Lock control non-return joint ball valve

A joint ball and check technology, which is applied in the direction of control valves, valve details, valve devices, etc., can solve the problems of lack of lockable check ball valves with joints, etc., to eliminate the hidden danger of screw loss, compact structure, and reduce safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

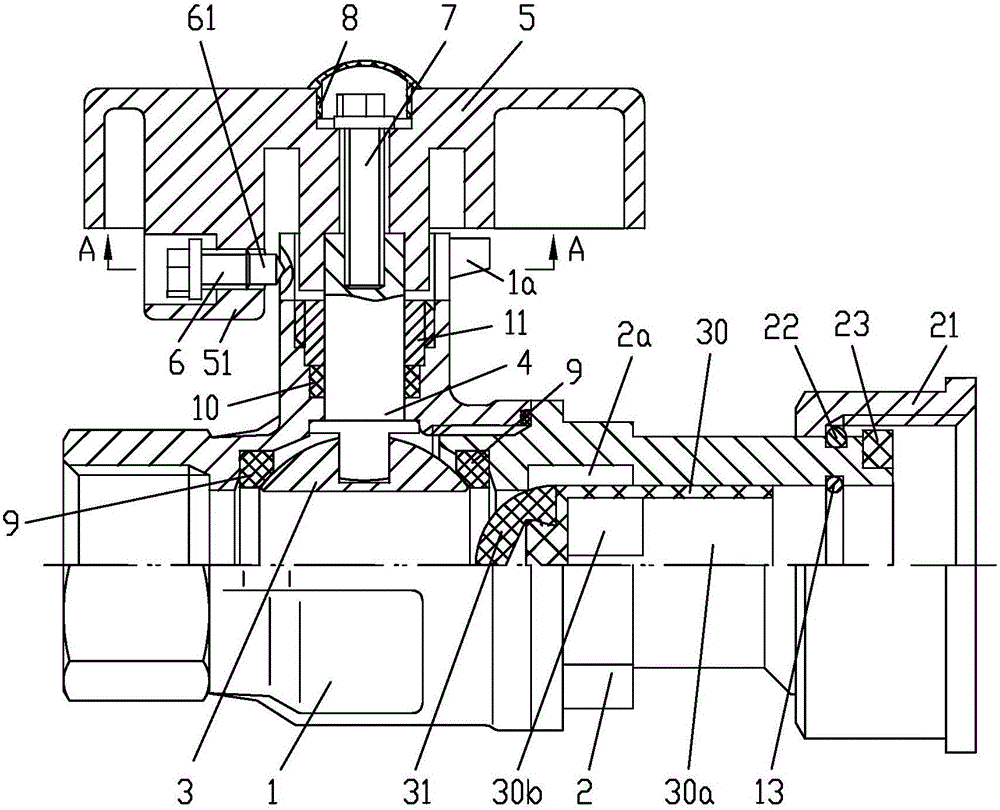

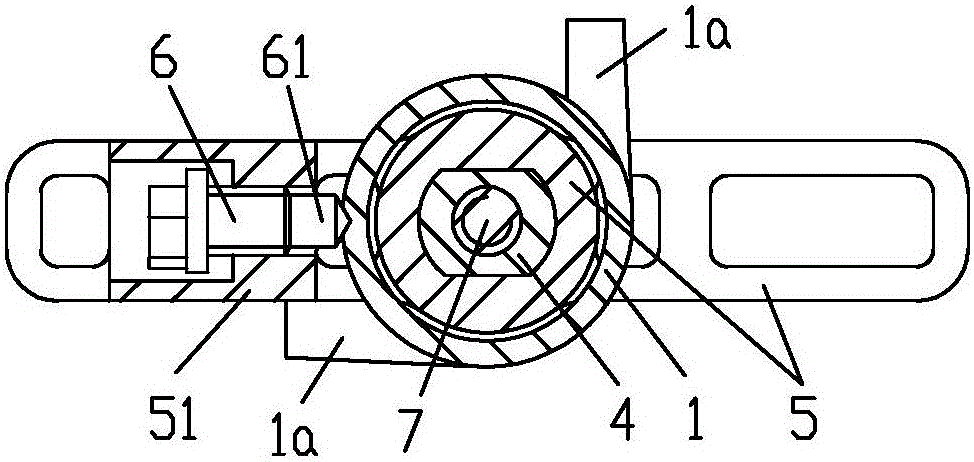

[0022] Example 1, see figure 1 , figure 2 , image 3 , a lock control check joint ball valve, comprising a valve body 1 and a valve cover 2, the external interface of the valve cover 2 constitutes a flexible joint structure, and a check valve structure is formed on the fluid passage of the valve cover 2; the valve body 1 and the valve cover The valve core 3 is connected between the cover 2 through the sealing seat ring 9, the valve core 3 is connected with the wrench 5 through the valve stem 4; There is a sealing packing 10 between the inner wall of the packing chamber, and the sealing packing 10 is pressed by the packing nut 11 to form a sealed connection between the valve stem 4 and the valve body 1; the wrench 5 is T-shaped, and the wrench 5 passes through the middle of the T-shaped The vertical part is sleeved on the outer end of the valve stem 4, and forms a torque transmission structure through two parallel flat surfaces, and the outer end of the valve stem 4 is hidde...

Embodiment 2

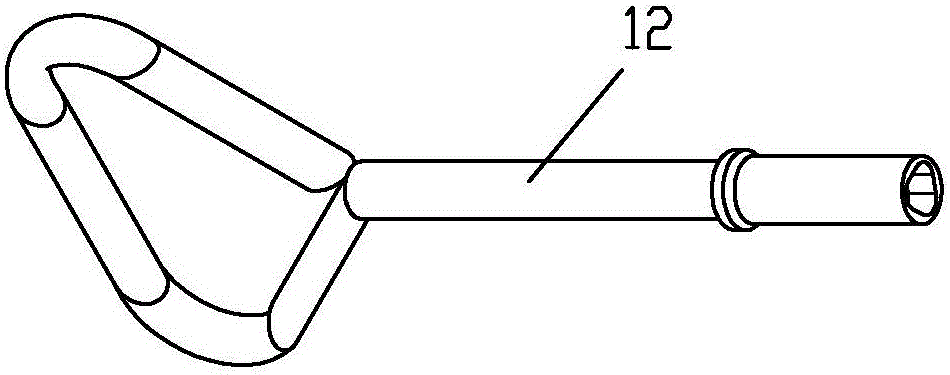

[0026] Example 2, see Figure 4 , the locking screw 6 is screwed on the outer wall of the stuffing chamber of the valve body 1, and the limit stop tongue 51 is located outside the head of the lock screw 6, so that when the lock screw 6 is tightened, the wrench 5 can rotate, and the limit stop tongue There is a perforation 52 horizontally on the 51, and the diameter of the perforation 52 is larger than the outer diameter of the screw opening tool 12 that can be inserted into the section, so that the locking screw 6 can be turned by the screw opening tool 12, so that the head of the locking screw 6 can extend into a part of the perforation 52, Thereby, the locking of the wrench 5 is formed; or, the locking screw 6 is twisted by the screw opening tool 12, so that the head of the locking screw 6 escapes from the perforation 52 and is positioned inside the limit stop tongue 51, thereby releasing the locking state of the wrench 5.

[0027] The rest of the structure of this embodimen...

Embodiment 3

[0028] Example 3, see Figure 5 , Image 6 , the head 61 of the locking screw 6 is formed with a triangular hole-shaped tightening structure, so as to be screwed only by the screw opening tool 12a matched therewith, and the screw opening tool 12a has a tightening structure with the front end of the locking screw 6 Matching triangular prism-shaped head.

[0029] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com