Blowing and atomized oil-spraying intelligent cascading turning type electronic control method for improving embroidery efficiency

A gas atomization and cascading technology, applied in the mechanism of embroidery machines, embroidery machines, textiles and papermaking, etc., can solve problems such as system troubles, achieve the effects of protecting the environment, saving the total cost of equipment, and improving system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

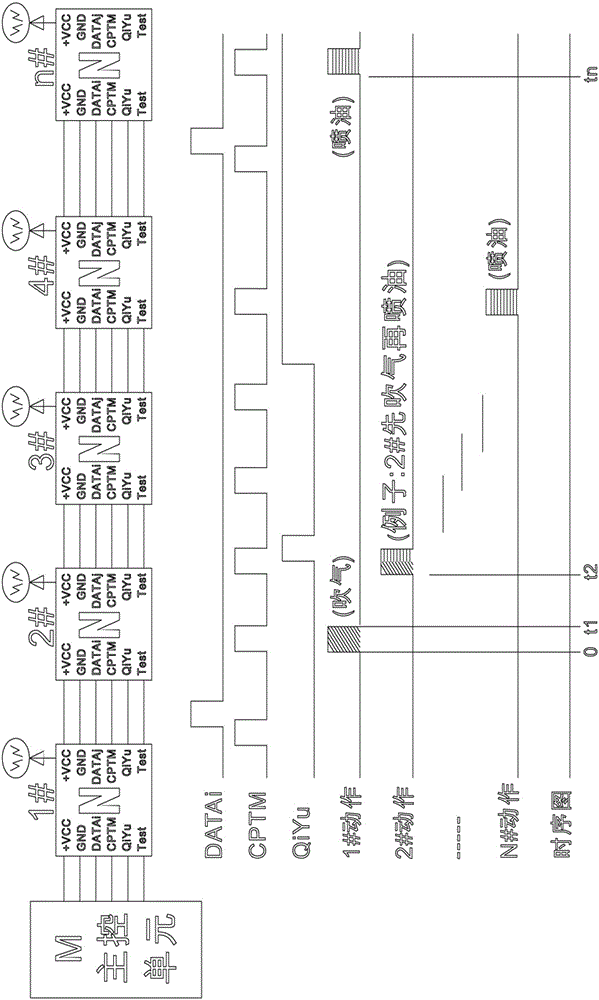

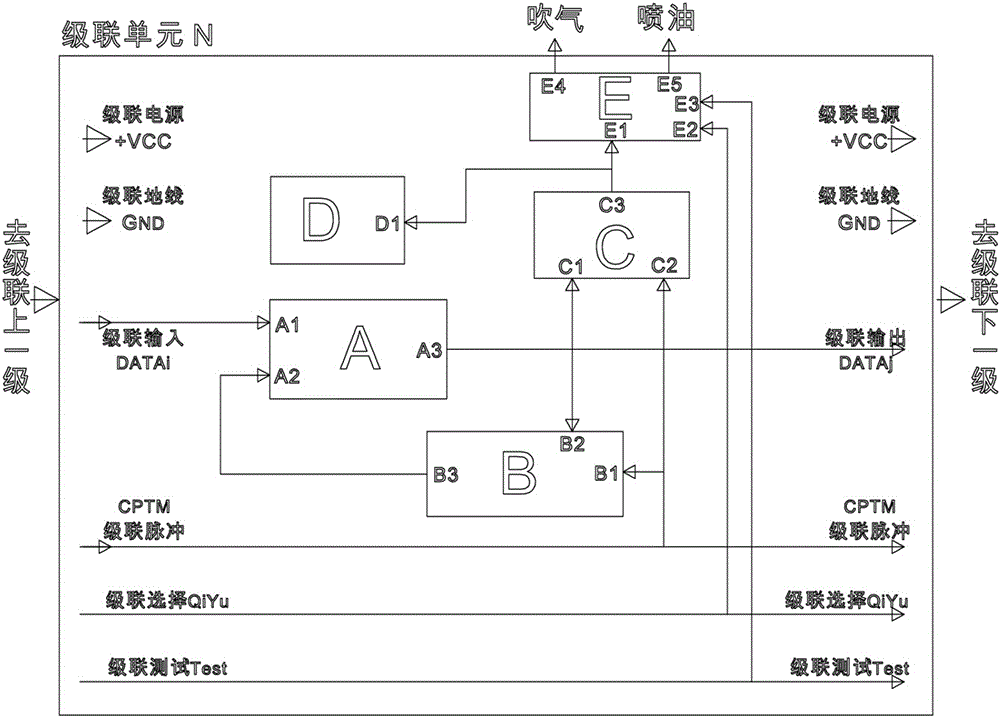

[0028] Such as figure 1 As shown, an intelligent cascaded round-robin electronic control method of air blowing, atomization and fuel injection to improve embroidery efficiency is characterized in that: the main control unit M samples the mechanical operating speeds of multiple cascading units N, and according to the mechanical operating speed Calculate the time interval of blowing or atomizing oil injection lubrication according to the size of the size, and use the calculated time to perform air blowing or atomizing oil injection lubrication on the machinery of the cascade unit N;

[0029] Among them: the main control unit M integrates the algorithm formula of blowing or atomizing oil injection lubrication:

[0030] t n =K*t 1 / ∑ n 2

[0031] Among them, t n is the cycle time of the entire atomization lubrication process;

[0032] K is the required atomization lubrication intensity coefficient and self-adaptive proportional coefficient (after the fuel injection cycle an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com