Centering calibration method for rolling center line

A rolling centerline and calibration method technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of low rolling centerline accuracy, poor rolling mill centerline accuracy, and inaccurate measurement data. , to achieve the effect of reducing the generation of scrap steel pipes, improving product quality and accurate calibration data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The calibration method of the rolling center line of the present invention comprises two parts: measuring and centering of the rolling center line of the PQF continuous rolling mill and zero position calibration of the servo hydraulic cylinder of the rolling mill archway, and the specific methods and steps are as follows:

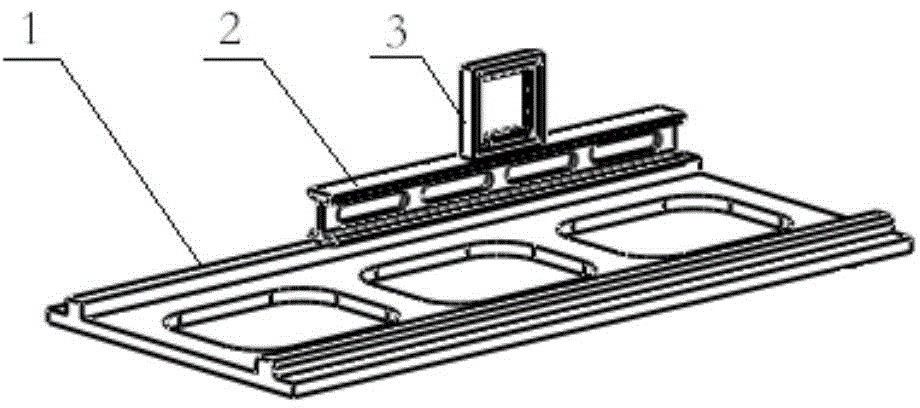

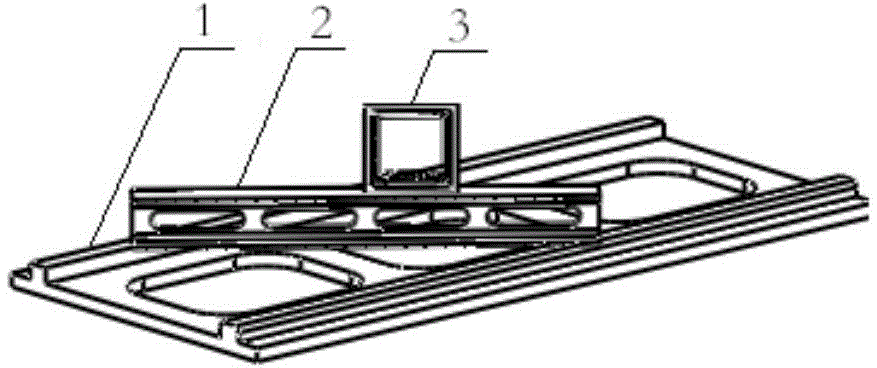

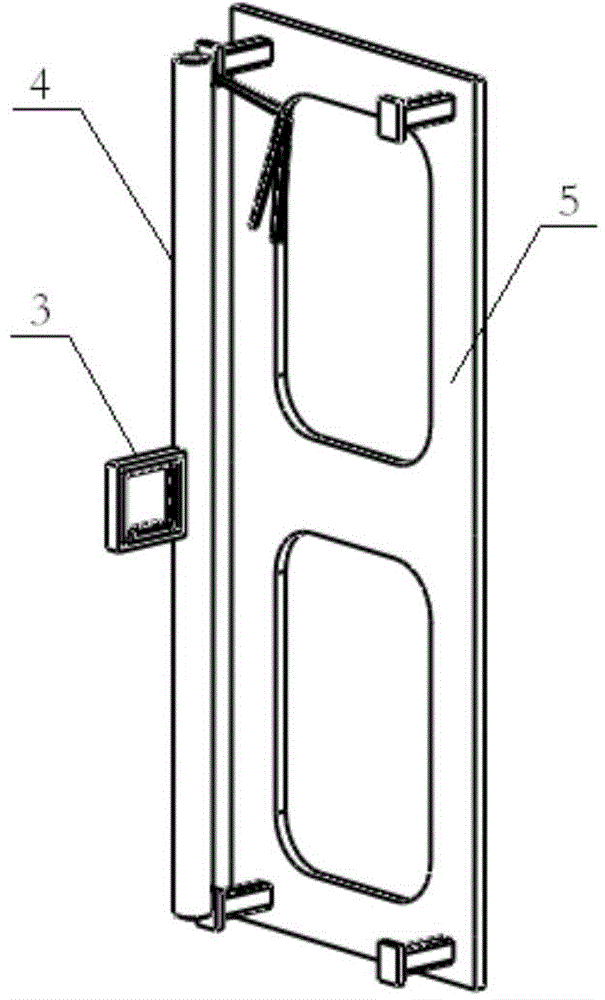

[0043] 1. Measurement and alignment of rolling center line of PQF continuous rolling mill

[0044] 1. First measure the flatness of a single guide rail 1 with the ruler 2 and the frame-type level meter 3, then use the ruler 2 and the frame-type level meter 3 to cross-measure the relative levelness of the two guide rails 1, and calculate the leveling of the continuous rolling mill archway according to the measurement data For the gasket thickness required for the inner guide rail 1, level the two guide rails 1 of each rack by adding or subtracting the gasket, so that the leveling error of guide rail 1 per meter δ≤±0.05mm.

[0045] 2. The measuring col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com