A kind of metal tube surface heat treatment equipment

A surface heat treatment, metal tube technology, applied in heat treatment equipment, heat treatment furnaces, furnaces, etc., can solve the problem of reduced toughness, difficult to meet the refinement requirements of medical small metal tubes, thin tube water droplet structure and cleanliness It is difficult to meet the surgical grade, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

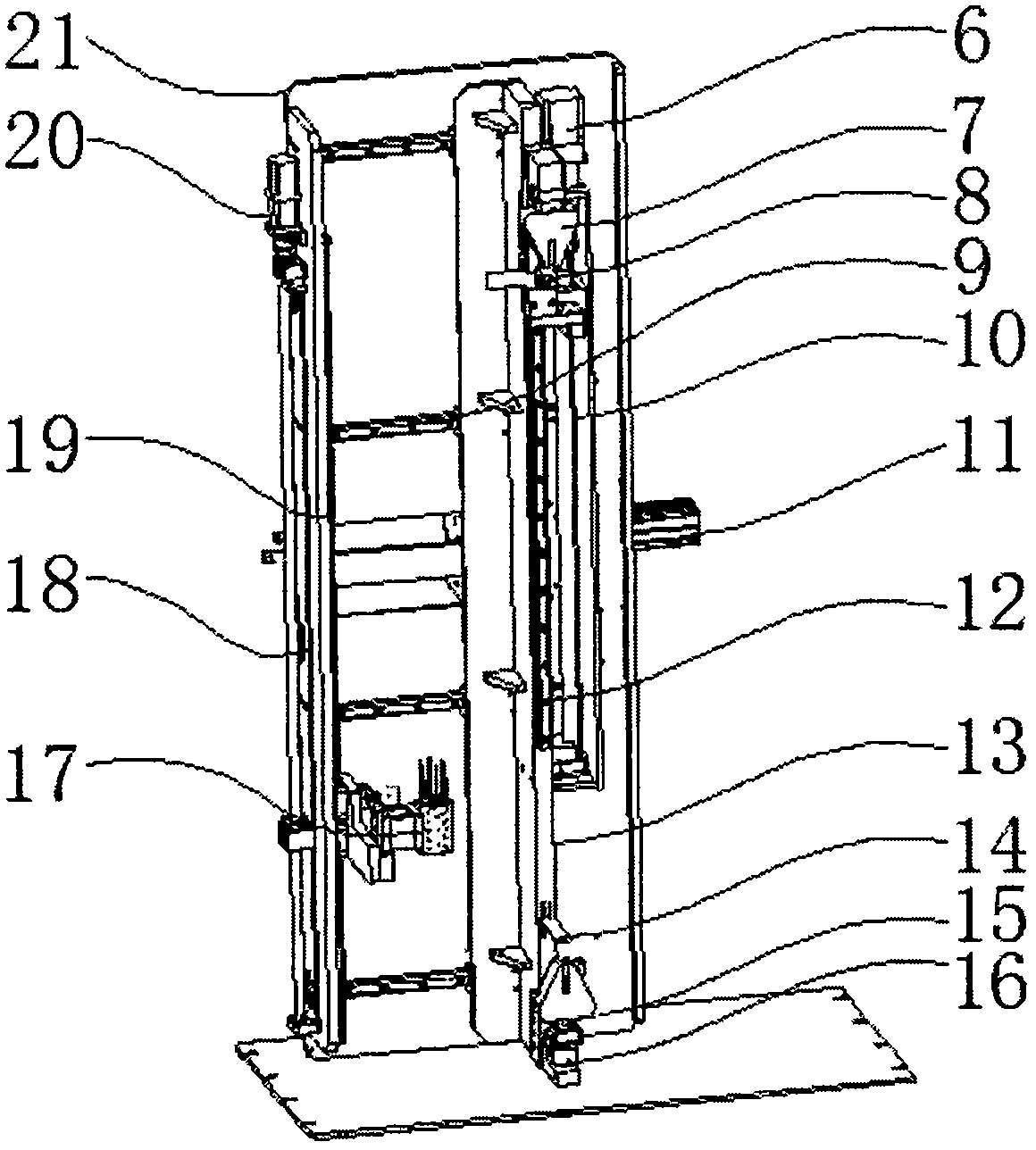

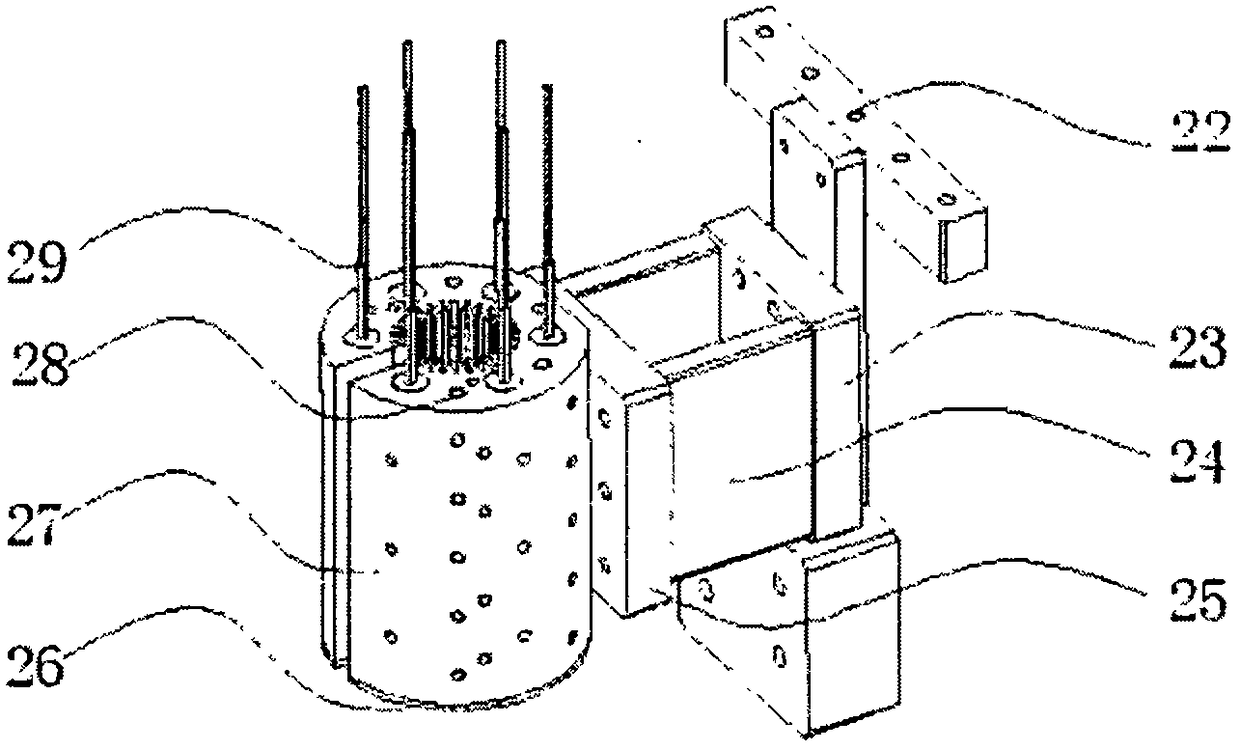

[0019] The following will be combined with figure 1 to attach Figure 4 The present invention is described further with embodiment, but should not limit protection scope of the present invention with this.

[0020] The invention provides a metal tube surface heat treatment equipment, which includes an equipment frame, a body structure arranged in the frame for supporting the metal pipe, a heating body structure arranged on one side of the body structure for heating the metal pipe, and an electric A control module connecting the body structure and the heating body structure for controlling the relative movement of the body structure and the heating body structure.

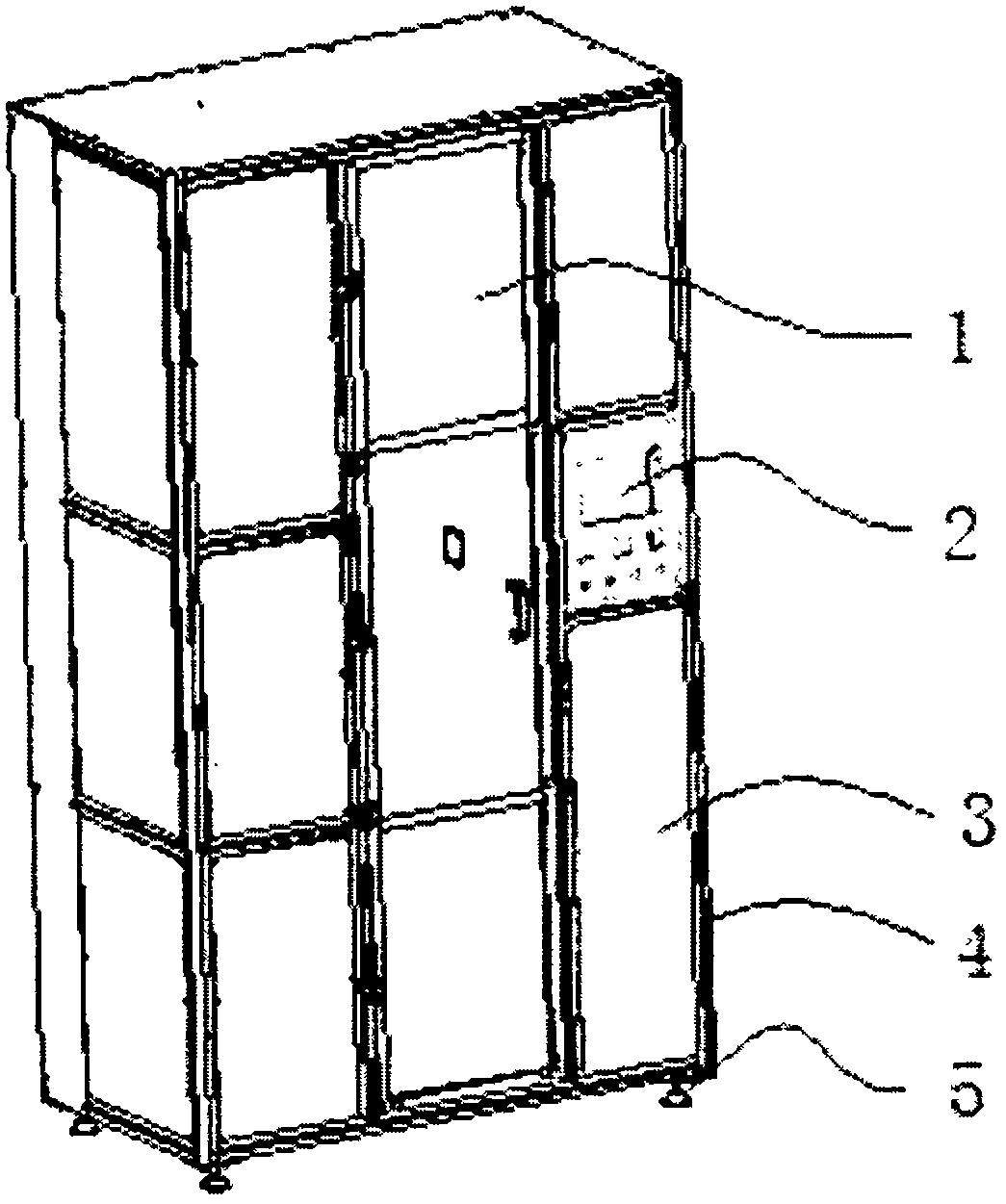

[0021] as attached figure 1 As shown, the front panel of the equipment rack includes a safety door 1 for replacing metal pipes, a side wall for placing an electric control box 3 for a control module, and an operation panel 2 for electrically connecting the control module; the equipment The bottom surface of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com