Paper deacidifying solution and preparation method thereof

A deacidification and paper technology, which is applied in the post-processing of waste paper, etc., can solve the problems of small number of documents and expensive equipment for single batch processing, and achieve surface tension reduction, simple preparation, and low requirements for shape and preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

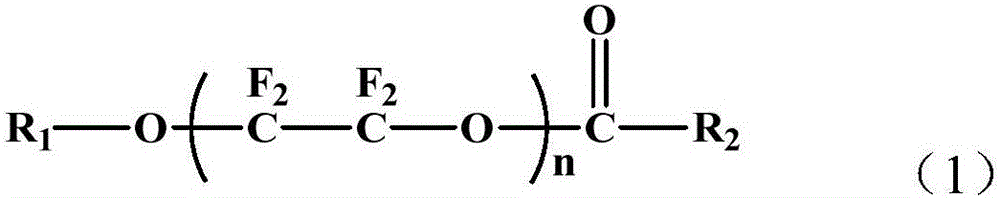

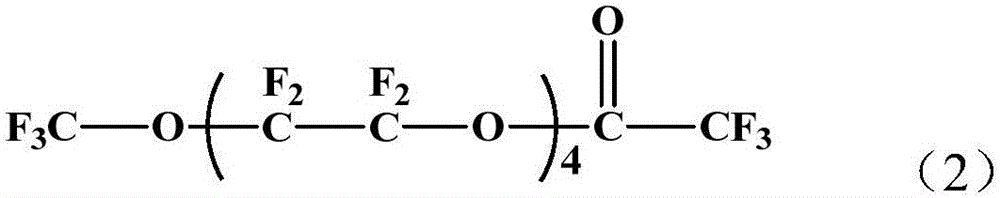

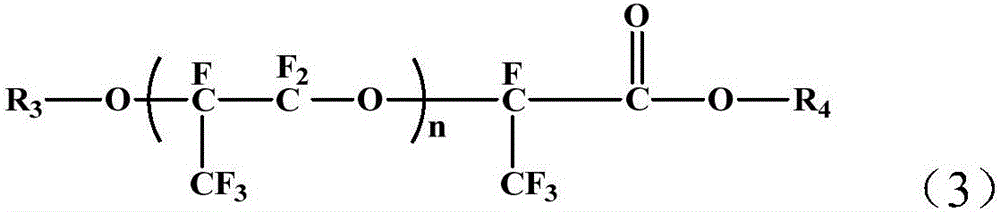

Method used

Image

Examples

Embodiment 1

[0045] Preparation of paper deacidification solution

[0046] Under magnetic stirring, add 10g of fluorononyl ether acetate into 89g of perfluorooctane solvent, stir evenly, then add 1g of magnesium oxide, and ultrasonically vibrate at room temperature for 10 minutes at an ultrasonic frequency of 20kHz to obtain Paper deacidification solution.

[0047] The particle size of magnesium oxide used in this example is 90nm.

[0048] Put the above-mentioned paper deacidification solution in a watering can, spray it evenly on the surface of the paper twice, and let the paper dry naturally at room temperature.

[0049] The paper used in the present embodiment is that quality is the single Xuan of 2g, and its quantification is 25g / m 2 .

Embodiment 2

[0051] Preparation of paper deacidification solution

[0052] Under magnetic stirring, add 1500g of fluorodecyl ether methyl ester into 7500g of perfluorooctane solvent three times, stir evenly, then add 375g of calcium oxide, and ultrasonically vibrate at room temperature for 30 minutes at an ultrasonic frequency of 40kHz. Obtain paper deacidification solution.

[0053] The particle size of calcium oxide used in this example is 200nm.

[0054] Put the above-mentioned paper deacidifying solution in a watering can, spray evenly twice on the surface of each page of paper in the book, and then carry out vacuum drying.

[0055] Books used in the present embodiment is that quality is 270g, and the number of pages is the paperback book that the hardwood pulp of 200 pages is copied, and the quantification of its paper is 50g / m 2 .

Embodiment 3

[0057] Preparation of paper deacidification solution

[0058]Under magnetic stirring, add 20g of fluoroheptyl ether acetate into 75g of perfluorooctane solvent, stir evenly, then add 5g of magnesium hydroxide, and ultrasonically vibrate at room temperature for 10 minutes at an ultrasonic frequency of 30kHz. Obtain paper deacidification solution.

[0059] The particle size of the magnesium hydroxide used in this example is 100nm.

[0060] Soak the paper in the above-mentioned paper deacidifying solution for 30 minutes, take out the paper, and let it dry naturally at room temperature.

[0061] Paper used in the present embodiment is the bamboo paper that quality is 4g, and its quantification is 20g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com