High-toughness abrasion-resistant PVC hose and processing method thereof

A high toughness, PVC-5 technology, applied in the direction of hose, pipe, pipe/pipe joint/pipe fitting, etc., can solve the problems of unreasonable rib structure of PVC plastic hose, unreasonable inner and outer layer structure design, etc. Long life and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

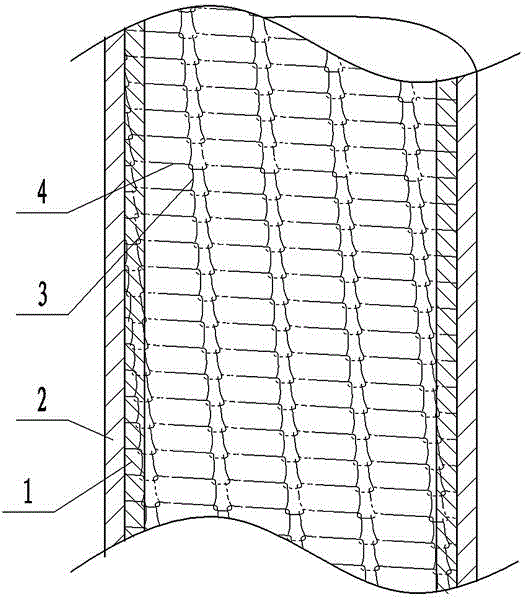

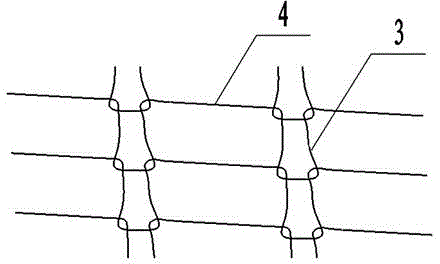

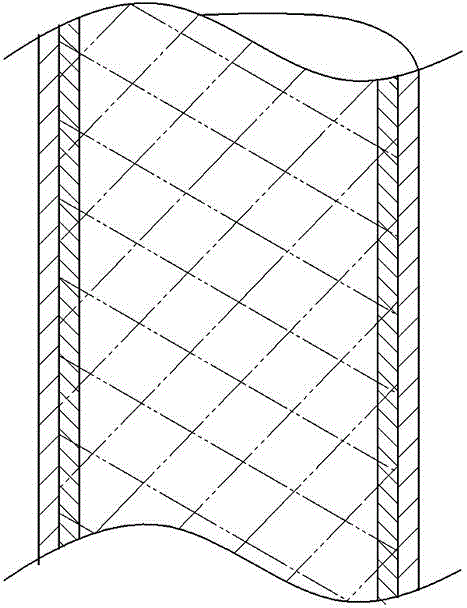

[0019] Embodiment one: if figure 1 and figure 2 Shown: a high-toughness wear-resistant PVC hose, a layer of ribs 4 is processed between the inner layer 1 and the outer layer 2 of the pipe body, and the inner layer 1 of the pipe body is an elastic layer composed of high-toughness material. The outer layer 2 of the body is a wear-resistant layer made of wear-resistant materials, and the rib layer 4 is woven with nylon thread, which is wound on the inner layer 1 circle by circle, and the upper line of the winding line is pulled out of the concave sleeve. Circle 3, the downline passes through the loop 3, the downline is also pulled out of the downward loop 3 at the position of the loop 3, and the next line of winding passes through the loop 3, and the coils are connected to each other. The sleeve forms a rib layer; the high-toughness material constituting the inner layer 1 of the pipe includes sheet materials in parts by weight: 30 parts of PVC-5 resin, 0.5 part of 901 light sta...

Embodiment 2

[0020] Embodiment two: the high-toughness wear-resistant PVC hose as described in embodiment one, its processing method comprises the following steps,

[0021] 1. Calculated in parts by weight, the raw materials that will constitute the inner layer of the pipe, PVC-5 resin: 30 parts, 901 light stabilizer: 0.5 parts, styrene-butadiene rubber: 5 parts, disproportionated rosin: 0.6 parts, stearamide: 1 Parts, Diethylene glycol monomethyl ether: 0.6 parts; Stir evenly in the first high-speed mixer;

[0022] Put the uniformly stirred inner layer raw materials into the first screw extruder and heat to 130 0 C. Extrude from the extrusion head, and circulate and cool the melted raw material with purified clean water at normal temperature on the forming die of the pipe body to cool it down to 80 0 Below C forms the inner layer of the pipe body;

[0023] 2. Install the netting machine after the first screw extruder, let the inner layer of the pipe body pass through the braiding head o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com