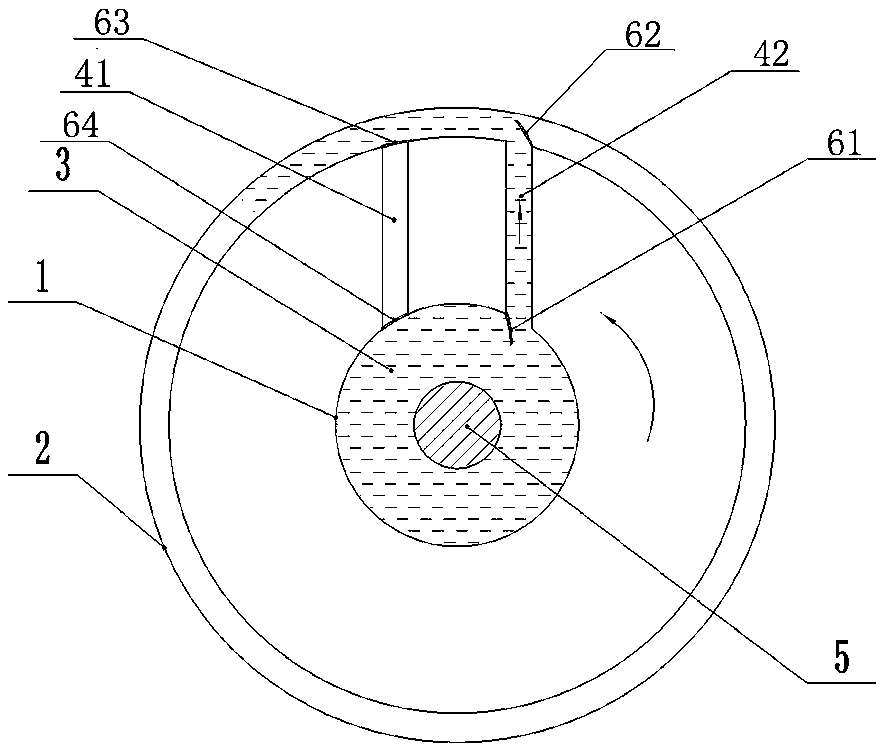

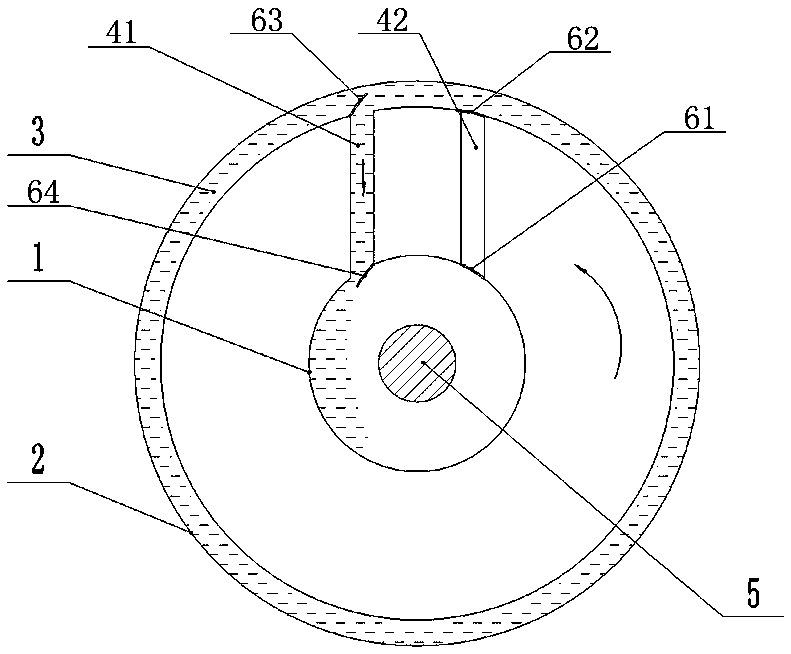

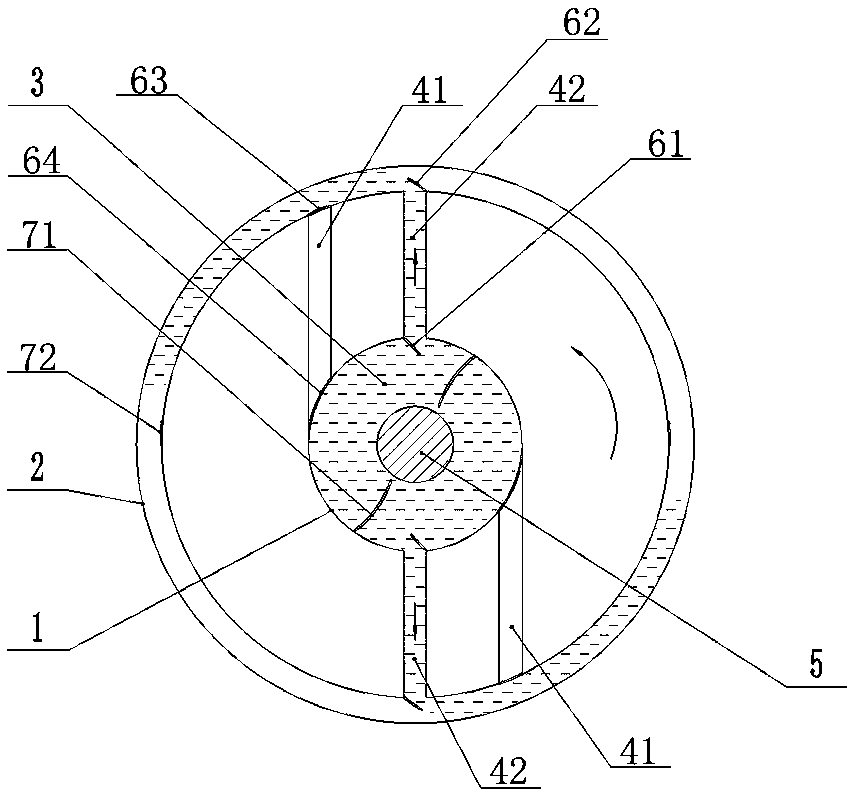

[0024] Figure 1-Figure 2 The brake energy recovery and release device shown includes an inner ring 1 and an outer ring 2 both having cavities, and the diameter of the inner ring 1 is smaller than that of the outer ring 2, and there is a liquid fluid 3 in the cavity of the inner ring 1 and the outer ring 2 There is a guide channel through which the liquid fluid 3 passes between the inner ring 1 and the outer ring 2, and the guide channel includes a return channel 41 and an outflow channel 42, and the liquid fluid flows inward from the outer ring 2 in the return channel 41 The ring 1 flows, and the liquid fluid flows from the inner ring 1 to the outer ring 2 in the outflow channel 42, and at least one of the inner ring 1, the outer ring 2 and the guide channel is connected with the rotating shaft 5 ( Figure 6 ), a valve is provided at the connection between the guide channel and the inner ring 1 and the outer ring 2.

[0025] The interior of the inner ring 1, the outer ring 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com