Radiating bracket for placing cylindrical batteries in cylindrical battery pack

A cylindrical battery and heat dissipation bracket technology, applied in battery pack components, secondary batteries, circuits, etc., can solve problems such as affecting battery life, difficult to monitor battery temperature, and inability to effectively take away battery heat, to prevent heat accumulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

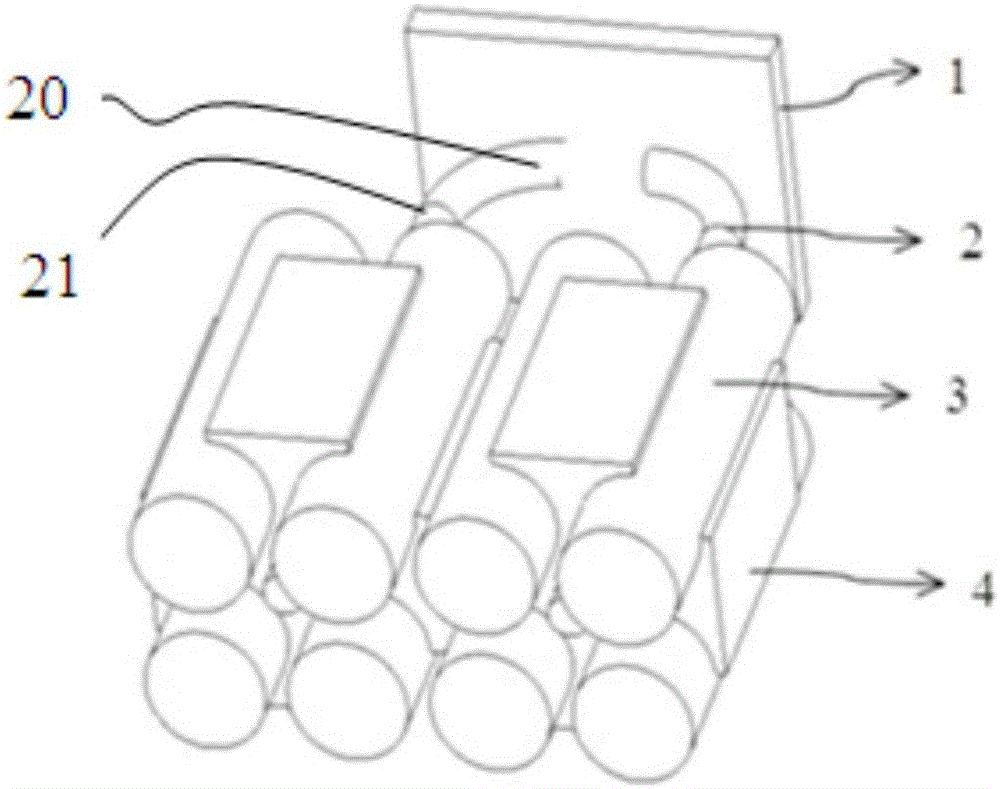

[0021] Such as figure 1 As shown, the cylindrical battery pack of the present invention includes an aluminum substrate 1 , a heat pipe 2 , a cylindrical battery 3 and a cooling bracket 4 . The shape of the cylindrical battery 3 is cylindrical, the outer layer is wrapped by an insulating film, and the two ends are positive tabs and negative tabs respectively. The heat dissipation bracket 4 is made of industrial pure aluminum, which not only has good thermal conductivity but also has certain hardness.

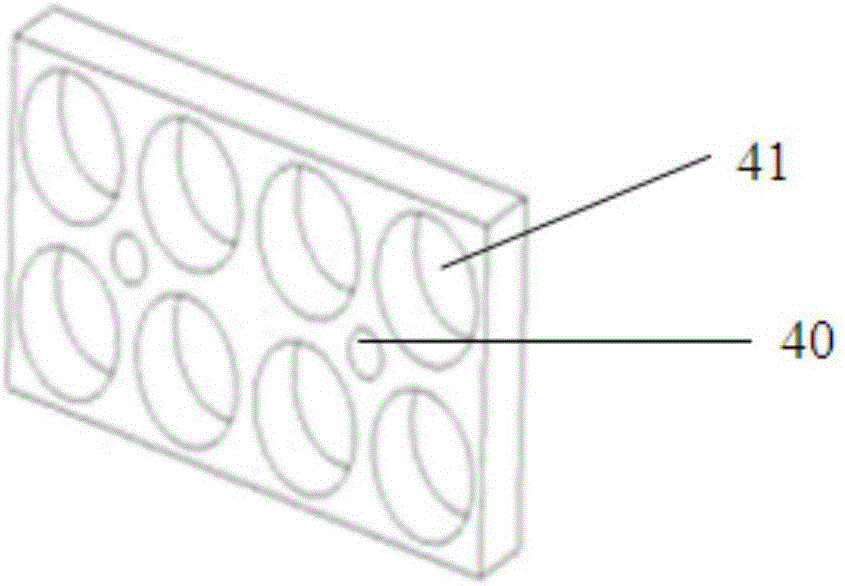

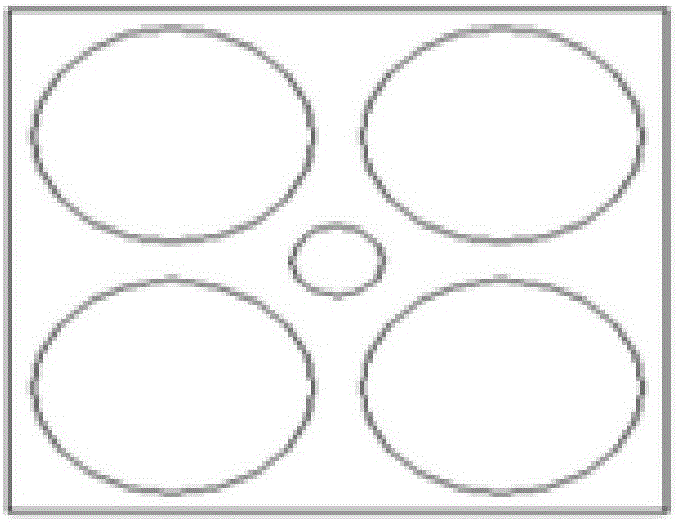

[0022] The cooling bracket 4 is provided with a through hole 40, the extension direction of the through hole 40 is consistent with the extension direction of the cylindrical battery 3, and a positioning part 41 for placing the cylindrical battery 3 is formed around the through hole 40. The role of the positioning part 41 is as follows: The purpose is to position the cylindrical battery 3 , and the second is that the heating surface of the cylindrical battery 3 is in close contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com