Hydraulically-driven shackle hook

A rotating hook and push-type technology, applied in the direction of load hanging components, safety devices, cranes, etc., can solve the problems of inability to ensure the balance of lifting operations, the rotation of the hook cannot be directly controlled, and cannot meet the requirements of use, etc., to achieve a reasonable design Novelty, precise and reliable hydraulic transmission, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

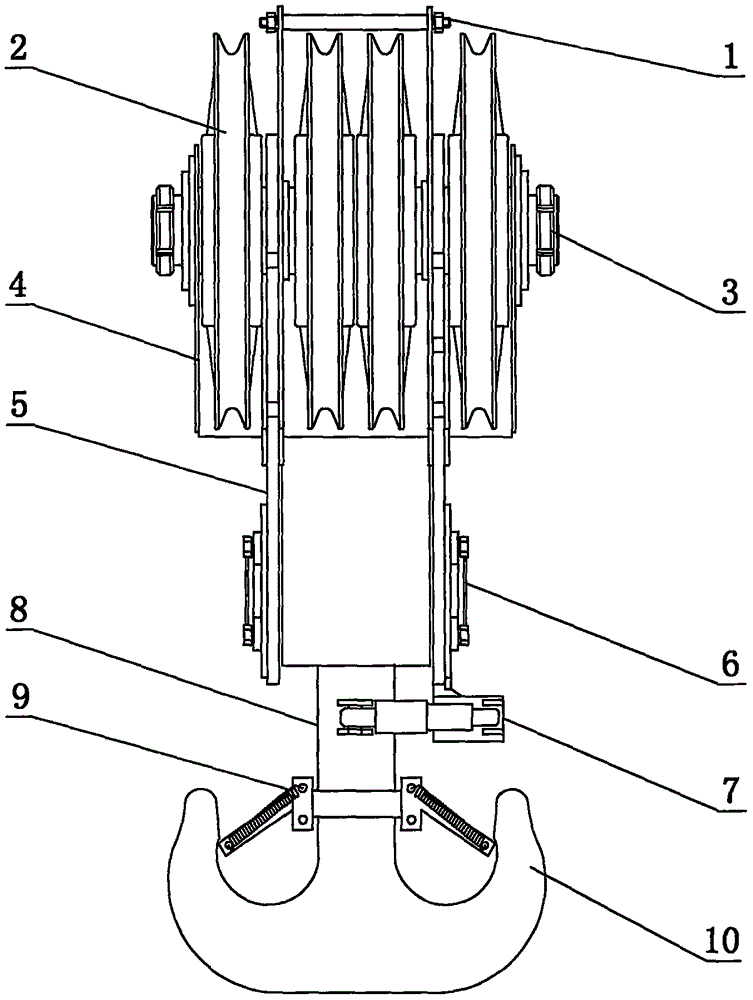

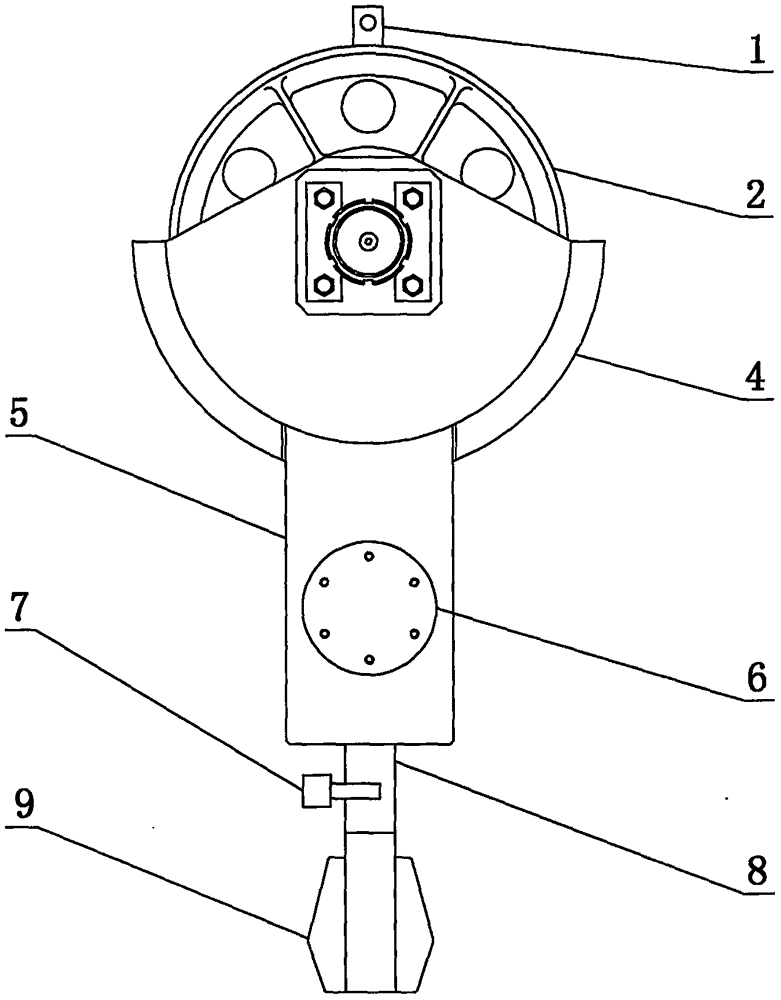

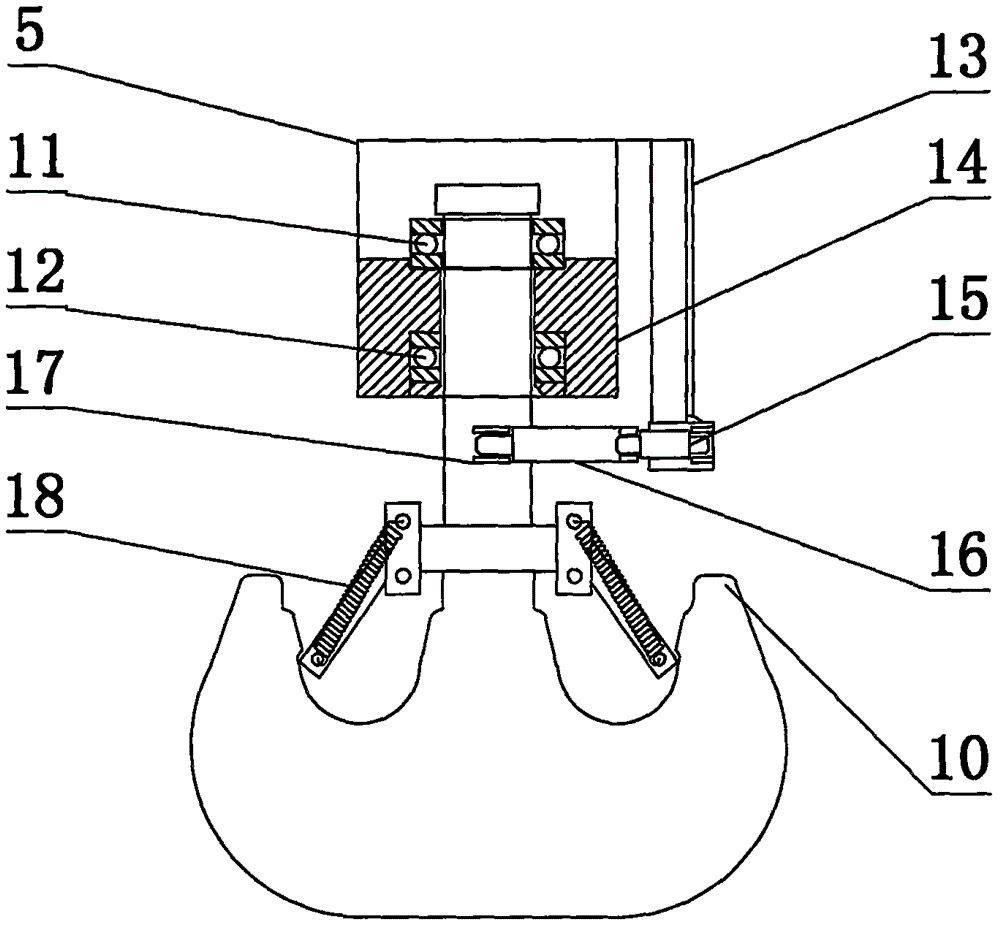

[0020] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a hydraulic push-type rotary hook includes a hook 8, a first bearing 11 is installed on the top of the hook 8, and a second bearing 12 is installed on the lower part of the first bearing 11, so A bearing fixing device 14 is mounted on the outside of the first bearing 11 and the second bearing 12, the bearing fixing device 14 is connected with a hook fixing device 5, and the outside of the hook fixing device 5 is mounted The end cover 6, the hook fixing device 5 is connected with a hydraulic device fixing frame 13, the hydraulic device fixing frame 13 is equipped with a hydraulic device 7, the hydraulic device 7 is provided with a hydraulic cylinder 15, the hydraulic The cylinder 15 is equipped with a solenoid valve, the solenoid valve is connected with a battery and a wireless signal receiver, the hydraulic cylinder 15 is connected with a connection 16, the connecting rod 16 is connected with a connection b...

Embodiment 2

[0023] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a hydraulic push-type rotary hook includes a hook 8, a first bearing 11 is mounted on the top of the hook 8, and a second bearing 12 is mounted on the lower part of the first bearing 11, so A bearing fixing device 14 is mounted on the outside of the first bearing 11 and the second bearing 12, the bearing fixing device 14 is connected to the hook fixing device 5, and the hook fixing device 5 is mounted on the outside The end cover 6, the hook fixing device 5 is connected with a hydraulic device fixing frame 13, the hydraulic device fixing frame 13 is equipped with a hydraulic device 7, the hydraulic device 7 is provided with a hydraulic cylinder 15, the hydraulic The cylinder 15 is equipped with a solenoid valve, the solenoid valve is connected with a battery and a wireless signal receiver, the hydraulic cylinder 15 is connected with a connection 16, the connecting rod 16 is connected with a connection base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com