Automatic glue filling production line and method of fine filters for filtrating absorbers

A filter absorber and fine filter technology, which is applied to the automatic glue filling production line and the glue filling field of the fine filter used in the filter absorber, can solve the problems of difficult to maintain on-site sanitation, large differences in quality consistency, and greater harm to personnel health, and achieve easy Achieving and controlling effects with a simple form factor that is not easily disturbed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

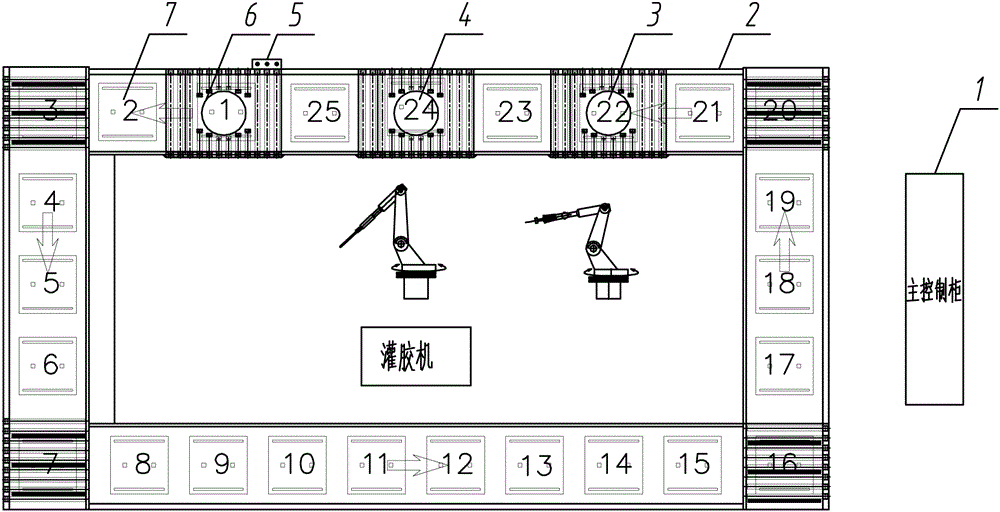

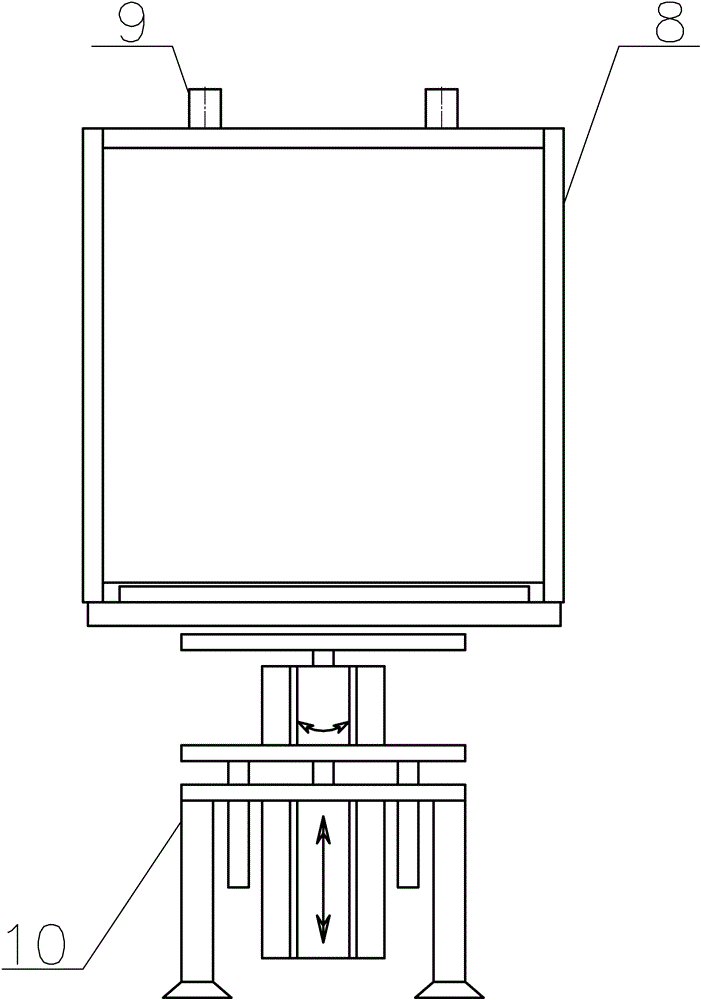

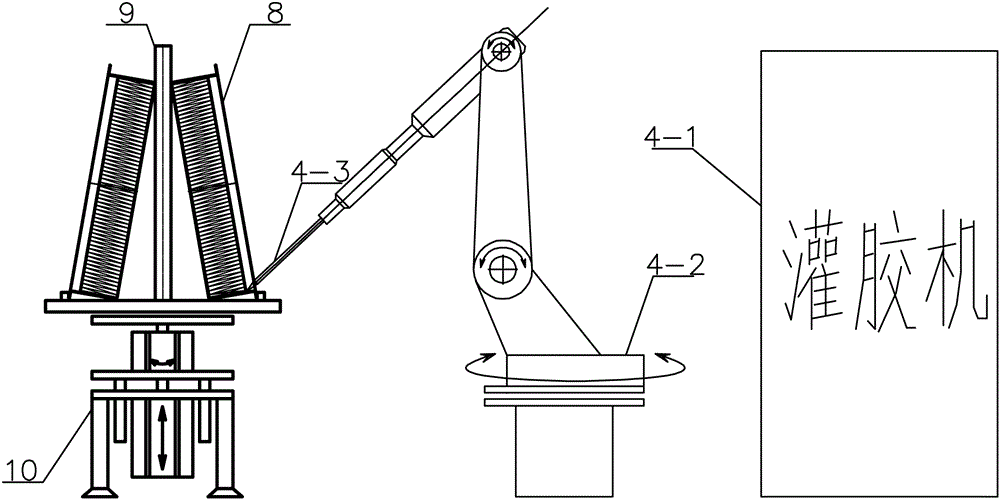

[0044] Such as Figure 1-7 As shown, an automatic glue filling production line for fine filters for filter absorbers, which includes a main control cabinet 1, a roller conveyor line 2, a turning station 3, a glue filling station 4, a manual button 5, an on-line station 6, and a transfer station Position 7, fine filter 8, tray 9, rotary lifting platform 10, compressed air pipelines and connecting cables, a transfer station is set between the turning station 3 and the glue filling station 4, and the grouting station 4 There is also a transfer station between the on-line station 6, and the entire production line adopts a ring structure and connects all stations with a roller conveyor line 2, and a pallet 9 is placed on each station; A turning robot 3-1 is arranged on the side of the turning station 3, and a glue filling machine 4-1 is arranged on the side of the grouting station 4. The main control cabinet 1 supplies power for the production line, and centrally controls the elec...

Embodiment 2

[0055] Adopt above-mentioned automatic glue filling production line to carry out fine filter automatic glue filling method, it comprises the following steps:

[0056] S1: The fine filter 8 is on-line. When the fine filter 8 is on-line, the production line runs semi-automatically, and the on-line is carried out on the on-line station 6. At this time, press the "on-line" on the manual button 5, and the lifting disc 10-4 drives the tray 9 Automatically ascend, manually put a fine filter 8 on the tray 9, make the rear of the fine filter shell 8-3 lean against the column 9-2, and the bottom lean against the positioning bar 9-1; after completion, press the manual button 5 "Rotate" on the top, the rotating disk 10-3 drives the tray 9 to automatically rotate 180 degrees, and manually put another fine filter 8 on the tray 9; The disc 10-4 drives the tray 9 to automatically descend, and then the roller conveying line 2 automatically transfers the tray 9 to the next station, and so on, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com