Tab laser welding method

A laser welding and lug technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as droplet splashing, poor battery K value, short circuit of the battery cell, etc., to avoid droplet splashing, welding surface Smooth and flat without spatter particles, the effect of weld sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

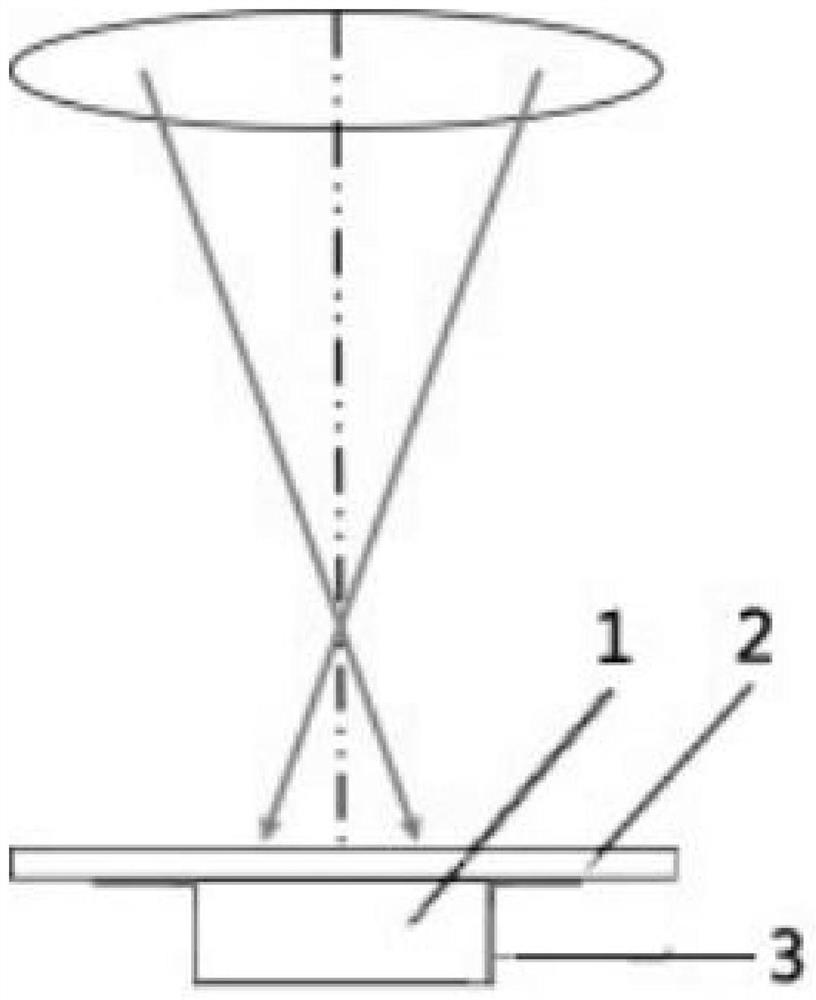

[0046] A tab laser welding method, comprising the following steps:

[0047] Step (A): unwinding the tab piece 1;

[0048] Step (B): placing the unrolled tab piece 1 on the base;

[0049] Step (C): Place the tab piece 1 on one surface of the foil material 2 to be welded and stick it closely, and the overlapping area of the tab piece 1 and the foil material 2 to be welded is recorded as the welding area;

[0050] Step (D): using a sealant 3 to seal and bond the contact edges of the tab 1 and the foil 2 to be welded to form a weldment;

[0051]Step (E): The weldment is flipped horizontally in situ, and a laser is used to perform laser welding on the welding area of the weldment.

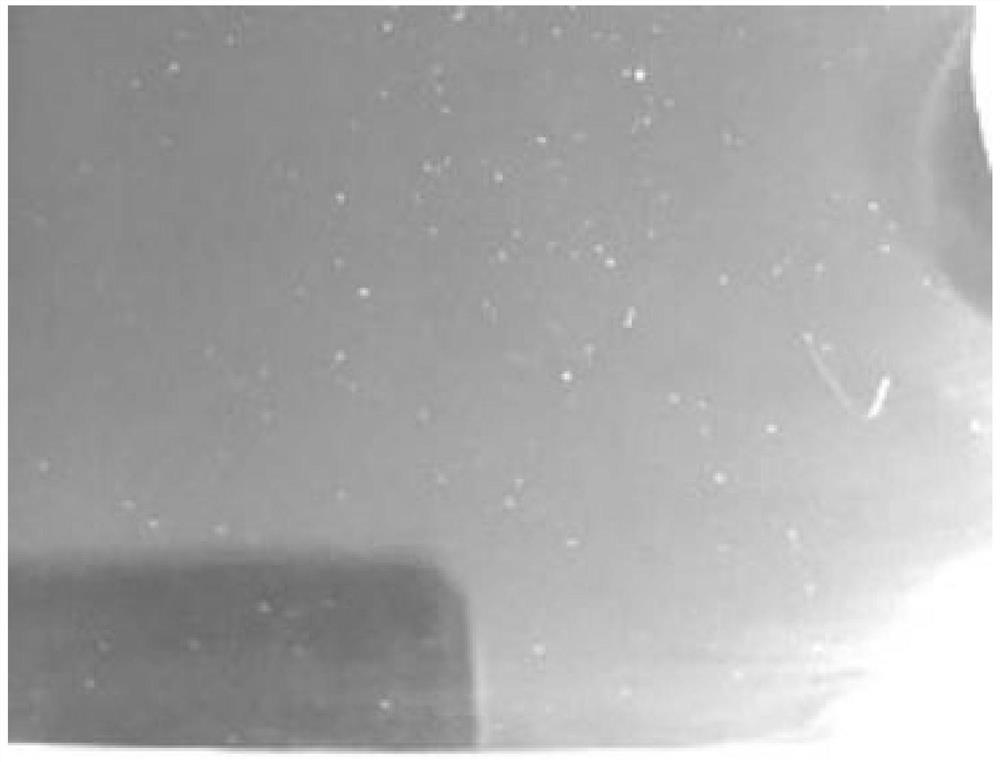

[0052] The flow chart of the current technology laser welding, before welding, the tabs and the foil are placed overlappingly, but because the tabs or the foil are not flat, there will be a gap between the two. When welding, the laser is directed to the welding area for laser heating, and the blac...

Embodiment 2

[0063] A tab laser welding method, comprising the following steps:

[0064] Step (A): unwinding the tab piece 1;

[0065] Step (B): placing the unrolled tab piece 1 on the base;

[0066] Step (C): Place the tab piece 1 on one surface of the foil material 2 to be welded and stick it closely, and the overlapping area of the tab piece 1 and the foil material 2 to be welded is recorded as the welding area;

[0067] Step (D): using a sealant 3 to seal and bond the contact edges of the tab 1 and the foil 2 to be welded to form a weldment;

[0068] Step (E): The weldment is flipped horizontally in situ, and a laser is used to perform laser welding on the welding area of the weldment.

[0069] Wherein, there is a step (d1) between the step (D) and the step (E): using a detection device to detect the sealant 3 attached to the surface of the weldment.

[0070] Wherein, the detection device is an industrial camera.

[0071] Wherein, the material of the foil material is copper foi...

Embodiment 3

[0079] A tab laser welding method, comprising the following steps:

[0080] Step (A): unwinding the tab piece 1;

[0081] Step (B): placing the unrolled tab piece 1 on the base;

[0082] Step (C): Place the tab piece 1 on one surface of the foil material 2 to be welded and stick it closely, and the overlapping area of the tab piece 1 and the foil material 2 to be welded is recorded as the welding area;

[0083] Step (D): using the sealant 3 to seal the contact edge of the tab piece 1 and the foil to form a weldment;

[0084] Step (E): The weldment is flipped horizontally in situ, and a laser is used to perform laser welding on the welding area of the weldment.

[0085] Wherein, there is a step (d1) between the step (D) and the step (E): using a detection device to detect the sealant 3 attached to the surface of the weldment.

[0086] Wherein, the detection device is an industrial camera.

[0087] Wherein, the material of the foil material is tin foil, and the thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com