Self-lubricating sleeve type spiral centralizer

A technology of self-lubricating sleeves and centralizers, which is applied in the direction of engine lubrication, casing, sliding contact bearings, etc., can solve the problems of logging-while-drilling instrument failure, poor use of vertical drilling instruments, etc., to reduce the risk of pipe sticking, Effect of reducing vibration and increasing effective length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment, the self-lubricating sleeve type spiral centralizer structure of the present invention is further described:

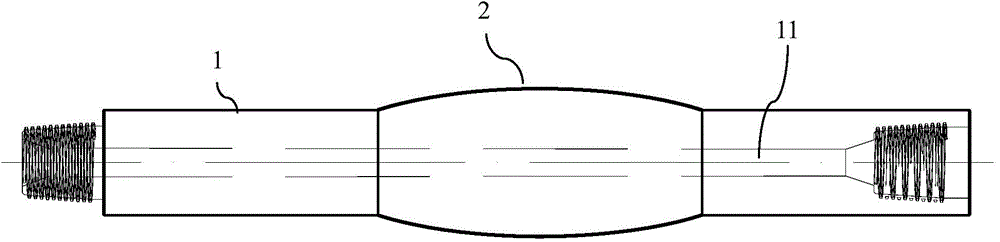

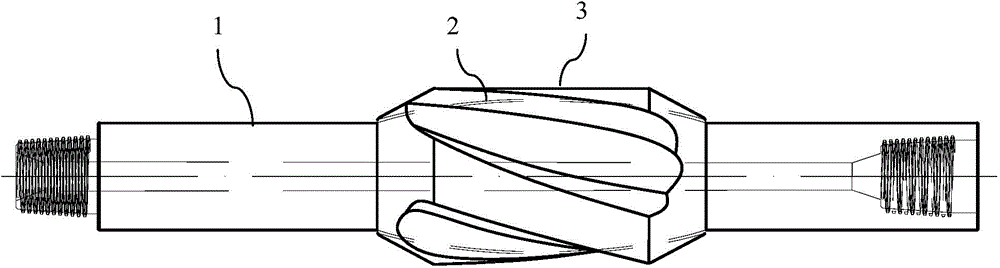

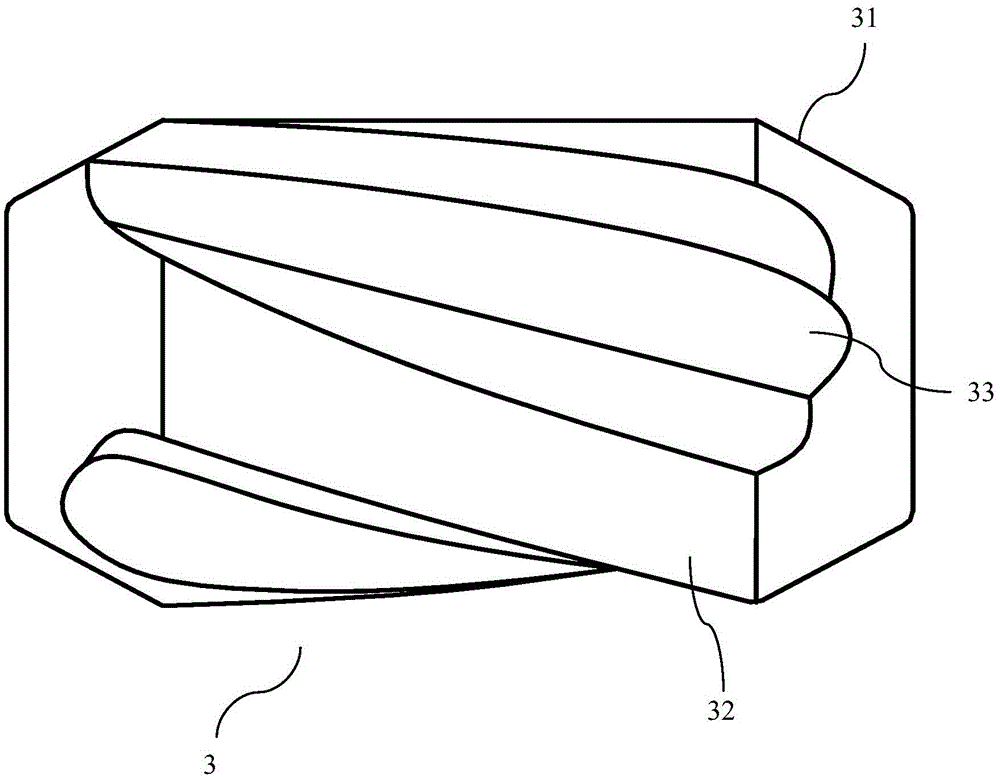

[0020] like figure 1 As shown, a self-lubricating sleeve type spiral centralizer includes a centralizer body 1, the centralizer body 1 is cylindrical, its central axis is provided with a through hole 11, and the outer circumference of the centralizer body 1 is formed with a The inner ring body 2 protruding radially outward, the inner ring body 2 is formed by gradually reducing its diameter in the axial direction toward both ends, and the two ends of the inner ring body 2 gradually transition to the outer peripheral surface of the centralizer body 1, Preferably, the inner ring body 2 is formed by gradually reducing the diameter from the middle position of the inner ring body 2 toward both ends in the axial direction, which facilitates the assembly with the sleeve 3 described below, and makes the stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com