Continuous circulation production process for sweet corn threshing assembly line

A sweet corn grain and production process technology, applied in the field of quick-frozen sweet corn assembly line production technology, can solve the problems of low production efficiency, high labor intensity, difficulty in adapting to the mass production requirements of quick-frozen sweet corn assembly line operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

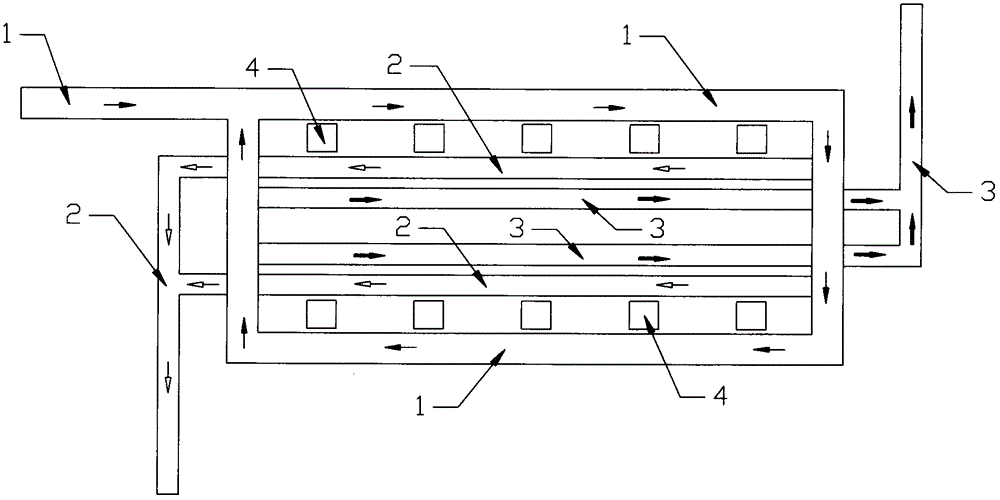

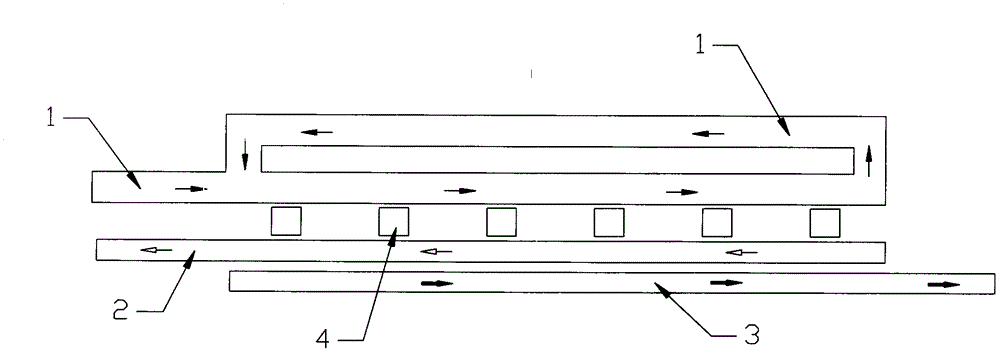

[0007] The present invention is described in conjunction with accompanying drawing: as attached figure 1 , In an enterprise with a daily production capacity of more than 100 tons of sweet corn raw materials, more than ten threshers 4 are used to process the light corn cobs after peeling, and four conveyor belts are used to connect the light corn cob conveyor belts 1 into a square continuous The circulation line is connected with three corncob conveyor belts 3 to send away the threshed corncobs, and three corncob conveyor belts 2 are used to pick up and send the mechanically threshed sweet corn kernels to the next process. as attached figure 2 If the raw material of sweet corn is less than 100 tons, an enterprise that uses about six threshing machines 4 to process the light corn cobs after peeling, uses two smooth corn cob conveyor belts 1, and at the same time adds an inclined funnel to put the light corn cobs. The corn cob conveyor belt 1 is connected to form a continuous c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com