A method for installing and connecting magnesium anode rods for water storage water heaters

A connection method and technology of magnesium anode, applied in the field of material processing, can solve the problems of low bonding strength between the iron core and the anode rod, prone to crevice corrosion, cumbersome assembly procedures, etc., to reduce interface resistance, avoid crevice corrosion, and improve welding quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

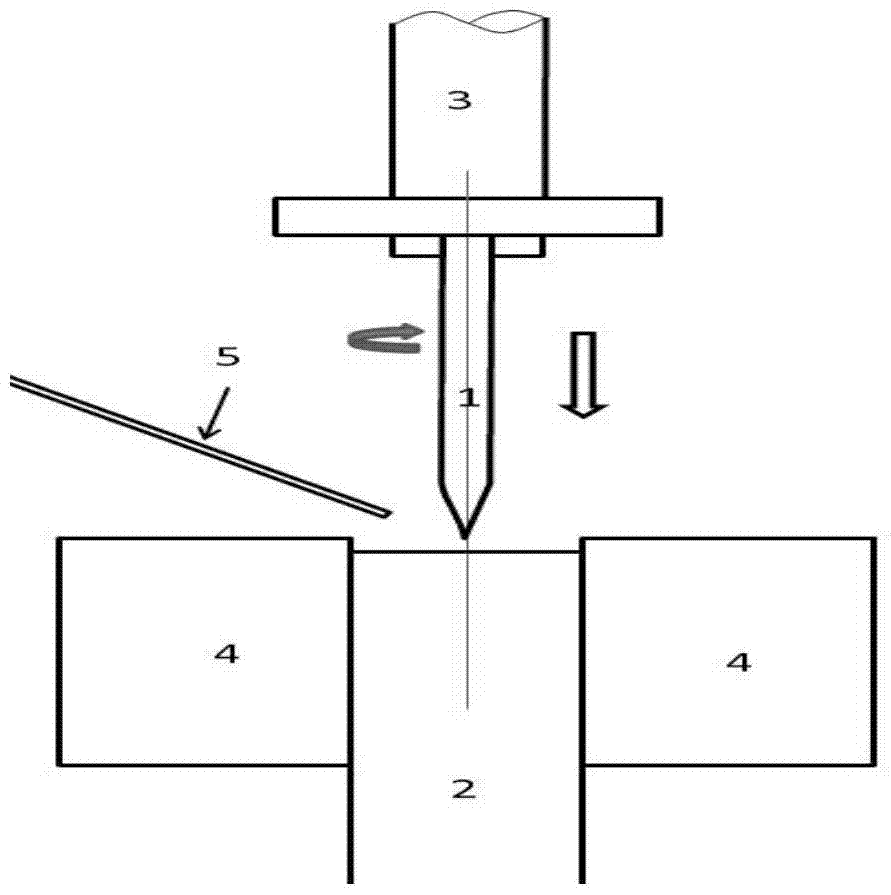

Embodiment 1

[0023] Fasten the iron core 1 on the rotating shaft 3, turn the front end of the iron core 1 into a cone shape, the cone angle is 0.5π, and the iron core about 5mm; at the same time, fix the magnesium anode rod 2 in the fixture 4 with a circular groove; open the valve of the protective gas guide pipe 5 to make the SF 6 +CO 2 The mixed gas covered the surface of the magnesium anode rod 2, where SF 6 :CO 2 =1:100 (volume ratio), the flow rate is about 0.01L / min, continuous air supply; the motor is turned on to drive the rotating shaft 3 to rotate at a high speed, the speed of the iron core 1 is kept at about 2400r / min, and the iron core 1 is on the rotating shaft 3 Driven by it, it moves vertically downward at a speed of about 2mm / s until the iron core 1 is implanted into the rod about 25mm; after the magnesium liquid on the magnesium anode rod 2 is solidified and cooled, take the welded magnesium anode rod 2 out to be assembled. The service life of sacrificial anode rods c...

Embodiment 2

[0025] Fasten the iron core 1 on the rotating shaft 3, and the front end of the iron core 1 is tapered, the cone angle is 0.5π, the iron core is about 8mm; at the same time, fix the magnesium anode rod 2 in the fixture 4 with a circular groove; open the valve of the protective gas guide pipe 5 to make the SF 6 +CO 2 The mixed gas covered the surface of the magnesium anode rod 2, where SF 6 :CO 2 =1:100 (volume ratio), the flow rate is about 0.008L / min, continuous air supply; the motor is turned on to drive the rotating shaft 3 to rotate at a high speed, the speed of the iron core 1 is kept at about 2800r / min, and the iron core 1 is on the rotating shaft 3 Driven by it, it moves vertically downward at a speed of about 5mm / s, until the iron core 1 is implanted into the rod about 25mm; after the magnesium liquid on the magnesium anode rod 2 is solidified and cooled, take the welded magnesium anode rod 2 out to be assembled. Compared with the traditional adhesive connection m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com