Single-phase rhodium-based alloy magnetic refrigeration material as well as preparation method and application thereof

A technology of magnetic refrigeration materials and base alloys, which is applied in the fields of magnetic materials, inductor/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems that cannot meet the practical requirements of refrigeration equipment, achieve excellent magnetic refrigeration performance and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

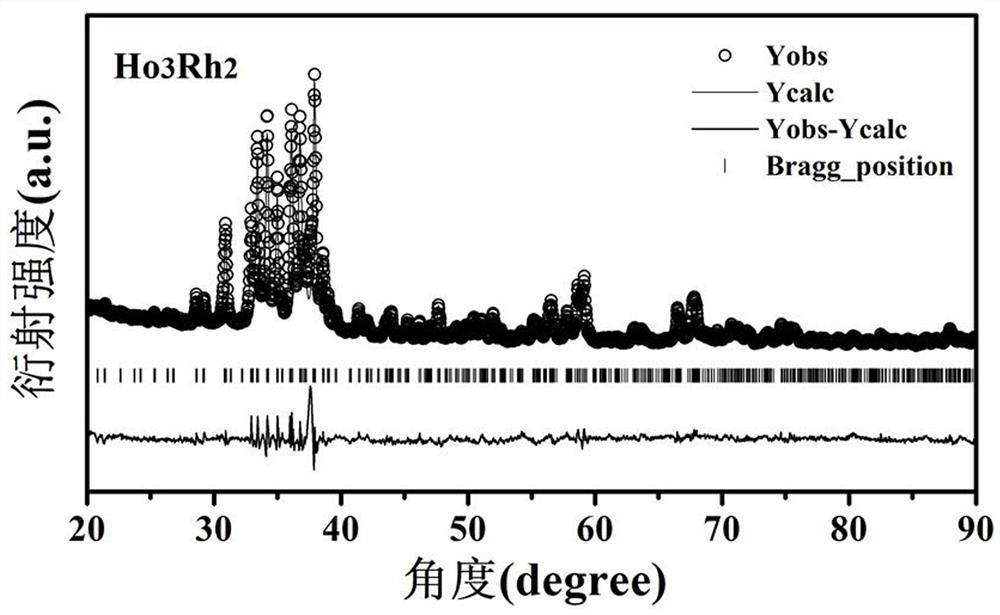

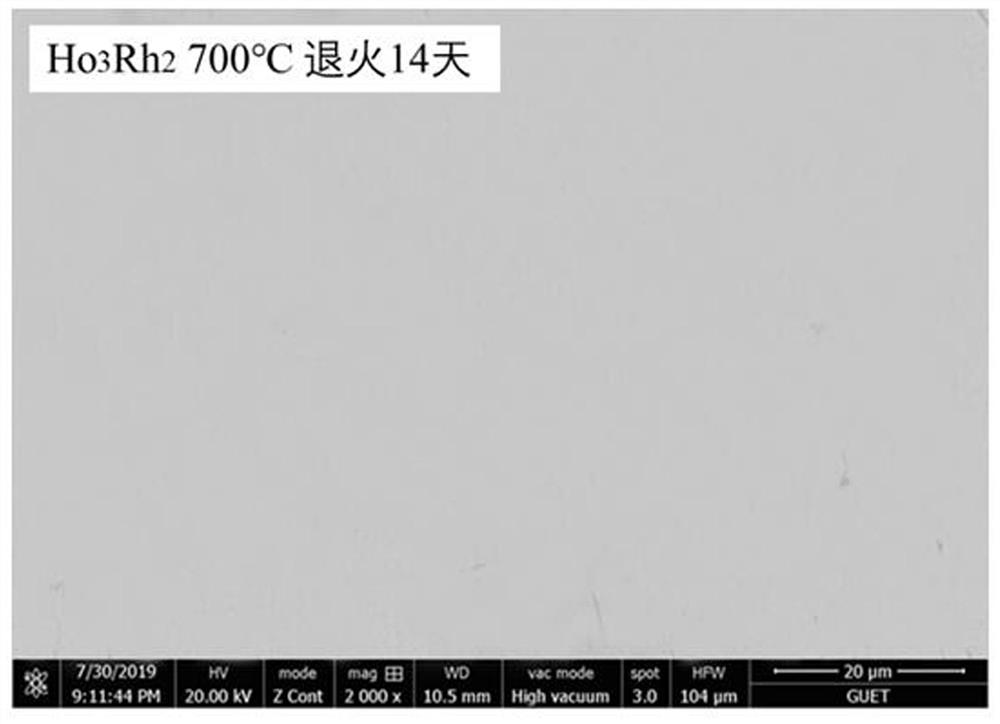

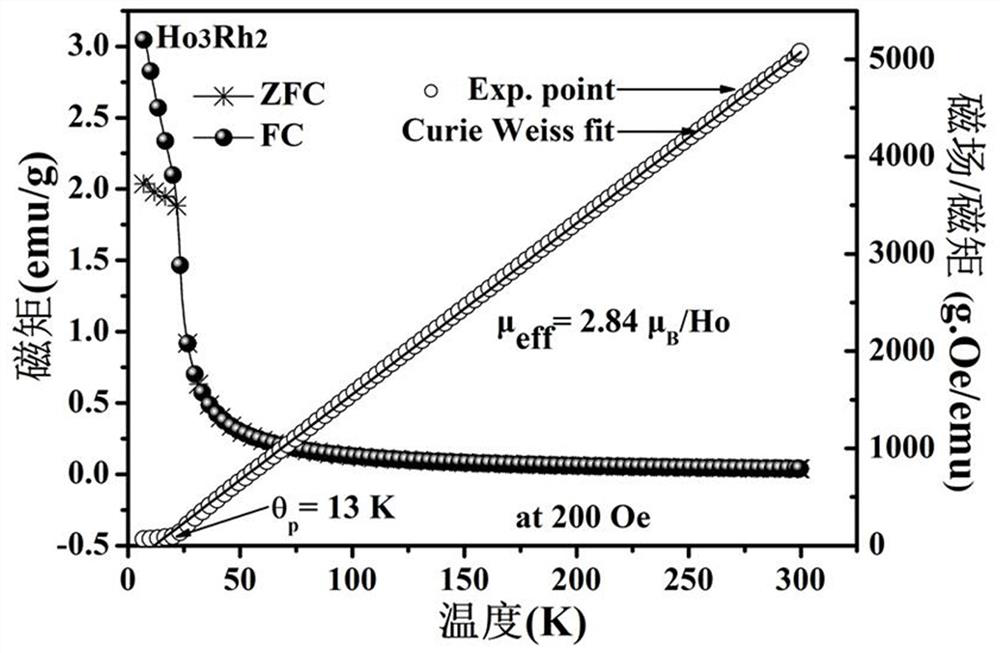

[0049] A single-phase Ho 3 Rh 2 The preparation method of the alloy magnetic refrigeration material, the specific steps are as follows:

[0050] Step 1) Ho 3 Rh 2 Melting of alloy magnetic refrigeration alloy ingots, according to the chemical formula Ho 3 Rh 2 After weighing Ho and Rh raw materials, among them, the amount of Ho added should be added 0.5wt.% on the basis of the theoretical content as compensation, put the prepared raw materials into the electric arc furnace and use two-stage vacuuming with mechanical pump and diffusion pump , when the vacuum reaches 2×10 -3 Pa, after cleaning twice with high-purity argon gas with a purity of 99.99%, repeated flipping and melting three times under the protection of high-purity argon gas at 1 atmospheric pressure, and cooling to room temperature with the furnace after melting to obtain a rhodium-based alloy magnet with uniform composition. refrigeration alloy ingot;

[0051] Step 2) Ho 3 Rh 2 The annealing treatment of a...

Embodiment 2

[0066] a kind of Er 3 Rh 2 The preparation method of the alloy magnetic refrigeration material, the steps not specified in particular are the same as the preparation method described in Example 1, the difference is: the step 1) smelting of the alloy magnetic refrigeration material, specifically according to Er 3 Rh 2 The amount of substance of the chemical formula is 3:2 Weigh Er with 99.99% purity and Rh with 99.999% purity.

[0067] In order to carry out phase identification and structural characterization of the obtained product, Er was determined by X-ray diffractometer. 3 Rh 2 room temperature X-ray diffraction lines. Such as Figure 7 As shown, the refinement results show that the experimental data are in good agreement with the calculated values, Er 3 Rh 2 for Y 3 Rh 2 It is a single-phase compound with tetragonal crystal structure, and its space group is I4 / mcm.

[0068] In order to further prove the phase composition and single-phase property of the obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com