SEBS-based granules, preparation method thereof, extrusion membrane for infusion apparatus and infusion apparatus

A technology of base granules and granules, which is applied in its preparation, extruded film for infusion sets and infusion sets, SEBS base granules, can solve the problems of non-environmental protection, complicated operation, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention also provides a method for preparing SEBS-based pellets described in the above technical solution, comprising:

[0052] a) melting and blending the raw materials to obtain a blend;

[0053] b) extruding the blend into pellets to obtain SEBS-based pellets.

[0054] Wherein, the types and ratios of the components of the raw materials are consistent with those described in the above-mentioned technical solution, and will not be repeated here.

[0055] In the present invention, each raw material is preferably dried first before melt blending. The temperature for drying the raw materials is preferably 40-120°C, more preferably 50-80°C; the drying time is preferably 2-12 hours, more preferably 4-8 hours. After the raw materials are dried, they are preferably further mixed, and after uniform mixing, a mixed material is obtained.

[0056] After the mixture is obtained, the mixture is melt-blended to obtain a blend. The temperature of the melt-blending ...

Embodiment 1

[0063] 1.1 Material preparation

[0064] Weigh 70g of SEBS (brand YH506), 20g of dopamine, and 10g of vitamin E, dry in an oven at 80°C for 24h and mix well; then put it into an internal mixer for melt blending, the temperature of melt blending is 180°C, and the time is 10min , and the rotation speed was 100 rpm / min to obtain a blend. Put the obtained blend into a granulator to extrude and granulate to obtain SEBS-based pellets.

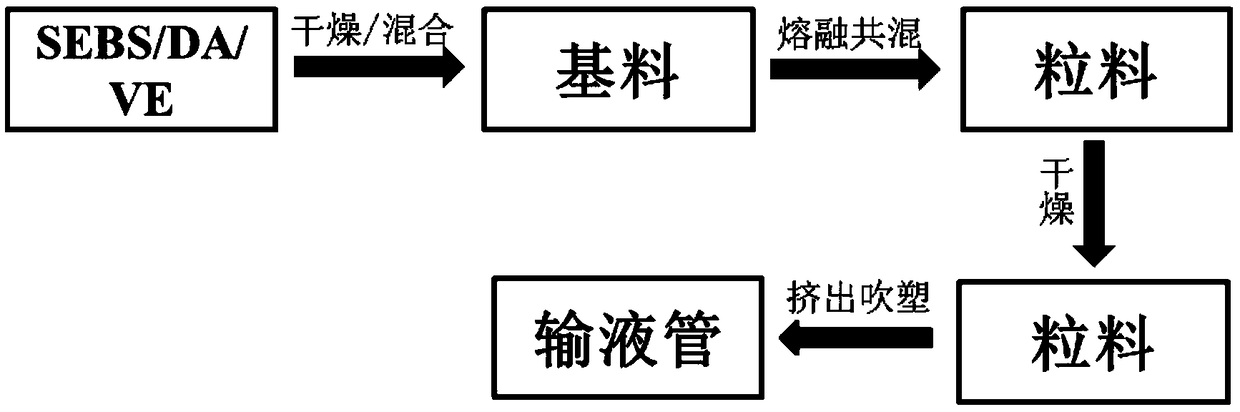

[0065] Dry the obtained SEBS-based pellets in an oven at 80°C for 24 hours, and then add them to a single-screw extruder with a head temperature of 160-200°C, a barrel temperature of 180-190°C, a residence time of 10 minutes, and extrude Pull the tube to obtain an infusion catheter with a diameter of 4 mm (denoted as sample S1). The preparation process of embodiment 1 is as figure 1 as shown, figure 1 Be the preparation flowchart of embodiment 1.

[0066] Preparation of control samples:

[0067] Only 70 g of SEBS was weighed, and an infusion ca...

Embodiment 2

[0075] 1.1 Material preparation

[0076] Weigh SEBS (brand name is G1652) 60g, 25g of dopamine, 15g of vitamin E, dried in an oven at 80°C for 24h and then mixed; then put into an internal mixer for melt blending, the temperature of melt blending is 180°C, the time is 10min, and the speed is 100rpm / min , to obtain a blend. Put the obtained blend into a granulator to extrude and granulate to obtain SEBS-based pellets.

[0077] Dry the obtained SEBS-based pellets in an oven at 80°C for 24 hours, and then add them to a single-screw extruder with a head temperature of 160-200°C, a barrel temperature of 180-190°C, a residence time of 10 minutes, and extrude Pull the tube to obtain an infusion catheter with a diameter of 4 mm (denoted as sample S2).

[0078] 1.2 Material adsorption test

[0079] According to the test process of Example 1, the adsorption test of the obtained sample S2 was carried out, and the results showed that within 60 minutes, the adsorption rate of the samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com