A kind of terbium-germanium-bismuth material, preparation method and application thereof

A raw material, cubic crystal technology, applied in the field of terbium-germanium-bismuth material preparation, can solve the problems of commercial application limitation, weakening magnetocaloric performance, etc., and achieve the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

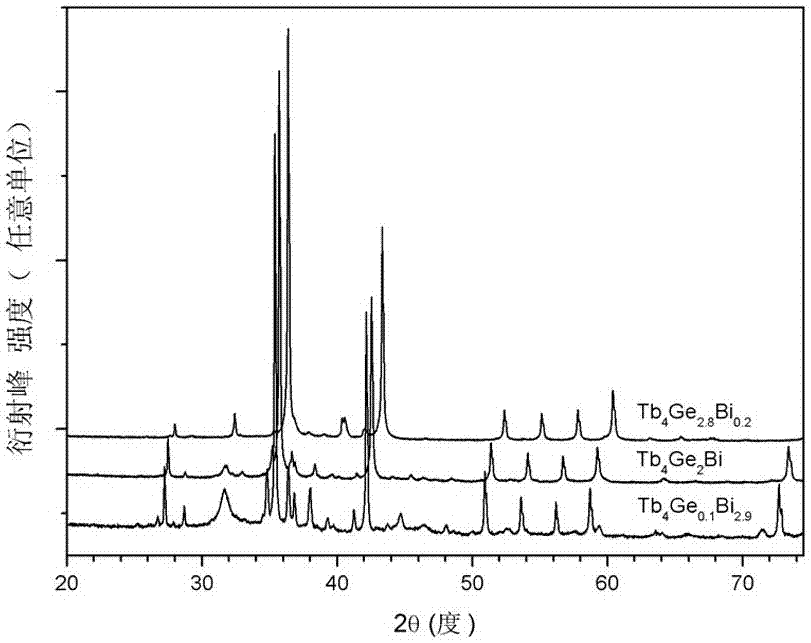

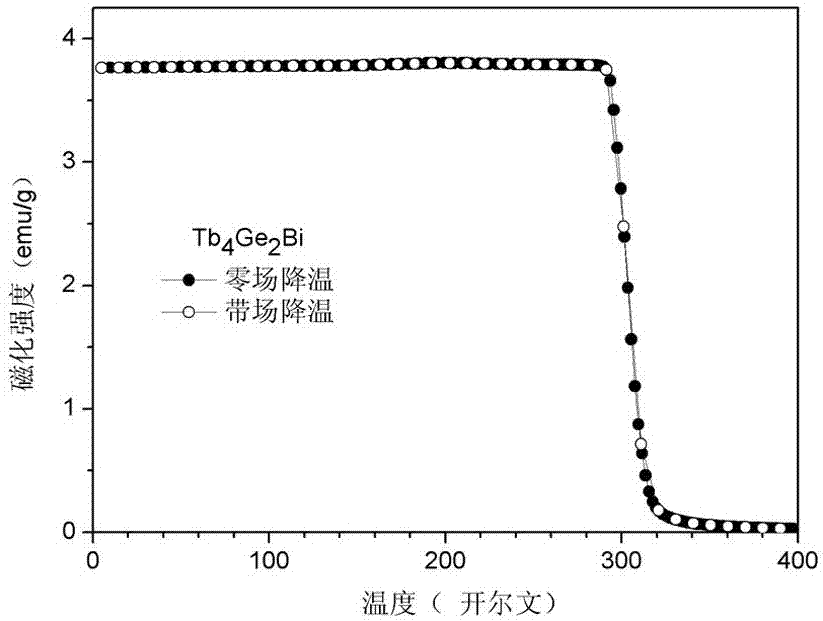

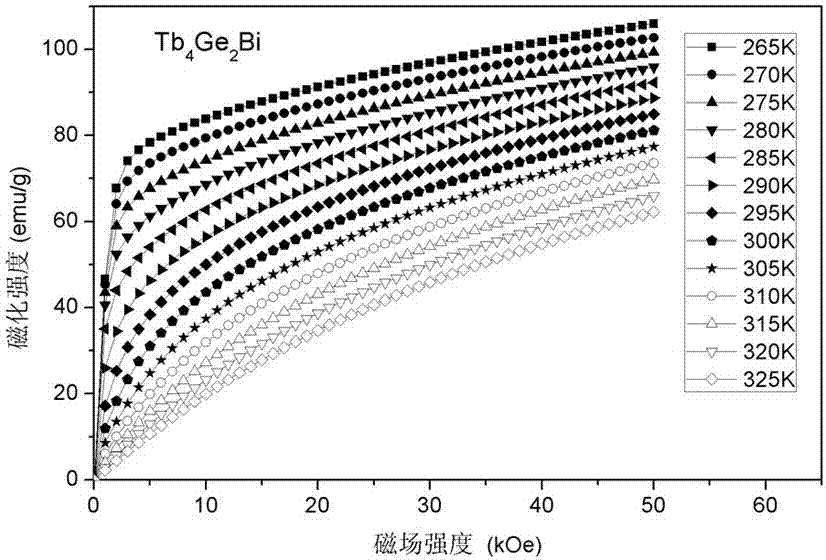

[0029] This embodiment prepares material Tb 4 Ge 2 Bi and determine its performance.

[0030] 1. Tb 4 Ge 2The preparation of Bi specifically comprises the following steps:

[0031] Step 1: Press Tb 4 Ge 2 Bi chemical formula (that is, atomic ratio) is weighed, and the commercially available rare earth metal Tb, semiconductor Ge, and metal Bi raw materials with a purity higher than 99.9% are mixed, and Bi is added in excess of 5% (atomic percentage);

[0032] Step 2: Put the raw materials configured in step 1 into the electric arc furnace or induction heating furnace to vacuumize, when the vacuum degree reaches 5×10 -2 Pa~1×10 -3 Pa, after cleaning with high-purity argon with a purity of 99.999% for 1 or 2 times, vacuum again to 5×10 - 2 Pa~1×10 -3 Pa, filled with high-purity argon protection, the pressure in the furnace chamber is 1 atmosphere, repeated turning and melting for 3 to 5 times, the melting temperature is between 1200 ° C and 1700 ° C, and the melting tim...

Embodiment 2

[0047] This embodiment prepares material Tb 4 Ge 0.1 Bi 2.9 , and measure its performance.

[0048] 1. Tb 4 Ge 0.1 Bi 2.9 The preparation specifically comprises the following steps:

[0049] Step 1: Press Tb 4 Ge 0.1 Bi 2.9 Chemical formula (that is, atomic ratio) weighing, mixing commercially available Tb, Ge, and Bi raw materials with a purity higher than 99.9%, where Bi is added in excess of 15% (atomic percentage);

[0050] Step 2: Put the raw materials configured in step 1 into the electric arc furnace or induction heating furnace to vacuumize, when the vacuum degree reaches 5×10 -2 Pa~1×10 -3 Pa, after cleaning with high-purity argon with a purity of 99.999% for 1 or 2 times, vacuum again to 5×10 - 2 Pa~1×10 -3 Pa, filled with high-purity argon protection, the pressure in the furnace chamber is 1 atmosphere, repeated turning and melting for 3 to 5 times, the melting temperature is between 1200 ° C and 1700 ° C, and the melting time is 30 seconds;

[0051] S...

Embodiment 3

[0060]This embodiment prepares bride price Tb 4 Ge 2.8 Bi 0.2 and measure its performance.

[0061] 1. Tb 4 Ge 2.8 Bi 0.2 The preparation specifically comprises the following steps:

[0062] Step 1: Press Tb 4 Ge 2.8 Bi 0.2 Chemical formula (that is, atomic ratio) weighing, mixing commercially available Tb, Ge, and Bi raw materials with a purity higher than 99.9%, and adding 1% (atomic percentage) of Bi in excess;

[0063] Step 2: Put the raw materials configured in step 1 into the electric arc furnace or induction heating furnace to vacuumize, when the vacuum degree reaches 5×10 -2 Pa~1×10 -3 Pa, after cleaning with high-purity argon with a purity of 99.999% for 1 or 2 times, vacuum again to 5×10 - 2 Pa~1×10 -3 Pa, filled with high-purity argon protection, the pressure in the furnace chamber is 1 atmosphere, repeated turning and melting 3 to 5 times, the melting temperature is between 1200 ° C and 1700 ° C, and the melting time is 80 seconds;

[0064] Step 3: Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com