Notebook computer assembly line

A notebook computer and production line technology, applied in the direction of assembly machines, electrical digital data processing, instruments, etc., can solve the problems that the main line body cannot be segmented, low production capacity, and one-time handling, etc., to achieve reasonable structure, maintain logistics, and structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

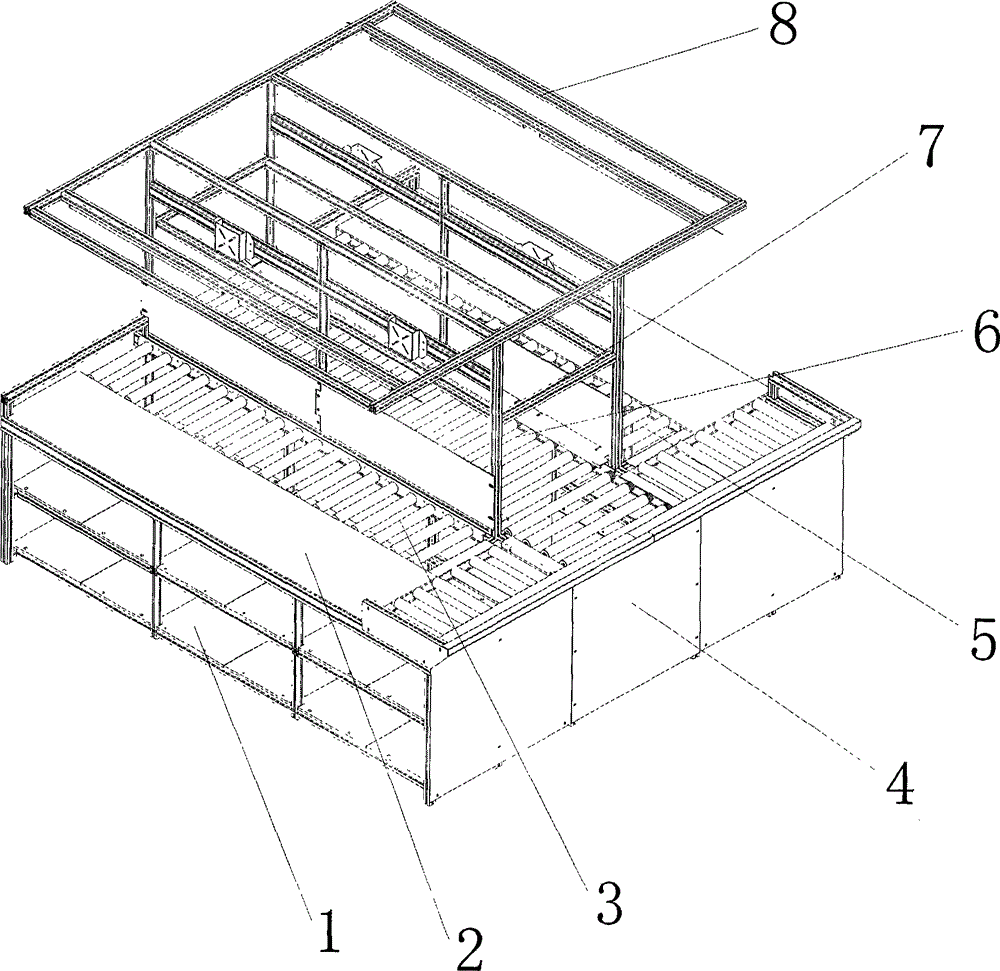

[0014] Such as figure 1 As shown, a notebook computer assembly production line includes a frame 4, a main line mechanism is provided in the middle of the frame 4, and secondary line mechanisms are provided on both sides of the frame. The main line mechanism includes three layers, including the bottom return line 6 , the intermediate material delivery line 7 , and the top layer finished product delivery line 8 .

[0015] The auxiliary line mechanism includes a workbench 2 arranged on both sides of the frame, the middle of the workbench 2 is a conveying line 3, and the end of one side is a left and right conveying line 5.

[0016] A recovery device is arranged next to each working position on the workbench. The recovery device is a recovery cavity 1 arranged at the bottom of the frame.

[0017] The frame is provided with a controller, and sensors are respectively arranged on the conveying line, the left and right conveying lines, the bottom return line, the intermediate materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com