Preparation method and application of through-hole phase transfer type ipmc with pvdf/pvp/il as base membrane

A base film and phase transfer technology, applied in the direction of coating, etc., can solve the problems of small mechanical properties, short displacement period, and short displacement distance, and achieve the effects of weight reduction, low energy consumption, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

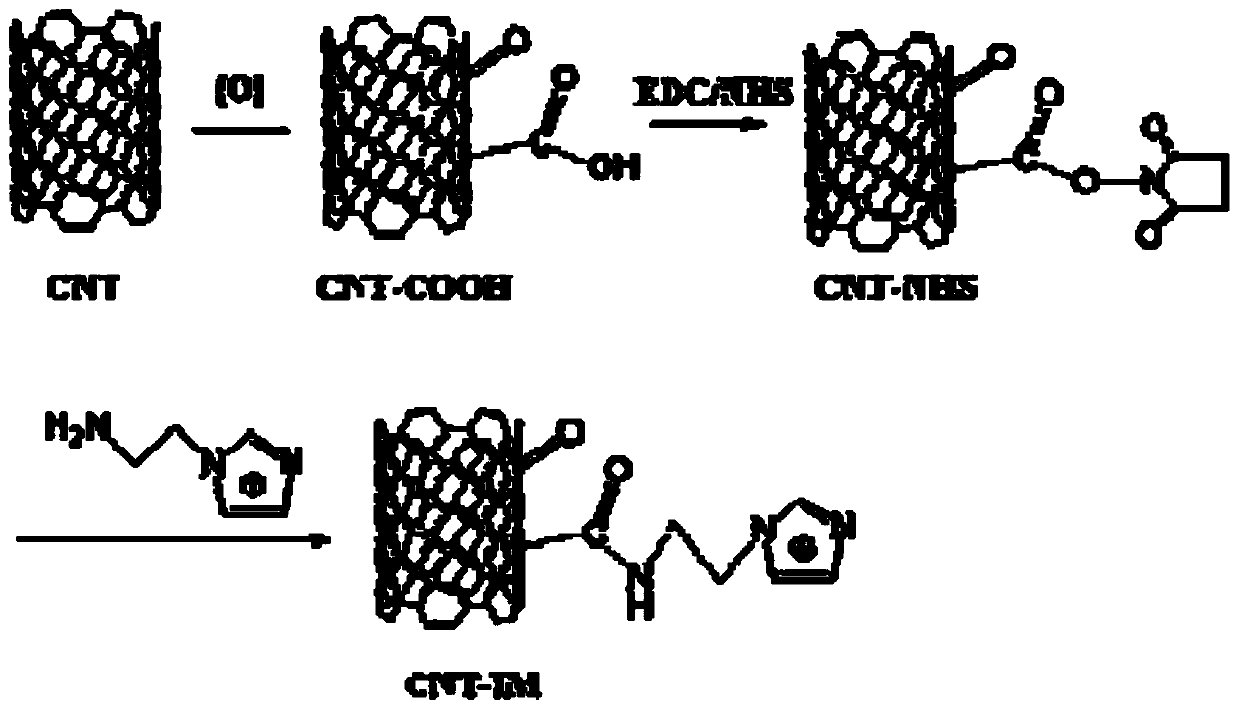

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 (casting method prepares basement membrane)

[0046] Prepare the basement membrane of IPMC by casting method: weigh 2.196g PVDF solution, 0.3876gPVP and 20mlDMF solvent in a beaker, add 1ml1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid, mix and stir evenly, and The mixed film solution is pumped with low pressure to bubble, and then the solution with pumped bubbles is placed in the air for one minute to obtain a film solution, and then the film solution is spread on a glass slide to be flattened, and dried in an oven at 70°C for 6 hours , to prepare PVDF / PVP / IL basement membrane.

Embodiment 2

[0047] Embodiment 2 (preparation of basement membrane by phase transfer mode)

[0048] Prepare PVDF / PVP / IL basement membrane by phase transfer method: weigh 2.196g PVDF powder (14% of solution quality), 0.3876g PVP powder (15% of PVDF powder content) and 20mlDMF solvent in a beaker, then add 1ml ionic liquid , mechanically stirred at 60°C for 10 hours, after mixing evenly, remove the air bubbles from the mixed membrane solution in vacuum, then put the solution with bubbles in the air and let it stand for one minute to obtain a transparent and uniform casting solution. The PVDF / PVP / IL casting solution is quantitatively dropped on the glass plate, and then spread evenly on the glass plate on the glue homogenizer to obtain a film solution with uniform thickness, and then stay in the air for 30s, then put it in 20% ethanol In the coagulation solution, the phase inversion process is completed to precipitate and form a film, and the thickness of the obtained film is about 100-800 mi...

Embodiment 3

[0049] Embodiment 3 (preparation through-hole casting type IPMC base film)

[0050] Choose the sodium chlorate solution that secondary concentration is 5000ppm to remove the pore-forming agent PVP in the PVDF / PVP / IL casting film, the PVDF / PVP / IL casting film that example 1 obtains is made into 2x2cm shape, it is put into the prepared The concentration is 5000ppm sodium hypochloride solution, heated at 50°C, soaked for 3 days, then rinsed with ionized water three times after taking it out, soaked in deionized water for 6 hours, and dried in an oven at 70°C. The through-hole IPMC base film with high-performance actuation type we need is made.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com