An automatic tensioning system and method for prestressed fiberboard reinforced beams and slabs

A fiberboard and prestressing technology, which is applied in bridge reinforcement, bridge, building maintenance, etc., can solve the problems of not reaching the fiberboard tensile elongation value, limited stroke of hydraulic jack, waste of materials, etc., to save labor costs and ensure safety Sexuality and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

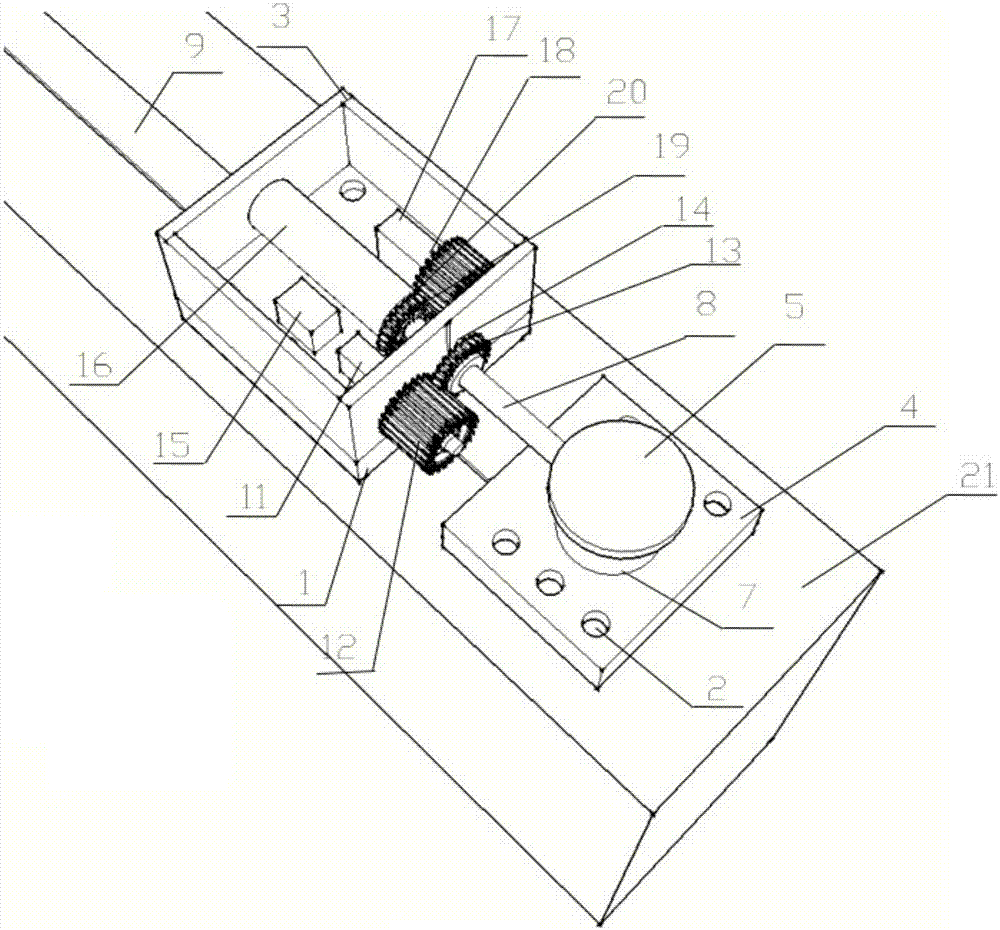

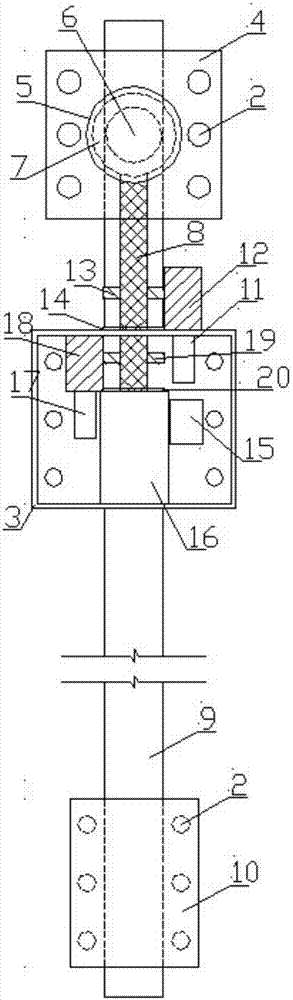

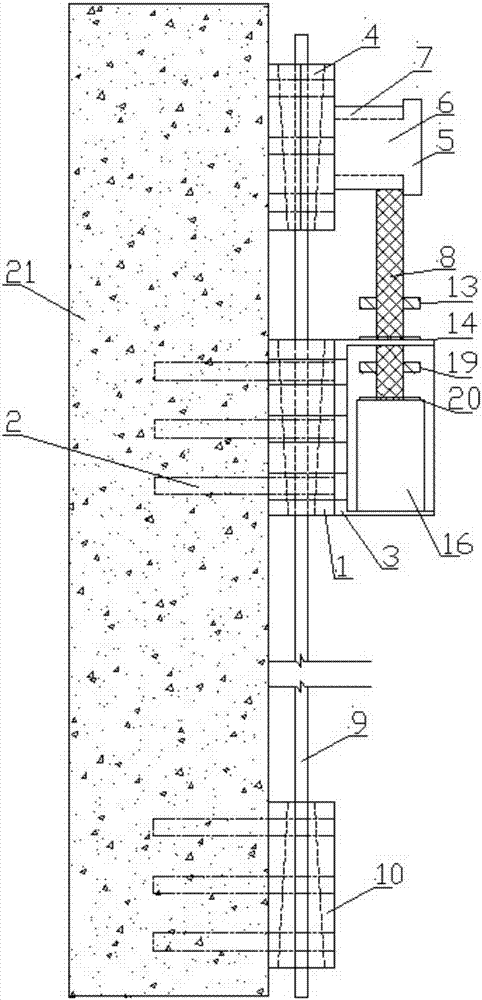

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

[0035] Such as Figure 1 to Figure 3 As shown, an automatic tensioning system for prestressed fiberboard reinforced beams and slabs includes a tensioning end anchor 1, a fixed end anchor 10, a tensioning bracket 3 connected to the tensioning end anchor 1; the middle part of the tensioning bracket 3 A through-type jack 16 is set, and the threaded rod 8 is connected with the through-type jack 16 after passing through the tension bracket 3, and an upper toothed nut 13 and a lower toothed nut 19 are respectively arranged on both sides of the tension bracket 3 on the threaded rod 8, The upper toothed nut 13 and the lower toothed nut 19 are respectively driven by a driving mechanism. The driving mechanism includes a left motor 17 and a right motor 11; it also includes a two-point clamp 4, and the upper surface of the clamp 4 is fixedly provided with a cylinder 6. The sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com