Method for purifying alkyl hydroperoxide by extraction with water and separation of the aqueous phase

An alkyl hydroperoxide, alkyl peroxide technology, applied in separation methods, peroxy compound preparation, chemical instruments and methods, etc., can solve the problems of low productivity, difficulty in purifying alkyl hydroperoxides, and the like, Minimize risks, avoid side effects, and reduce safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] Preparation of hydroperoxide

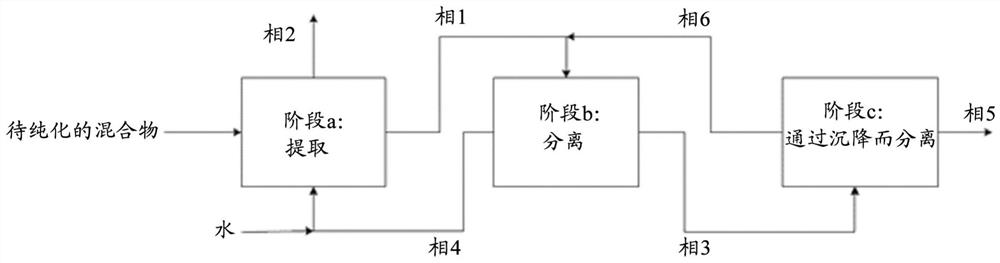

[0078] As indicated above, the process according to the invention involves the purification of a mixture comprising at least one alkyl hydroperoxide and at least one dialkyl peroxide.

[0079] Preferably, said mixture is obtained after the preparation of the alkyl hydroperoxide in question.

[0080] In other words, the process according to the invention is aimed at purifying the alkyl hydroperoxides obtained by synthesis.

[0081] Preferably, the alkyl hydroperoxides can be prepared in acidic media.

[0082] In other words, the process according to the invention may comprise, prior to stage a), a stage a') of synthesis of said alkyl hydroperoxide in an acidic medium.

[0083] In this case, the process for the preparation of alkyl hydroperoxides consists in particular in reacting aqueous hydrogen peroxide in an acidic medium in the presence of at least one alcohol or at least one olefin.

[0084] Preferably, the process for the prepara...

Embodiment 1

[0199] starting mixture

[0200] In the examples below, the mixture treated was a mixture containing 84.6% tert-amyl hydroperoxide, 4% di(tert-amyl)peroxide (DTA), 0.8% acetone, 0.8% tert-amyl alcohol and 0.9% by weight The peroxide 2,2-bis(tert-amylperoxy)propane in tert-amyl hydroperoxide (TAHP) solution.

[0201] Extraction stage a)

[0202] In a closed flask, 500 ml of demineralized water was added to 41.2 g of the above tert-amyl hydroperoxide solution.

[0203] The combined product was mixed for 30 minutes using a magnetic stir bar and then allowed to separate by settling at ambient temperature for a period of 30 minutes.

[0204] After this separation by settling, about 12.5 g of a supernatant organic phase (with interface) and about 528 g of a slightly cloudy lower phase formed.

[0205] Concentration stage b)

[0206] The lower phase was introduced into a rotary evaporator flask.

[0207] The distillation was carried out at a bath temperature of 50° C. at a...

Embodiment 2

[0211] starting mixture

[0212] In the examples below, the treated mixture was a mixture containing 84.6% tert-amyl hydroperoxide, 4% di(tert-amyl)peroxide (DTA), 0.8% acetone, 0.8% tert-amyl alcohol, and 0.9 % by weight peroxide 2,2-bis(tert-amylperoxy)propane in tert-amyl hydroperoxide (TAHP) solution.

[0213] The starting mixture is the same as that of Example 1.

[0214] Extraction stage a)

[0215] In a closed flask, 500 ml of demineralized water was added to 41.2 g of the above tert-amyl hydroperoxide solution.

[0216] The combined product was mixed for 30 minutes using a magnetic stir bar and then allowed to separate by settling at ambient temperature for a period of 60 hours.

[0217] After this separation by settling, about 11.5 g of a supernatant liquid phase and about 526 g of a lower phase were formed.

[0218] Concentration stage b)

[0219] A quantity of 428 g of the lower phase was introduced into the rotary evaporator flask.

[0220] The distilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com