Inorganic encapsulation direct-plug type violet LED and manufacturing method thereof

An in-line, purple-light technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as easy failure and dead lights, and achieve the effects of improving heat dissipation performance, expanding application range, and improving anti-aging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

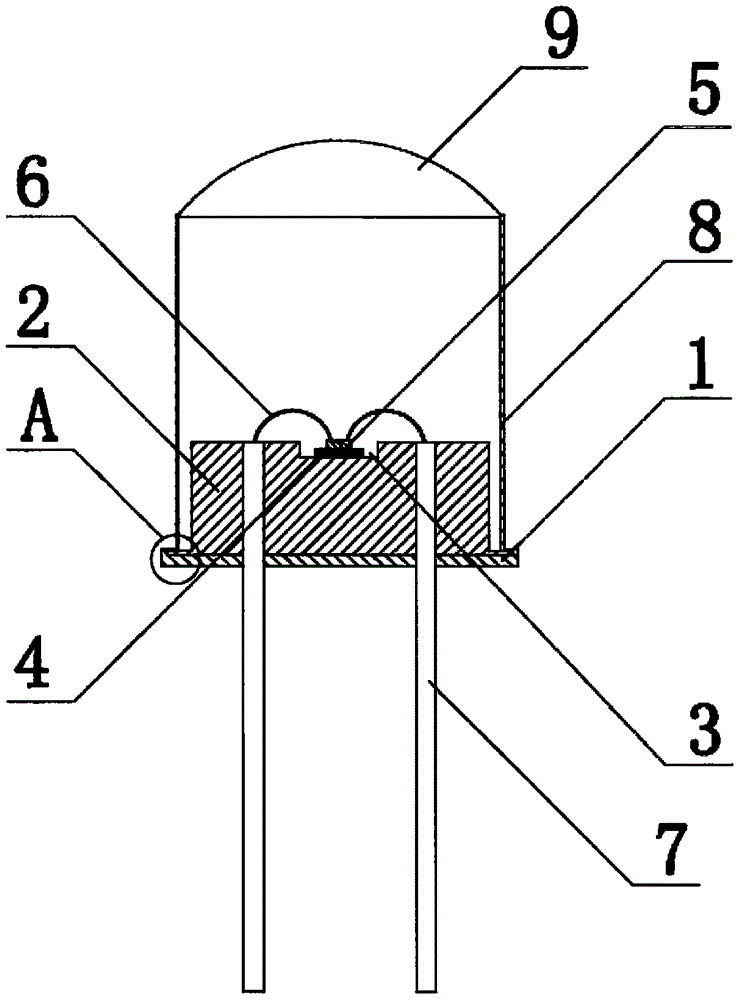

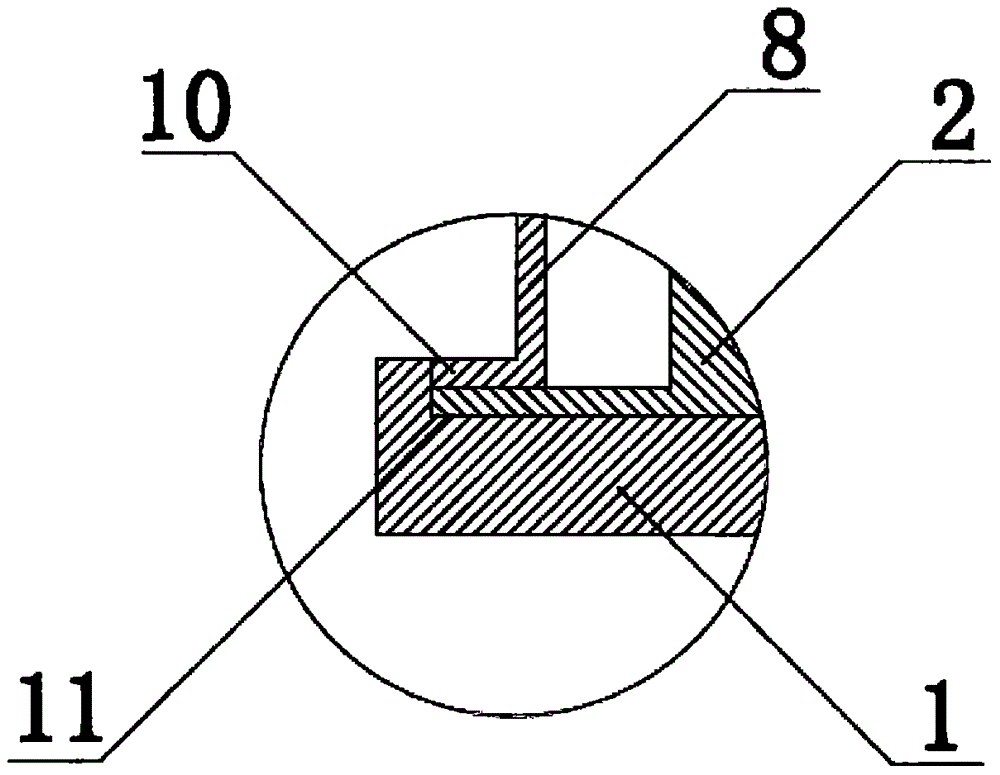

[0018] Example: such as figure 1 and figure 2 As shown, an inorganic package in-line violet LED includes a cermet base, the upper part of the cermet base is a metal part 2, the lower part is a ceramic part 1, and the center of the upper surface of the metal part 2 is provided with an inwardly concave Groove 3, a layer of crystal-bonding adhesive 4 is arranged on the inner bottom of the groove 3, and a Ziguang chip 5 is fixed on the crystal-bonding glue 4. The height of the crystal-bonding glue 4 is 1 / 3-1 / 2 of the height of the Ziguang chip 5, A pair of supply electrodes 7 runs through the cermet base, and each pair of supply electrodes 7 is connected to the purple light chip 5 through a bonding gold wire 6. A glass metal cap is buckled on the cermet base, and the glass metal cap further includes a two-end The metal tube 8 of the opening and the glass cover 9 embedded in the upper port of the metal tube 8, the glass cover 9 is a frustum-shaped convex lens sheet.

[0019] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com