A kind of nylon material assembly for laser welding and its preparation method and application

A technology of laser welding and assembly, which is applied in the field of nylon material assembly for laser welding and its preparation, can solve the problems of weak light energy, failure to actually verify the rupture strength of nylon material laser welding, and inability to reach the energy strength of nylon in a molten light absorbing layer. , to achieve the effect of consistent color, improved light transmittance and consistent formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

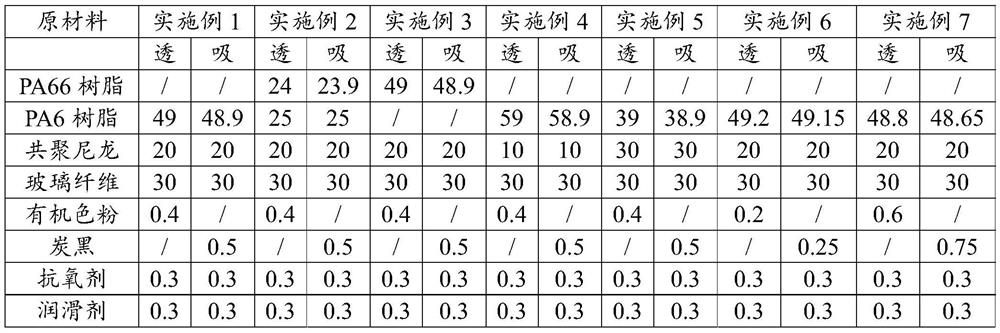

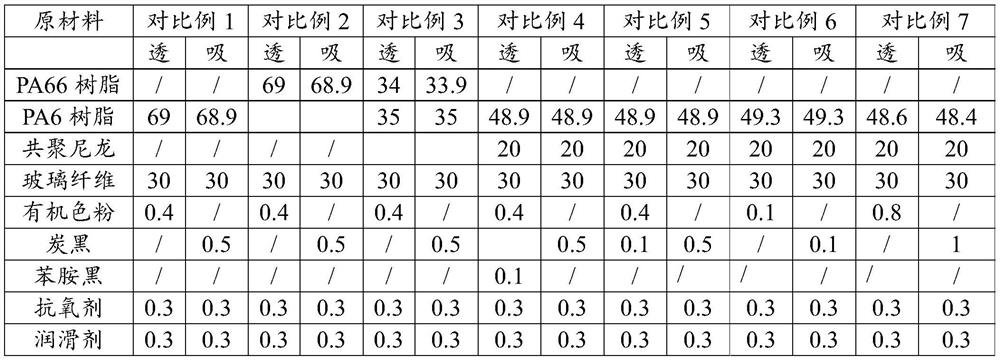

Embodiment 1~7 and comparative example 1~7

[0035] Its preparation method of embodiment 1~7 and comparative example 1~7 is as follows:

[0036] PA66 resin, PA6 resin, copolymerized nylon, carbon black, antioxidant and lubricant are pre-mixed in a certain proportion in a high-mixing medium, and then melted and extruded into a twin-screw extruder. , cooling, pelletizing, and drying to obtain the nylon material of the light-absorbing layer;

[0037] PA66 resin, PA6 resin, copolymerized nylon, organic toner, antioxidant and lubricant are pre-mixed in a certain proportion in a high-mixing medium, and then melted and extruded into a twin-screw extruder. After stripping, cooling, pelletizing and drying, the nylon material of the light-transmitting layer is obtained. The temperature of the twin-screw extruder is set at 220-260° C., and the screw speed is 350-450 rpm.

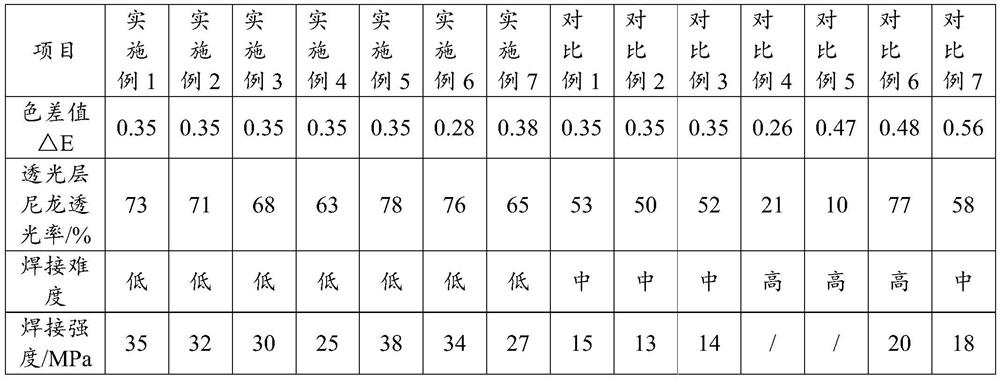

[0038] Embodiment 1~7 and comparative example 1~7 performance test method are as follows, and the results are as shown in table 3:

[0039] Color difference t...

Embodiment 2

[0046] Embodiment 2 added 20% copolymerized nylon on the basis of comparative example 2, which improved the light transmittance of nylon in the light-transmitting layer, and the corresponding welding strength also greatly improved, and realized the laser welding of nylon materials with PA66 as the matrix;

Embodiment 3

[0047] In Example 3, 20% copolymerized nylon was added on the basis of Comparative Example 3, which improved the light transmittance of nylon in the light-transmitting layer, and the corresponding welding strength was also greatly improved, realizing the laser welding of nylon materials based on PA6 and PA66 alloys. welding;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com