Antioxidant composition, modified polyoxymethylene resin composition, modified polyoxymethylene resin and preparation method thereof

A technology of polyoxymethylene resin and composition, applied in the field of modified polyoxymethylene resin, can solve the problems of high price of antioxidants, affecting the production cost of POM, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

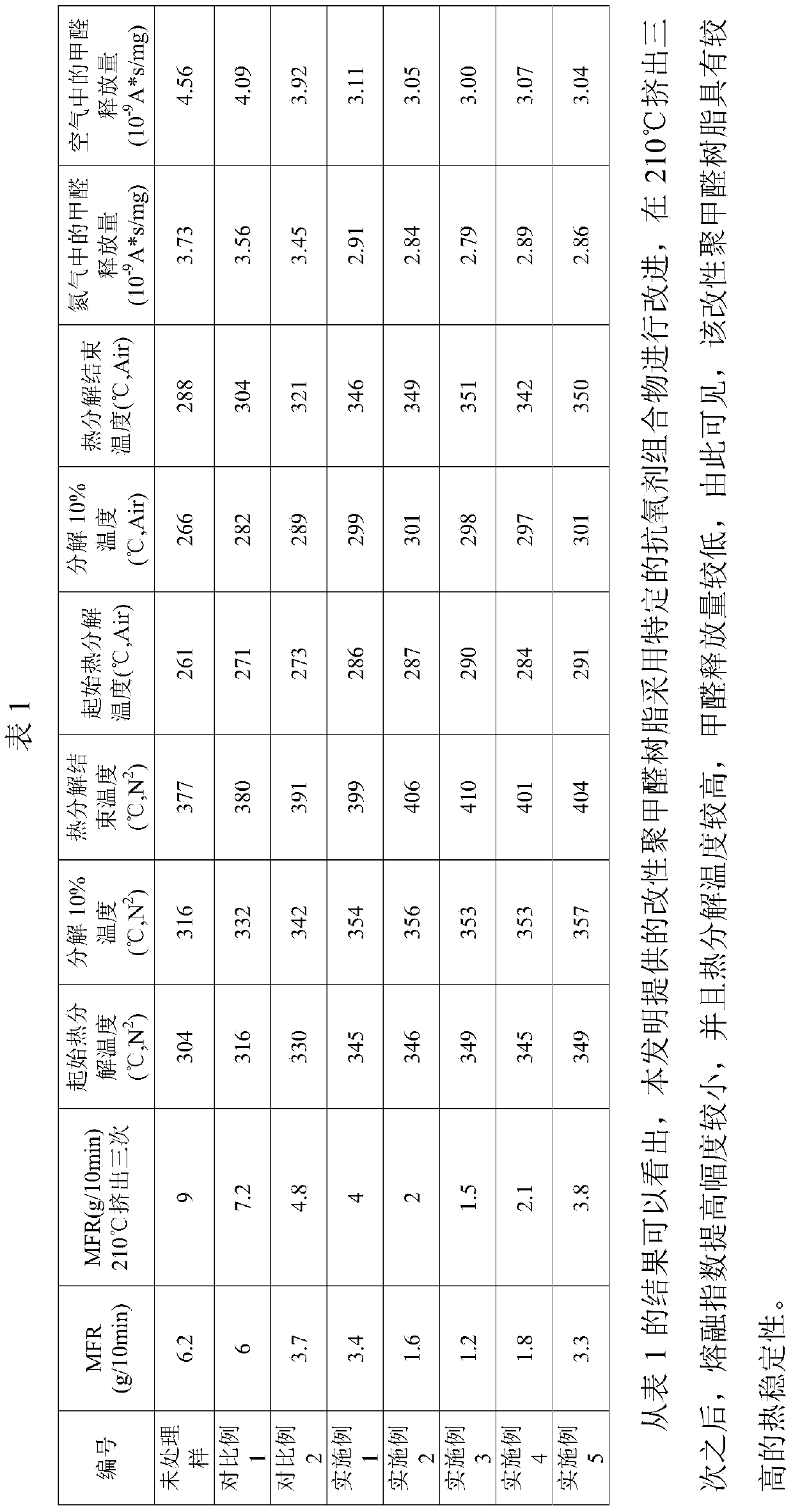

Examples

preparation example Construction

[0023] The preparation method of the modified polyoxymethylene resin provided by the present invention comprises melting, extruding and granulating the above-mentioned modified polyoxymethylene resin composition at 180-225° C., and then drying.

[0024] According to the preparation method of the modified polyoxymethylene resin provided by the present invention, the method also preferably includes mixing the components in the modified resin composition uniformly before melt extrusion granulation, which is more conducive to the Improvement of thermal stability of polyoxymethylene resin. The step of melt extrusion granulation can usually be carried out in an existing single-screw extruder or twin-screw extruder. In addition, the drying conditions generally include that the drying temperature may be 50-100° C., and the drying time may be 1-10 hours.

[0025] The present invention also provides the modified polyoxymethylene resin prepared by the above method.

Embodiment 1

[0028] This example is used to illustrate the antioxidant composition, the modified polyoxymethylene resin composition, the modified polyoxymethylene resin and the preparation method thereof provided by the present invention.

[0029]100 parts by weight of polyoxymethylene resin (purchased from Shenhua Ningxia Coal Group Coal Chemical Branch, brand name is MC90G, the same below), 2.1 parts by weight of diphenylmethane-4,4'-diisocyanate (MDI) (Alfa Aesar company, The same below), 1 part by weight of polyamide PA6 / 12 (purchased from EMS Swiss Chemical Co., Ltd., the brand is Grilamid, the same below), 0.1 part by weight of antioxidant 2-tert-butylhydroquinone (antioxidant TBHQ) , 0.4 parts by weight of tris (2,4-di-tert-butylphenyl) phosphite (antioxidant 168), 0.4 parts by weight of melamine, and 0.4 parts by weight of magnesium hydroxide are uniformly mixed and then used in a vented twin-screw extruder Melting extrusion granulation, the extrusion temperature is 180°C-225°C, th...

Embodiment 2

[0031] This example is used to illustrate the antioxidant composition, the modified polyoxymethylene resin composition, the modified polyoxymethylene resin and the preparation method thereof provided by the present invention.

[0032] 100 parts by weight of polyoxymethylene resin, 4 parts by weight of 2,4-toluene diisocyanate (TDI), (purchased from Alfa Aesar company, the same below), 0.5 parts by weight of polyamide PA6 / 12, 0.05 parts by weight of antioxidant Agent 2-tert-butylhydroquinone (antioxidant TBHQ), 0.25 parts by weight 1,3,5-trimethyl-2,4,6-(3,5-di-tert-butyl-4-hydroxybenzene Methyl)benzene (antioxidant 1330), 0.3 parts by weight of melamine, and 0.3 parts by weight of calcium stearate are uniformly mixed and then melted and extruded into pellets by a vented twin-screw extruder at an extrusion temperature of 180°C-225°C , the screw speed was 100 rpm, and after granulation, it was dried at 80° C. for 2 hours to obtain modified polyoxymethylene resin G2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com