Bulkhead wall type supporting and blocking structure with oblique piles and relieving slabs combined

A technology of retaining structure and unloading plate, which is applied in the direction of shore wall, underwater structure, foundation structure engineering, etc., can solve the problems of increased stress and deformation of the front wall, large deformation of the top of the anchor structure, and complicated construction process. Achieve the effect of improving horizontal resistance, improving the overall anti-sliding safety and stability coefficient, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

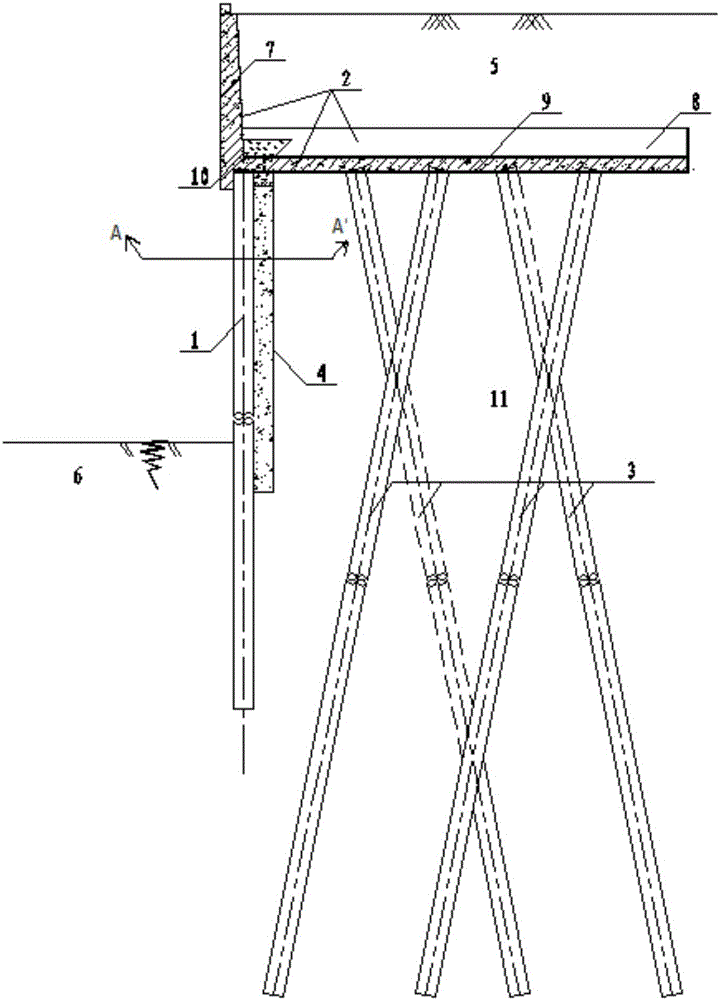

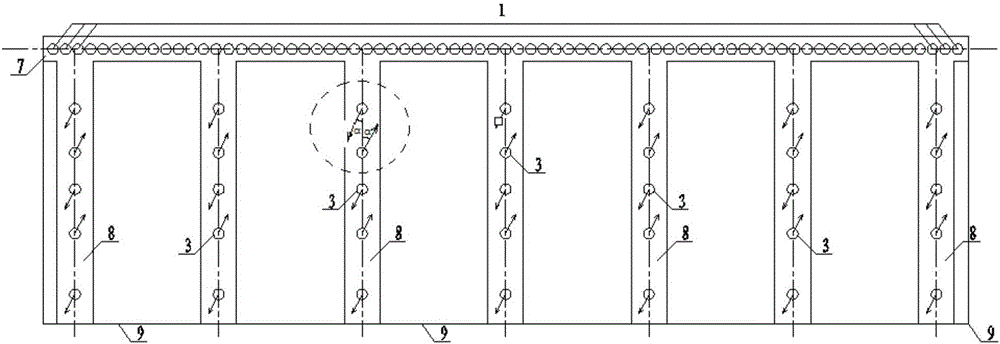

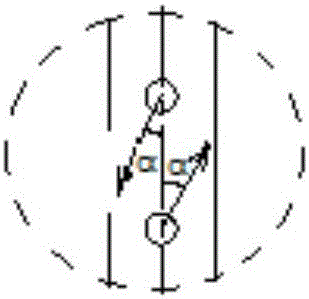

[0041] This embodiment is the application of the quay wall structure in wharf engineering. The overall structure is as follows figure 1shown. There are 12 expansion sections in total, each expansion section is 50.4m long, the expansion joint is 3cm wide, and the total length is 600m. The longitudinal pile foundation at the front of the wharf is a prefabricated row of piles with a pile spacing of 70cm. Prestressed concrete PHC-600(110)B-C80 pipe piles are selected. Two rows of φ600 mixing piles are placed behind the piles, and the center distance between the piles is 500mm. Cast-in-place L-shaped cap 2, the elevation of the bottom of the beam is 3.70m, the elevation of the top of the cap is 4.70m, the distance between the centers of the cap bottom beams 8 is 4m, and each cap bottom beam 8 is arranged with 5 PHC-600(110)AB- C80, the pile length is 30 meters, the small transverse angle α adopted for the inclined pile layout is 15°, and the inclination angle is 5:1, two of which ...

Embodiment 2

[0043] This embodiment is the application of the quay wall structure in another wharf project. The total length of the wharf is 400m, the length of the standard expansion section is 28.5m, and the width of the expansion joint is 2cm. The longitudinal pile foundation at the front of the wharf is a prefabricated sheet pile, the size of the sheet pile is 500*600 (thickness*width), and a row of φ500@40 high-pressure powder sprayed mixing piles is arranged behind the piles. Cast-in-place L-shaped cap 2, the beam bottom elevation is 3.70m, the cap beam top elevation is 4.70m, fire water tank 12 is installed behind the front wall 7; 6 pieces of PHC-600(110)AB-C80 are arranged, the pile length is 30 meters, and the small transverse angle α adopted by the forward or reverse inclined pile arrangement is 16° and the inclination angle is 4:1. Fill soil (drought sand) on the back deck of the front wall of the wharf to an elevation of 7.50m on the wharf surface. The overall anti-sliding s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com