Connection structure for automobile parts and production method of connection structure

A technology of auto parts and connection structure, which is applied in the field of auto parts, can solve the problems that cannot meet the requirements of objective application, surface delamination and shear damage, poor connection strength, etc., and achieve the elimination of surface delamination and shear damage, Effects of improving connection efficiency and improving connection durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

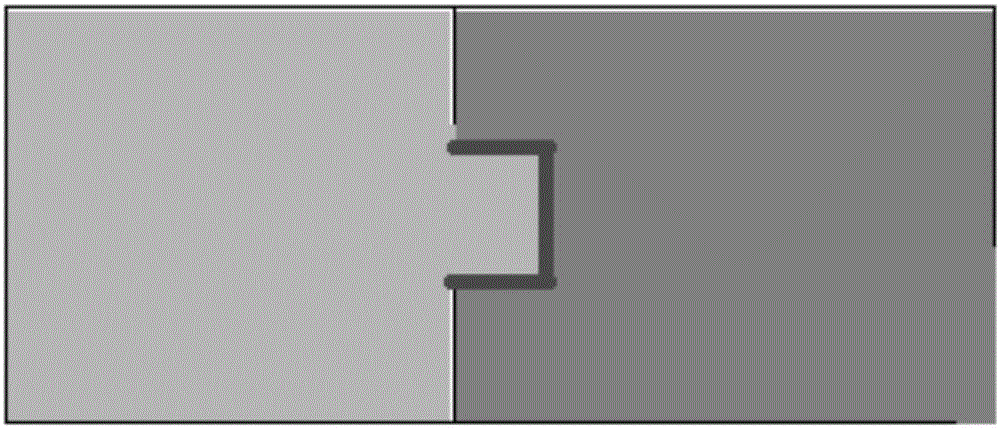

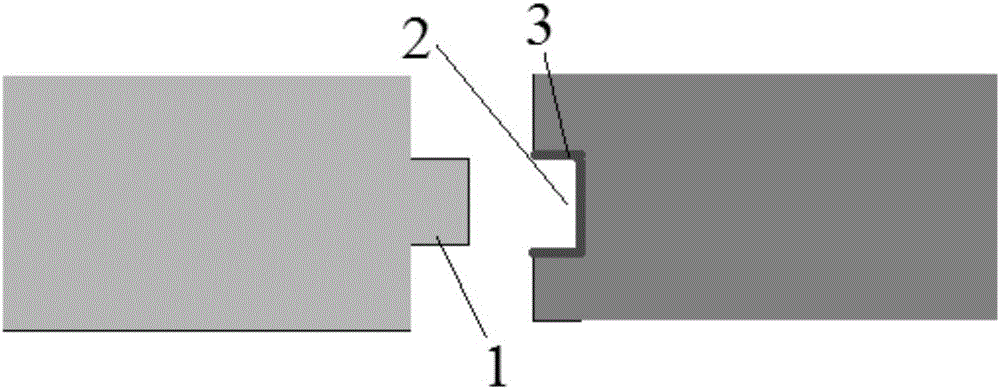

[0029] Such as figure 1 with figure 2 As shown, the present invention provides a connection structure for automobile parts, including a first connecting piece and a second connecting piece that is glued to the first connecting piece, and the first connecting piece and the second connecting piece are made of carbon fiber composite materials . The first connecting part has a protruding tongue and the second connecting part has a groove into which the tongue is inserted. Different from ordinary plate bonding, tongue and groove bonding is suitable for the connection between thick carbon fiber plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com