EVA hot-melt adhesive for kitchenware

A technology of hot melt adhesives and kitchen utensils, which is applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., and can solve problems such as limited application, intolerance to grease, and reduced bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0048] As an embodiment of the present invention, the VA content in the EVA resin is 20-32% by weight.

[0049] The melt index of the EVA resin is 15-400 g / 10min.

[0050] In EVA hot-melt adhesives, the lower the VA content, the higher the crystallinity increases the hardness; the higher the VA content, the lower the crystallinity and the greater the elasticity. The choice of EVA melt index is also very important. The smaller the melt index, the poorer the fluidity, the higher the strength, the higher the melting temperature, and the poorer the wetting and permeability of the adherend; better, but lower bond strength.

[0051] As a most preferred embodiment of the present invention, the VA content in the EVA resin is 28% by weight.

[0052] Vinylbenzene fused heterocyclic mixture

[0053] In the present invention, the vinylbenzene fused heterocyclic mixture includes sulfonated vinylbenzene fused heterocyclic compounds and unsulfonated vinylbenzene fused heterocyclic compoun...

Embodiment approach 1

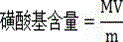

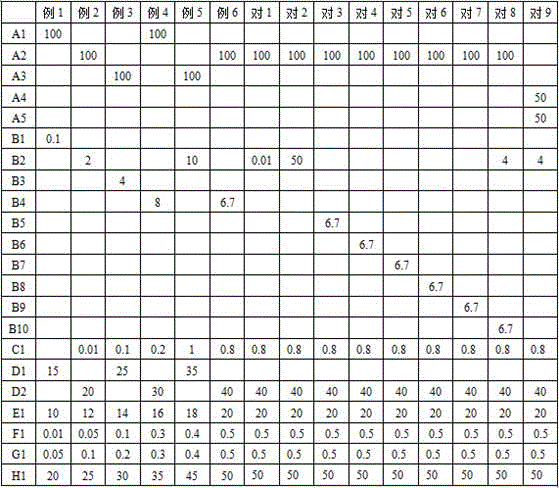

[0121] Embodiment 1: An EVA hot melt adhesive for kitchen utensils, in parts by weight, its preparation raw materials at least include:

[0122] 100 parts of EVA resin;

[0123] Vinylbenzene condensed heterocyclic mixture 0.1-10 parts;

[0124] 15-40 parts of tackifier;

[0125] Viscosity regulator 10-20 parts;

[0126] Antioxidant 0.01-0.5 parts;

[0127] Initiator 0.05-0.5 part;

[0128] Filling 20-50 parts;

[0129] Wherein, the vinylbenzene fused heterocyclic mixture includes sulfonated vinylbenzene fused heterocyclic compounds and unsulfonated vinylbenzene fused heterocyclic compounds, and the vinylbenzene fused heterocyclic compounds are selected from: 2-ethylene Base-1-benzofuran or 2-vinyl-1-benzothiophene.

Embodiment approach 2

[0130] Embodiment 2: Same as Embodiment 1, the difference is that the molar ratio of the sulfonated vinylbenzene fused heterocyclic compound to the non-sulfonated vinylbenzene condensed heterocyclic compound is 1: (2-10).

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com