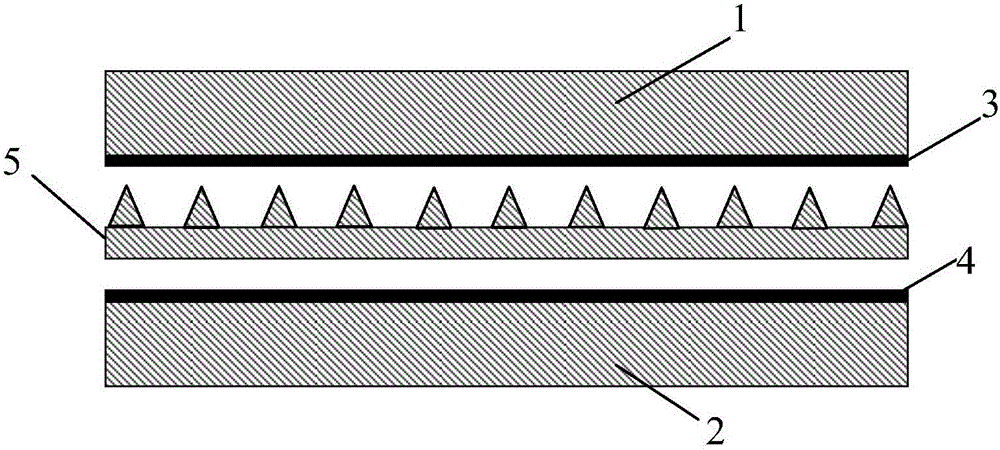

Capacitive flexible pressure sensor based on microstructural dielectric layers and preparation method of capacitive flexible pressure sensor

A pressure sensor and micro-structured technology, applied in the field of sensors, can solve the problem that the sensitivity and stability of the sensor need to be further improved, and achieve the effects of being conducive to application promotion, low energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

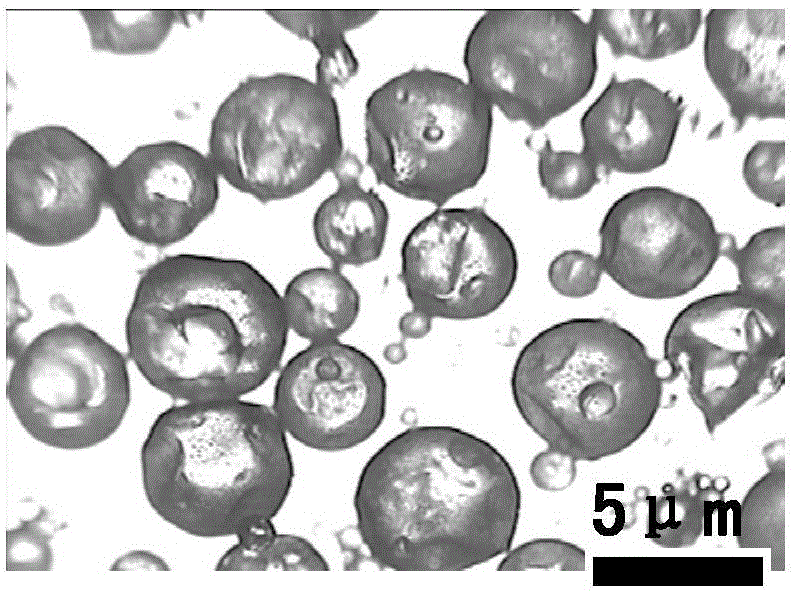

[0065] (1) Preparation of flexible substrate

[0066] The commercially available PDMS monomer and curing agent (Dow Corning, SYLGARD 184, the United States) were fully mixed according to the mass ratio of 10:1, and OSP-100 Meyer rods (OSP-100, Shijiazhuang OSP Machinery Technology Co., Ltd. ) on the surface of commercially available inkjet printing paper (Canon, LU-101 professional suede photo paper, Japan), and then placed in a vacuum oven at room temperature for 5 minutes to remove air bubbles in the coating, and then cured at 70 ° C for 2 hours, and peeled off from the surface of the photo paper to obtain a flexible substrate with a thickness of 100 μm.

[0067] (2) Preparation of conductive layer and electrodes

[0068] Using screen printing (screen printing machine: OS-500FB, China Outlet Printing Machinery Industry Co., Ltd.), print nano-silver conductive ink (AP02, Beijing Beiyin Zhongyuan Technology Co., Ltd.) on the surface of the flexible substrate to obtain a condu...

Embodiment 2

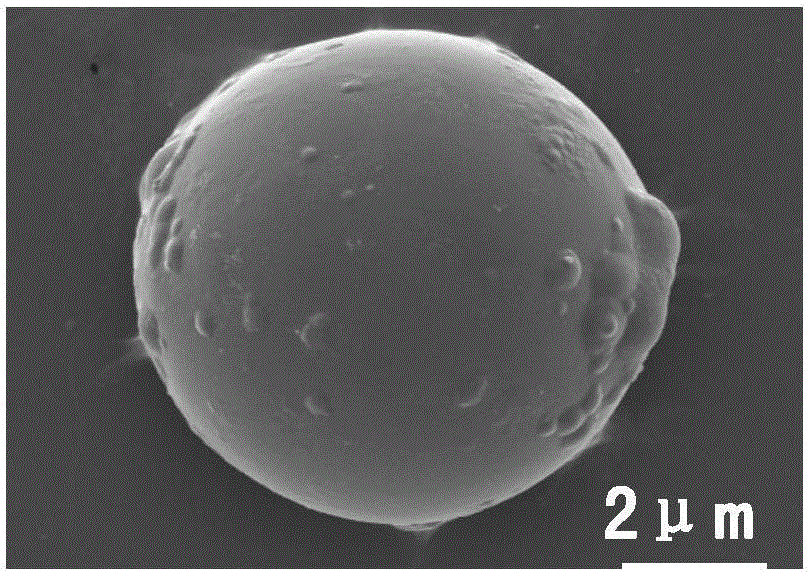

[0080] (1) Preparation of flexible substrate

[0081] The commercially available PDMS monomer and curing agent (Dow Corning, SYLGARD 184, the United States) were fully mixed according to a mass ratio of 10:1, and OSP-1.5 Meyer rods (OSP-1.5, Shijiazhuang OSP Machinery Technology Co., Ltd. ) on the surface of commercially available inkjet printing paper (Canon, LU-101 professional suede photo paper, Japan), and then placed in a vacuum oven at room temperature for 5 minutes to remove air bubbles in the coating, and then cured at 70 ° C for 2 hours, and peeled off from the surface of the photo paper to obtain a flexible substrate with a thickness of 1 μm.

[0082] (2) Preparation of conductive layer and electrodes

[0083] On the surface of the flexible substrate, the carbon nanotube conductive layer (TNWPM, Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences) was prepared by coating the OSP-1.5 Meyer rod (OSP-1.5, Shijiazhuang OSP Machinery Technology Co., Ltd.), w...

Embodiment 3

[0091] (1) Preparation of flexible substrate

[0092] The commercially available PDMS monomer and curing agent (Dow Corning, SYLGARD 184, the United States) were fully mixed according to the mass ratio of 10:1, and the OSP-50 Meyer rod (OSP-50, Shijiazhuang OSP Machinery Technology Co., Ltd. ) was coated on the surface of a commercially available PET film (Lucky, China, with a thickness of 100 μm), then placed in a vacuum oven at room temperature for 5 minutes to remove air bubbles in the coating, and then cured at 70°C for 2 hours, and removed from the surface of the photo paper Peel off to obtain a flexible substrate with a thickness of 50 μm.

[0093] (2) Preparation of conductive layer and electrodes

[0094] A gold coating is prepared by depositing on the surface of the flexible substrate by means of chemical deposition, and its surface resistance is 5Ω / sq. Use silver conductive glue (Ablestik, Ablebond 84-1Limisr4) to form upper and lower conductive electrodes on the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com