SEBS based composite membrane, preparation method of SEBS based composite membrane and infusion apparatus

A technology of composite film and infusion tube, which is applied in the field of medical materials, can solve the problems of poor adsorption inhibition, non-environmental protection, and complicated operation, and achieve the effects of improving adsorption phenomenon, low cost, and avoiding side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

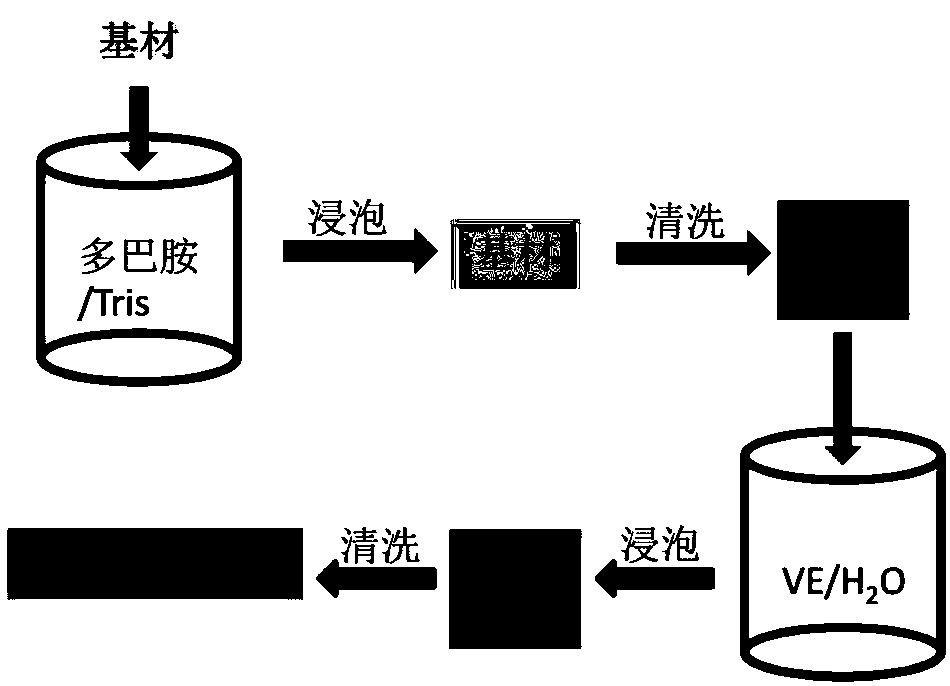

[0055] The present invention also provides a method for preparing the SEBS-based composite membrane described in the above-mentioned technical scheme, comprising the following steps:

[0056] a) soaking the SEBS substrate in a dopamine solution and drying it to obtain a dopamine-modified SEBS substrate;

[0057] b) soaking the dopamine-modified SEBS substrate in a retinoid solution and drying to obtain a SEBS-based composite membrane.

[0058] According to the present invention, the SEBS base material is first soaked in the dopamine solution and then dried to obtain the dopamine-modified SEBS base material.

[0059] In the present invention, the thickness of the SEBS substrate is not particularly limited, and it can be a film, sheet or plate, etc., that is, the present invention can construct a composite coating on the surface of various required SEBS substrates. The present invention has no special limitation on the source of the SEBS substrate, it can be a general commercia...

Embodiment 1

[0075] 1.1 Sample preparation

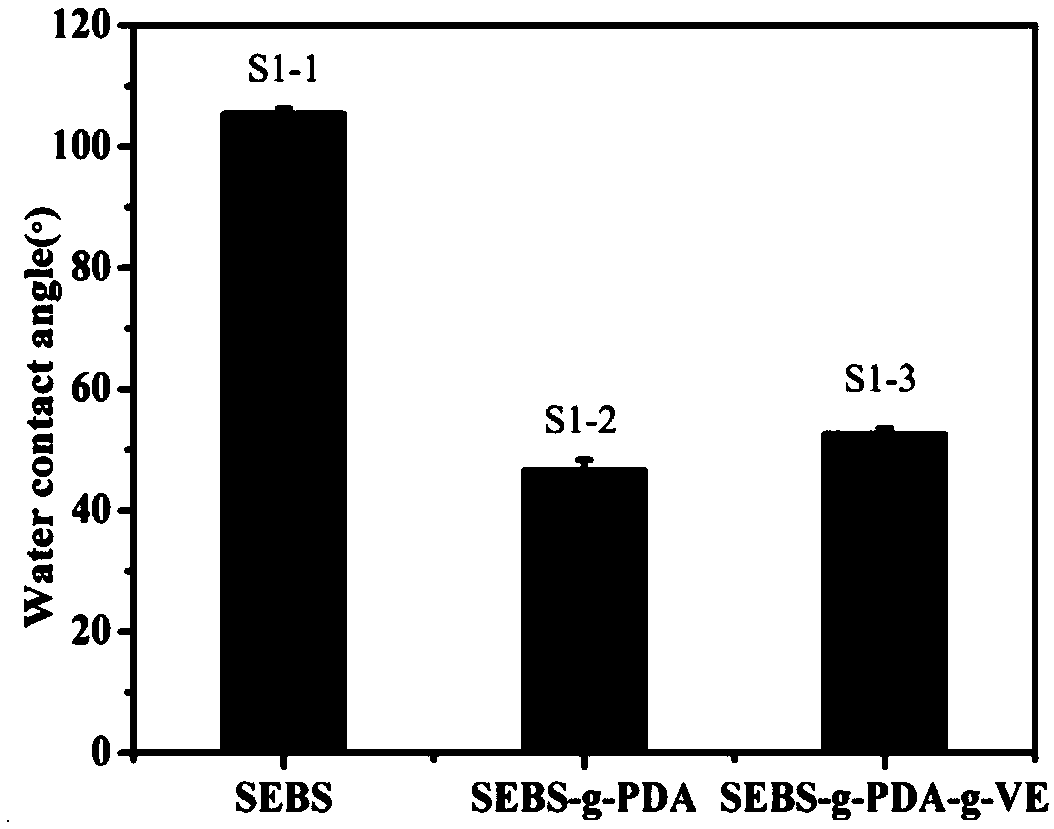

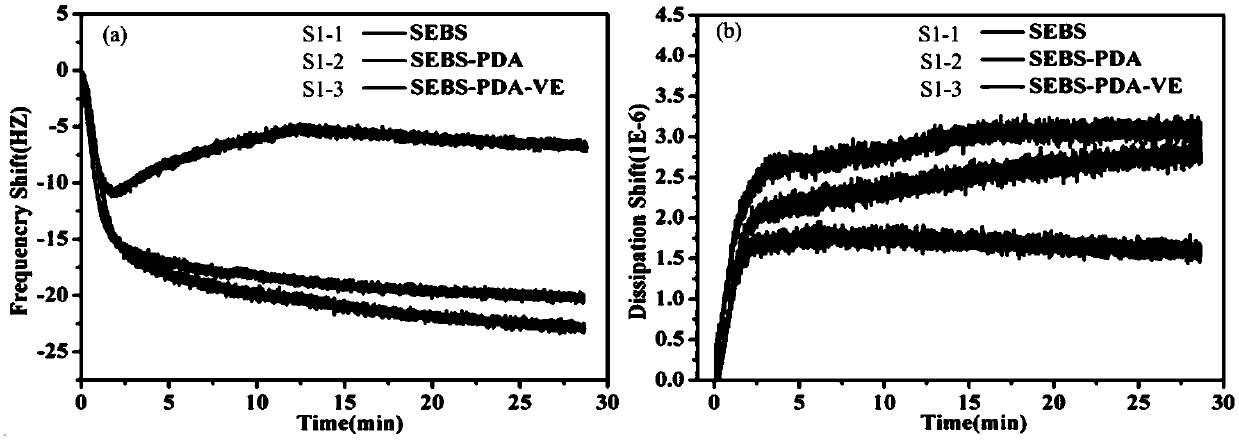

[0076] Prepare a 2wt% SEBS / toluene solution, stir overnight at room temperature, and after standing for 6 hours, take 100 μL SEBS / toluene solution and evenly drop it on the QCM-D gold chip, spin coat it at 5000 rpm for 20 seconds with a spin coater, and place it in an oven at 40 °C After drying for 3 hours, a SEBS film was formed on the QCM-D gold chip; three copies were made in parallel according to the above process, labeled S1-1, S1-2 and S1-3 respectively.

[0077] Samples S1-2 and S1-3 were respectively immersed in dopamine / Tris-HCl solution, wherein the concentration of dopamine was 5 mg / mL, and the pH of Tris-HCl buffer was 8.5; soaked for 12 hours at room temperature, and washed three times with deionized water , blown dry with nitrogen (vacuum degree is -0.05MPa, temperature is 25°C), and a polydopamine layer is formed on the surface of the SEBS film.

[0078] Take the sample labeled S1-3 and continue to put it into 200μg / mL vitamin E ...

Embodiment 2

[0086] 1.1 Sample preparation

[0087] Prepare a 2wt% SEBS / toluene solution, stir overnight at room temperature, and after standing for 6 hours, take 100 μL SEBS / toluene solution and evenly drop it on the QCM-D gold chip, spin coat it at 5000 rpm for 20 seconds with a spin coater, and place it in an oven at 40 °C Dry for 3 hours to form a SEBS film on the QCM-D gold chip; make two copies in parallel according to the above process, labeled S2-1 and S2-2 respectively.

[0088] Samples S2-1 and S2-2 were respectively immersed in dopamine / Tris-HCl solution, wherein the concentration of dopamine was 5 mg / mL, and the pH of Tris-HCl buffer was 8.5; soaked at room temperature for 12 hours, rinsed three times with deionized water , blown dry with nitrogen (vacuum degree is -0.05MPa, temperature is 25°C), and a polydopamine layer is formed on the surface of the SEBS film.

[0089] Continue to put samples S2-1 and S2-2 into different concentrations of vitamin E derivatives (vitamin E po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com