Composite permanent magnet motor direct driven walking beam type oil pumping machine

A technology of beam pumping units and composite motors, which is applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of limited energy saving of the system, practical application value of beam pumping units, and difficulties in gearboxes, etc. , to achieve the effect of reducing maintenance, improving system reliability and reducing driving links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

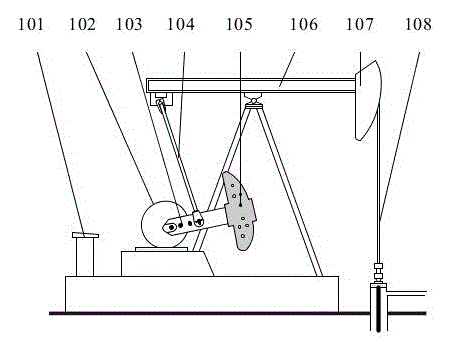

[0014] The direct drive beam pumping unit has a permanent magnet compound motor 102 , a control cabinet 101 , a crank 103 , a connecting rod 104 , a balance weight 105 , a beam 106 , a donkey head 107 and a polished rod 108 .

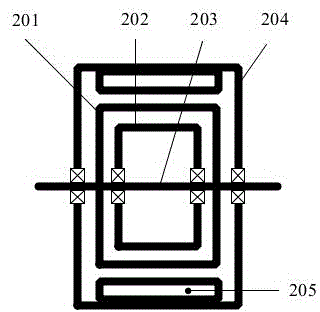

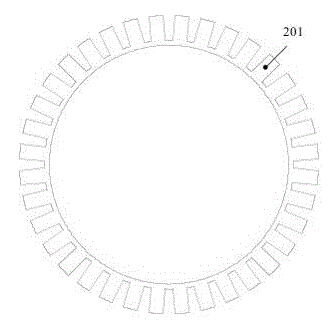

[0015] The permanent magnet composite motor 102 is controlled by the control cabinet 101, and the control cabinet 101 is powered by the grid. The control cabinet 101 controls the high-speed rotor 202 of the permanent magnet composite motor 102 through frequency conversion, and the high-speed rotor 202 drives the permanent magnet composite motor 102 after being decelerated by the magnetic field. The low-speed rotor 201 of the permanent magnet composite motor 102 is rigidly connected with the double output main shaft 203 of the permanent magnet composite motor, thereby driving the crank 103 of the beam pumping unit to rotate, and the crank 103 is connected to the traveling beam through the connecting rod 104 The tail of the beam 106 is connected, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com