Inter-rack technical roller replacement device and method

A technology between process rolls and stands, which is applied in the direction of metal rolling stands, manufacturing tools, metal rolling mill stands, etc., can solve the problems of smashing people and stand equipment, low operating efficiency, and high labor intensity, and achieves a solution damage, increase operating rate, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

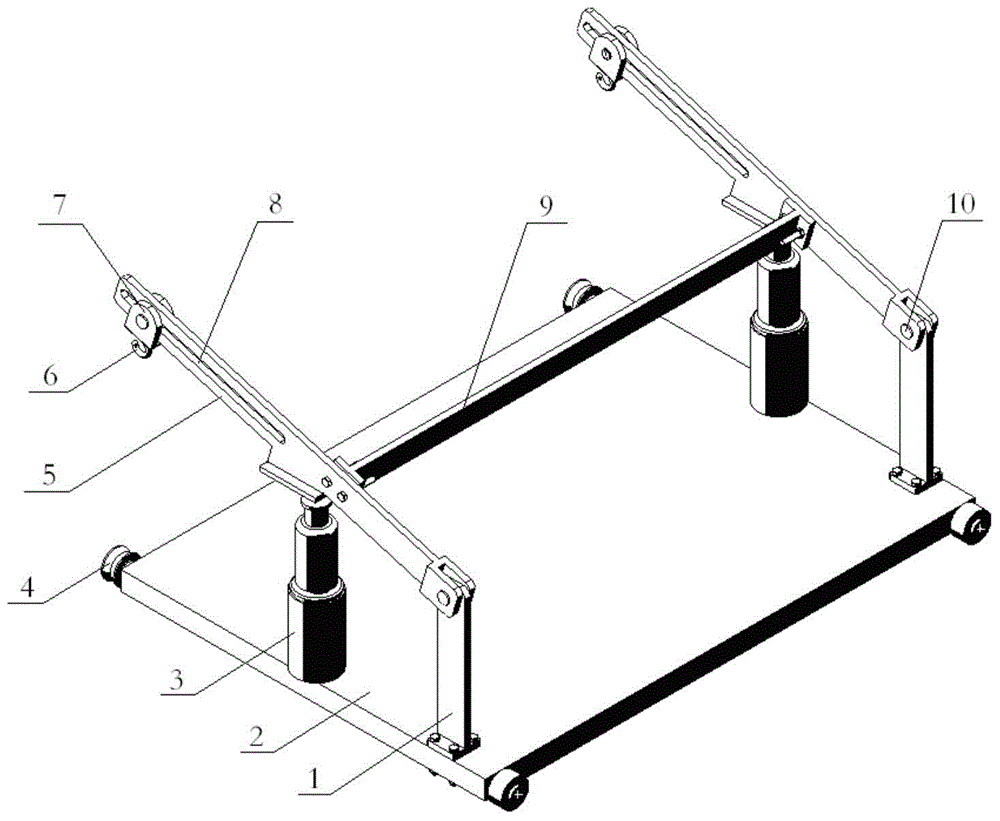

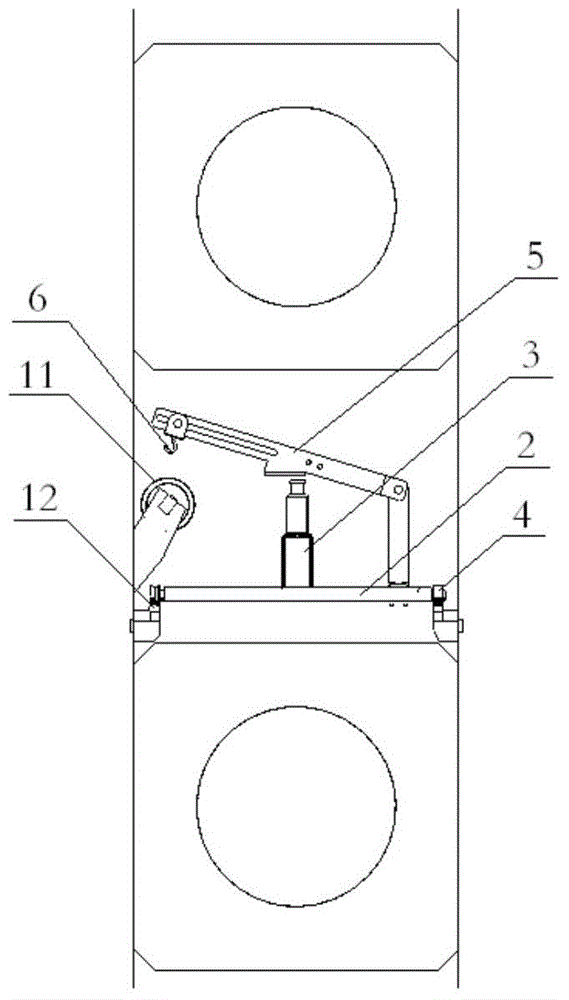

[0020] Depend on figure 1 It can be seen that the inter-frame process roll replacement device of the present invention is mainly composed of a pull plate 1, a trolley 2, a jack 3, an arm 5, a hook 6, a slide block 7, a crossbeam 9 and a bearing pin 10. The trolley 2 is a rectangular flat plate, and the four corners of the trolley 2 are respectively equipped with rail wheels 4. The two sides of the upper surface of the trolley 2 are respectively fixed with a pull plate 1 by bolts, and one end of the hanging arm 5 is hinged with a pin 10. At the upper end of the pull plate 1, the middle parts of the two hanging arms 5 are connected together by a cross beam 9, and the two ends of the cross beam 9 are connected to the middle parts of the two hanging arms 5 with bolts respectively. The other side of the hanging arm 5 is provided with a chute 8 respectively, and a slide block 7 is slidably connected in the chute 8, and a hook 6 is provided below the slide block 7; There is a backin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com